Integrated membrane biological reaction system

A technology of membrane biological reaction and filtration system, which is applied in sustainable biological treatment, biological water/sewage treatment, chemical instruments and methods, etc., can solve the problems of dynamic biofilm effluent water quality instability, high investment cost, high maintenance cost, etc. Achieve the effect of improving cleaning effect and reliability, low investment cost and low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

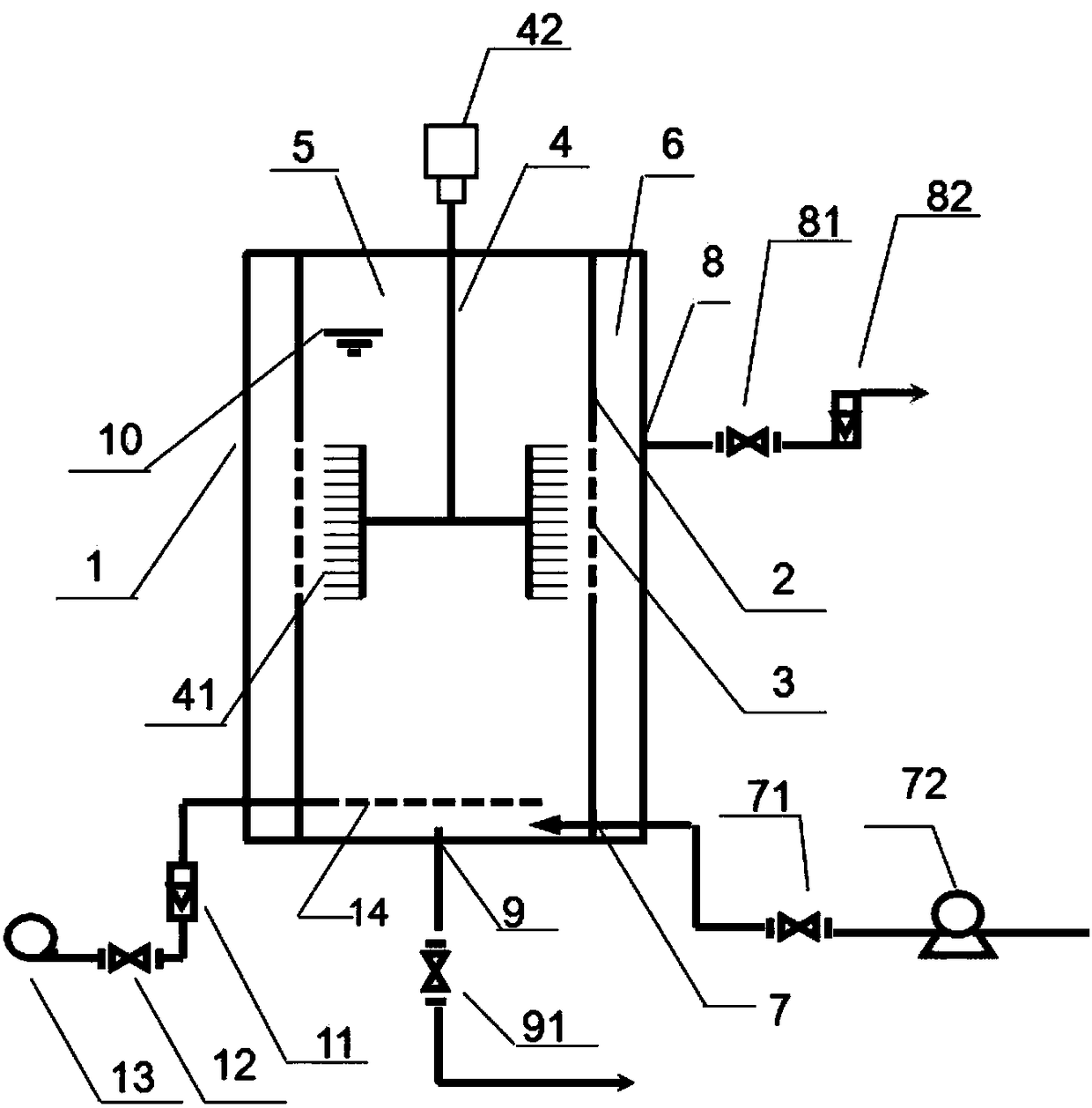

[0039] Such as figure 1 As shown, the integrated membrane bioreaction system (aerobic) is characterized in that it includes an outer shell 1, an inner shell 2, a filtration system 3 and a cleaning device 4, the inner shell 2 is arranged inside the outer shell 1, and the inner shell 2 The hollow part forms the first cavity 5, and the second cavity 6 is formed between the inner shell 2 and the outer shell 1; the filter system 3 is arranged on the inner shell 2, and the inner shell 2 and the outer shell 1 pass through the filter system 3 The cleaning device 4 is arranged inside the first cavity 5 , and the cleaning device 4 is used for cleaning the filter system 3 . The first cavity 5 is a membrane biochemical reaction tank, and the second cavity 6 constitutes a clear water tank.

