Low-dielectric constant low-loss low-temperature co-fired ceramic material and preparation method thereof

A technology of low-temperature co-fired ceramics and low dielectric constant, applied in the field of low-temperature co-fired ceramics, can solve the problems of deteriorating material performance and process applicability, difficult to scale up production, difficult to grind and fine process, etc., to avoid high-temperature smelting glass to assist firing agent, beneficial to industrial production, and the effect of excellent insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The invention provides a method for preparing a low-dielectric constant and low-loss low-temperature co-fired ceramic material, comprising:

[0041] Step 1. Weigh 10-40 parts by mass of Al 2 o 3 , 0 to 40 parts by mass of SiO 2 , 0-60 parts by mass of powder A, 0-60 parts by mass of powder B, 8-30 parts by mass of powder C and 0-0.5 parts by mass of toner, the toner is Co 3 o 4 , MnO 2 、Cr 2 o 3 and SrCO 3 One or more of them, the coloring material can be added or not according to the needs, put the prepared powder into the ball mill for mixing, the ball / material mass ratio is 2-10, and the grinding ball is zirconia ball , the ball milling time is 4 to 8 hours, the speed is 250 to 450 rpm, the powder after ball milling is put into an oven and dried at 120°C, and the powder is ground and passed through a 100-mesh sieve;

[0042] Step 2, take 2 grams of the above powder, add 15-20 drops of PVA aqueous solution (6.5wt% polyvinyl alcohol) to bond and granulate, and ...

