Cleaning method for ceramic chip for glow discharge mass spectrometry equipment

A technology for glow discharge mass spectrometry and ceramic sheets, which is applied in the directions of cleaning methods, cleaning methods and utensils, chemical instruments and methods using liquids, etc., can solve the problems of low detection accuracy and detection efficiency of glow discharge mass spectrometry, and improve the The effect of detection accuracy and detection efficiency, reduction of impurity residues, and improvement of removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

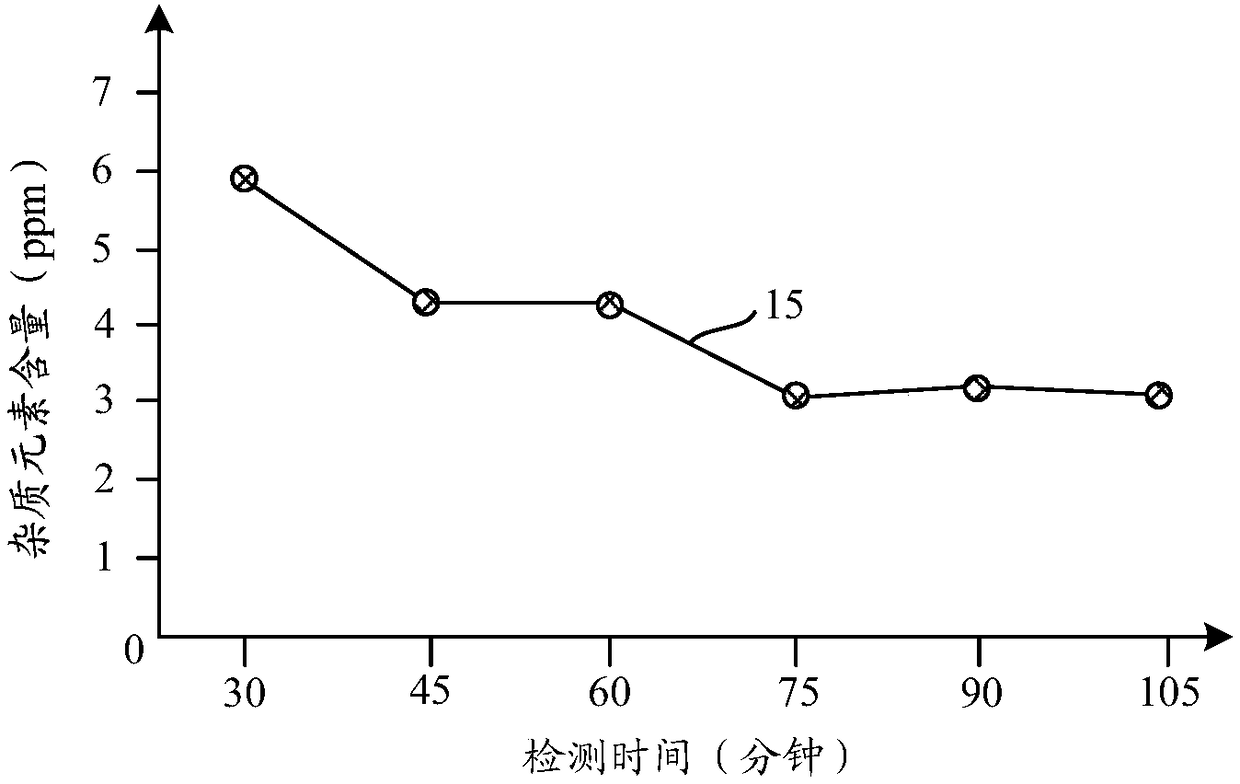

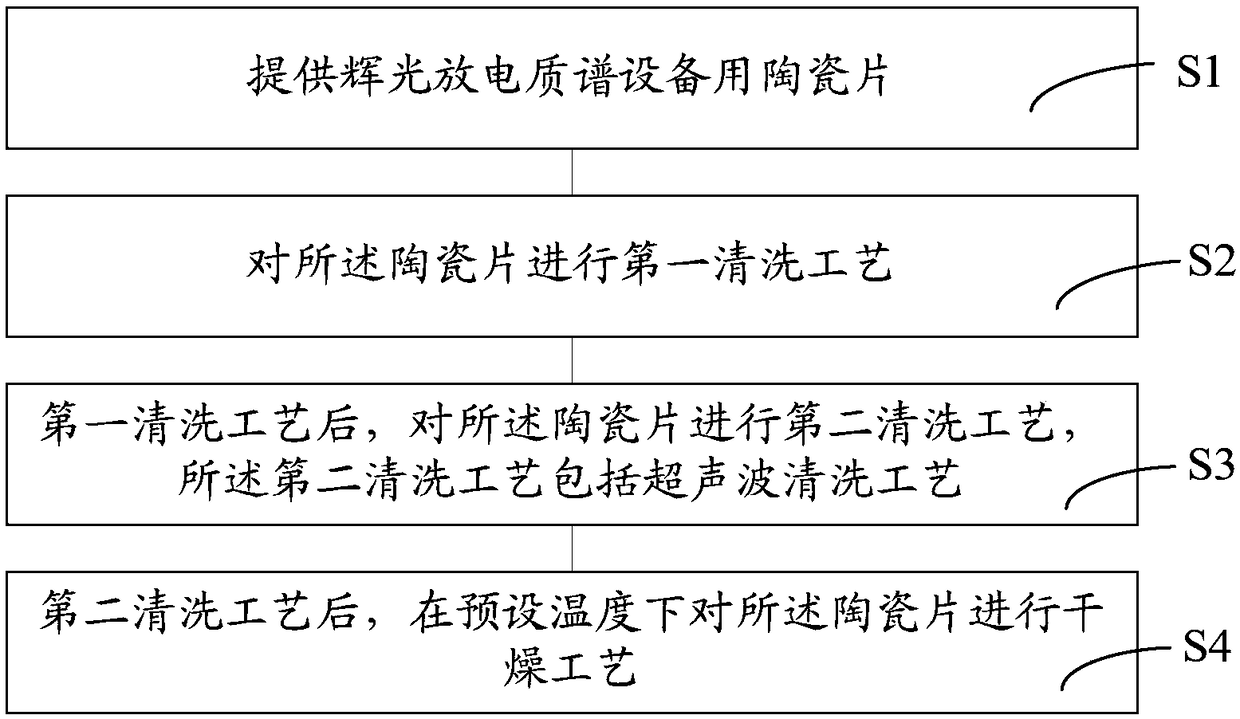

[0029] It can be seen from the background technology that the detection accuracy and detection efficiency of glow discharge mass spectrometry need to be improved. Analyze the reasons for this:

[0030] In the glow discharge mass spectrometry equipment, there are two ceramic sheets separated and arranged in parallel, and the ceramic sheets are located between the sample to be tested and the glow discharge ion source (GD source); in the glow discharge mass spectrometry equipment, the sample to be tested One side is the negative pole, and the other side of the glow discharge ion source is the positive pole. The ceramic sheet is used for insulation, that is, to isolate the positive pole and the negative pole, so as to prevent direct contact between the positive pole and the negative pole, thereby avoiding short circuit phenomenon.

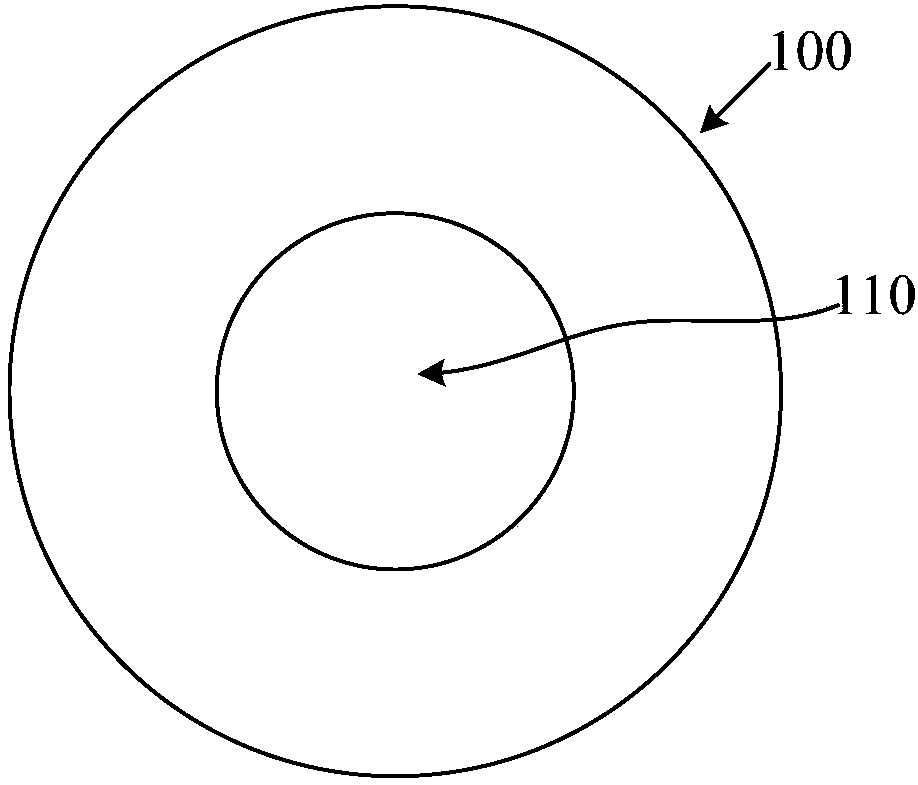

[0031] Wherein, the shape of the ceramic sheet is circular, that is, the center of the ceramic sheet has a through hole. During the detection process ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com