[0040] The above is the core content of the present invention. The filter system 3 is arranged on the inner shell 2, so that the filter system 3 and the inner shell 2 form an integrated structure, and...

Embodiment 2

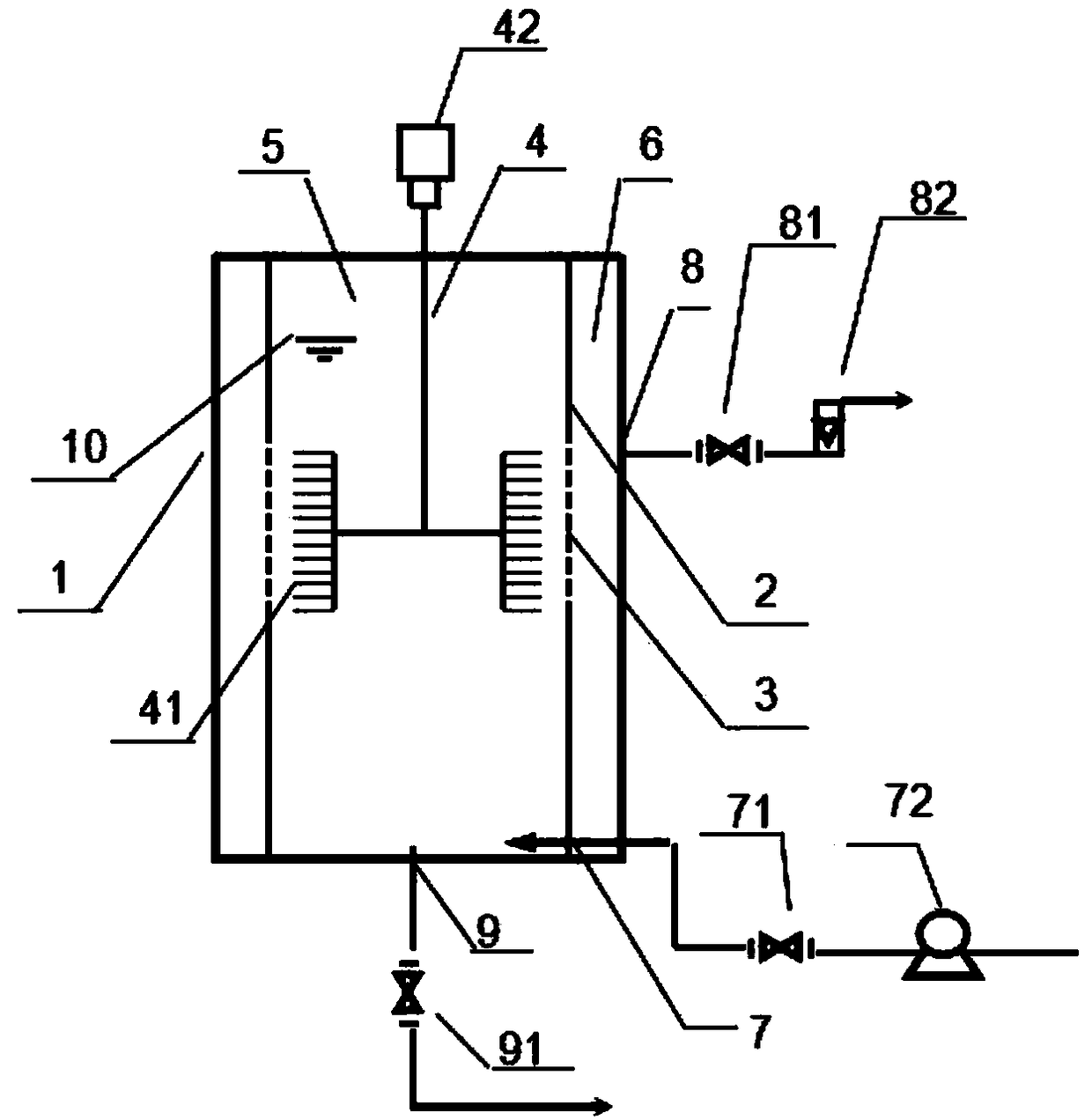

[0053] figure 2 The shown integrated membrane bioreaction system (anaerobic) is characterized in that it includes an outer shell 1, an inner shell 2, a filtration system 3 and a cleaning device 4, the inner shell 2 is arranged inside the outer shell 1, and the inner shell 2 The hollow part forms the first cavity 5, and the second cavity 6 is formed between the inner shell 2 and the outer shell 1; the filter system 3 is arranged on the inner shell 2, and the inner shell 2 and the outer shell 1 pass through the filter system 3 The cleaning device 4 is arranged inside the first cavity 5 , and the cleaning device 4 is used for cleaning the filter system 3 . The first cavity 5 is a membrane biochemical reaction tank, and the second cavity 6 constitutes a clear water tank.

[0054] The above is the core content of the present invention. The filter system 3 is arranged on the inner shell 2, so that the filter system 3 and the inner shell 2 form an integrated structure, and the prim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com