Embodiment

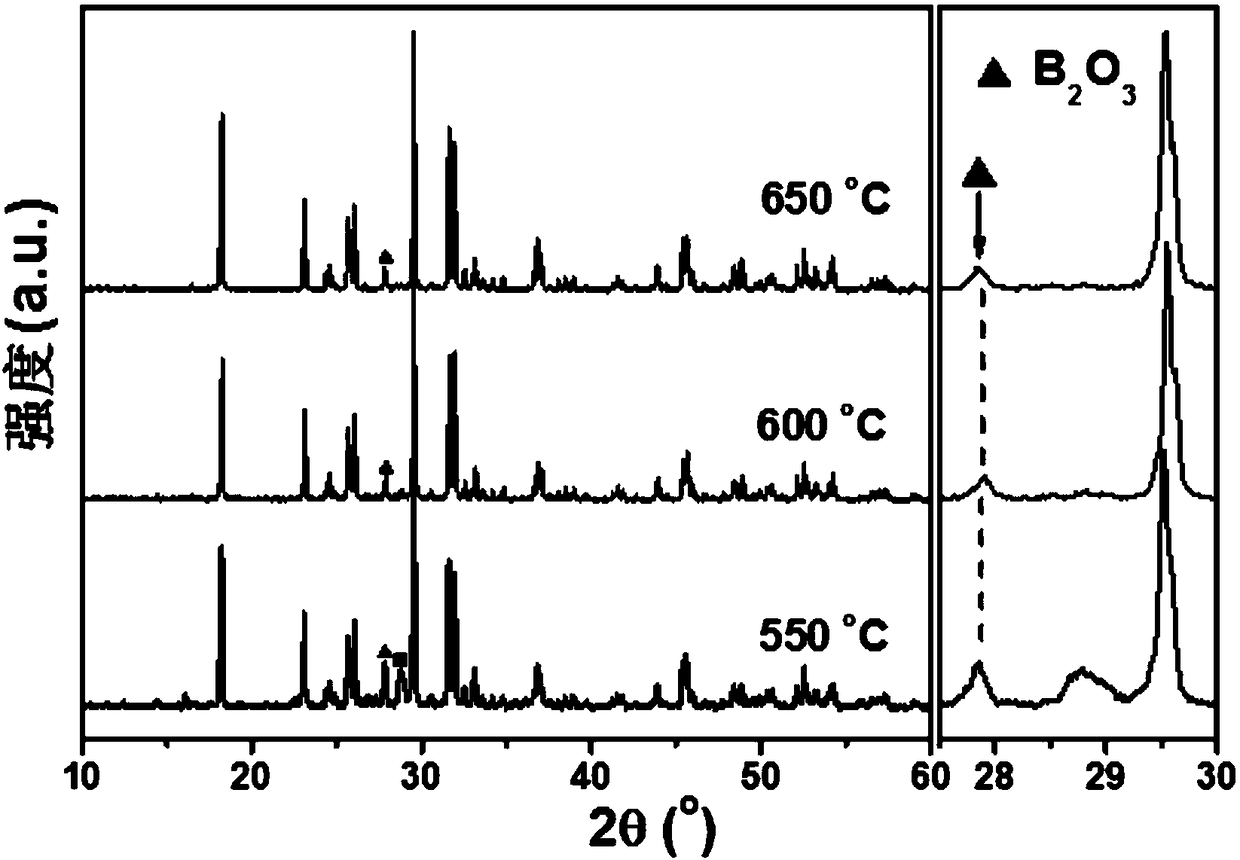

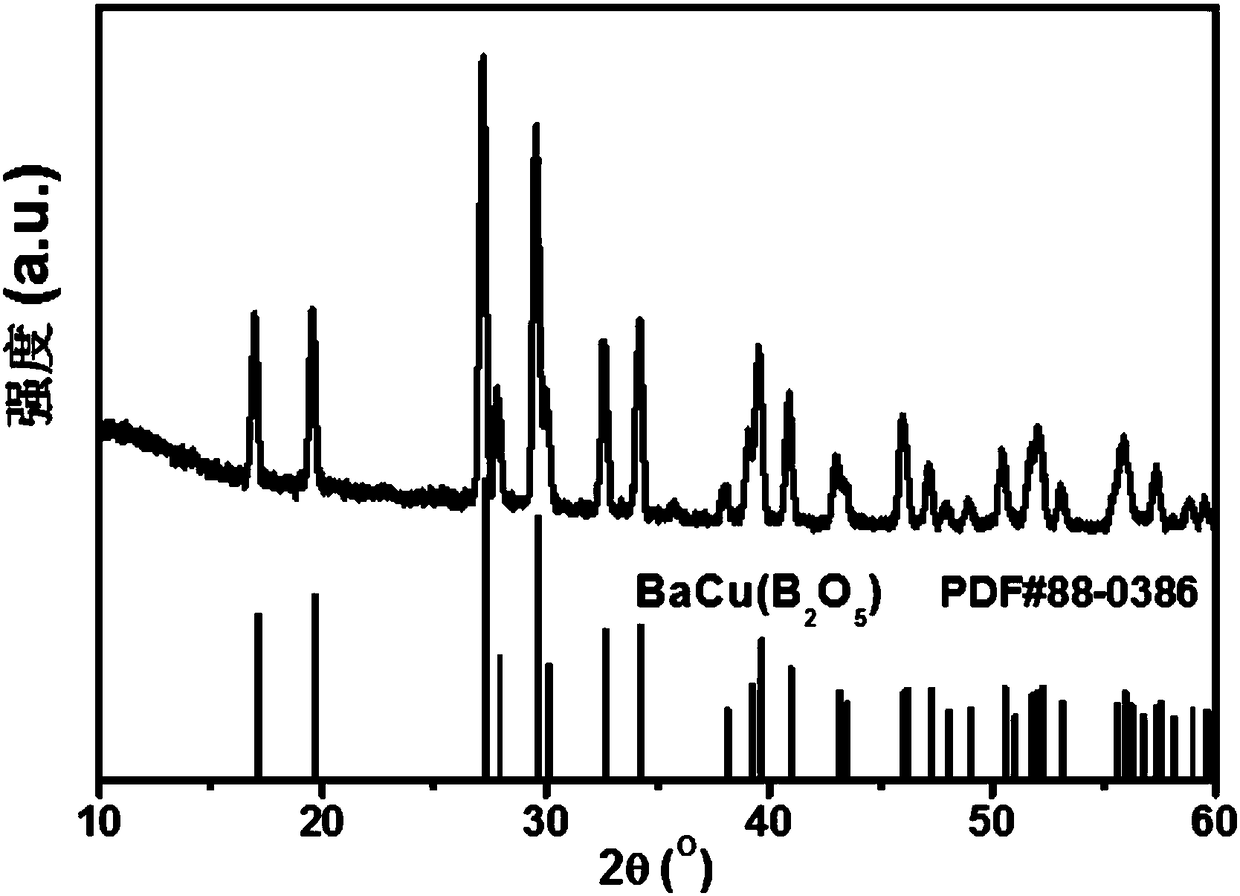

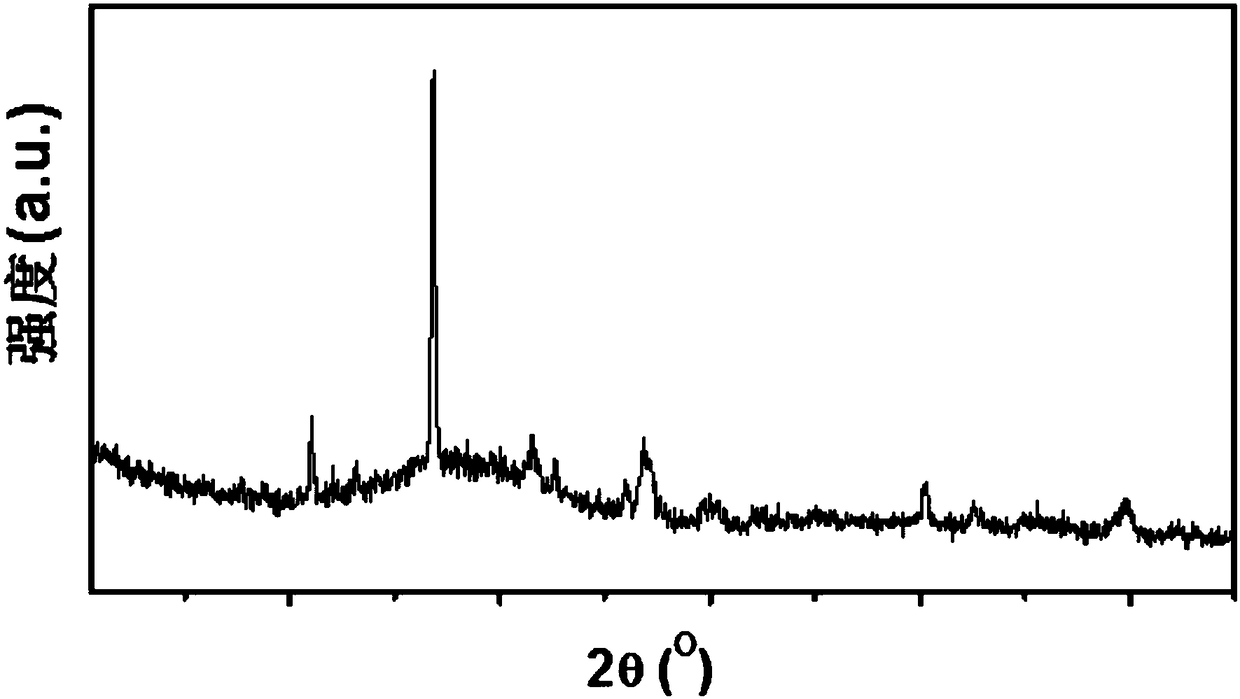

[0054] The present invention calculates the formula according to the number of parts by mass, and specific examples are shown in Table 1. Use analytically pure Al 2 o 3 , SiO 2 and solid-phase synthesized powders A, B and C, where Al 2 o 3 The mass parts are 10-40, SiO 2 The mass parts of powder A are 0-40, the powder A is calcined body, its mass parts are 0-60, and the components of powder A are 40-70 mass parts of Bi 2 o 3 , 10-30 parts by mass of ZnO, 15-45 parts by mass of H 3 BO 3 ; When in use, it can be in Bi 2 o 3 , ZnO, H 3 BO 3 Prepare powder A within the mass range, the preferred component of powder A in table 1 is the Bi of 60 mass parts 2 o 3 , 20 parts by mass of ZnO, 20 parts by mass of H 3 BO 3 , Bi of other components 2 o 3 , ZnO, H 3 BO 3 All can meet the requirements, so I will not elaborate here; powder B is a calcined body, its mass part is 0-60, and its components are BaO precursor, CuO and H in a molar ratio of 1:1:2. 3 BO 3 ; Powder...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com