Water-based suede slurry, and method and application of wet processing suede

A suede, water-based technology, used in transportation and packaging, flexible coverings, textiles and papermaking, etc., can solve the problems of electronic microfiber leather that is not full, environmentally friendly, and low in softness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] Preparation of aqueous polyurethane dispersion A:

[0060] 223g WANOL C2056 (polyether polyol), 44g TDI 80 (toluene diisocyanate), 5g 1,4-butanediol (diol chain extender), 5g dimethylol propionic acid (hydrophilic chain extender) and 50 g of acetone (solvent) were added into a 1 L four-neck round-bottomed flask equipped with a nitrogen inlet and outlet, and the mixture was stirred at 75° C. until NCO reached 1.3 wt%. Cool down to 40-45°C, add 231g of acetone and 3.8g of triethylamine to neutralize for about 5 minutes, then disperse the mixture by adding 420g of water, add 4g of isophoronediamine (small molecule amine chain extender) after the dispersion and continue stirring Chain extension for 10 minutes. After separation of the acetone by distillation, a solvent-free dispersion was obtained which had a solids content of 43% by weight, an average particle size of 220 nm and a pH value of 8.4.

[0061] Preparation of Aqueous Polyurethane Dispersion B:

[0062]Add 400...

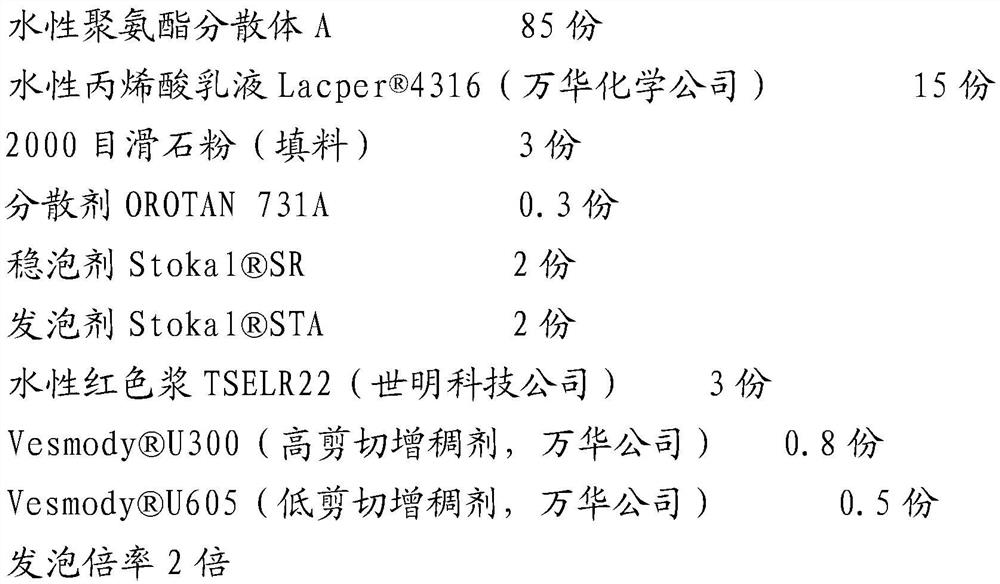

Embodiment 1

[0070] The "parts" mentioned in the formulas of the embodiments all refer to parts by mass, and the same is true in other embodiments, so no more details are given.

[0071]

[0072] In the present embodiment, take water-based polyurethane dispersion A mass part and 4316, dispersant ( 731A), the rotating speed of 600 rev / min stirred for 10 minutes, then added talcum powder (mesh number 2000), the rotating speed of 800 rev / min stirred for 15 minutes, added whipping agent ( STA), foam stabilizer ( SR), water-based red paste (Shiming Technology TSELR22), thickener (VesmodyU300, water-based polyurethane thickener), thickener (VesmodyU605, water-based polyurethane thickener), stirred for 15 minutes at a speed of 1000 rpm, Prepare a slurry with a viscosity of about 4000cp, using a mechanical foaming machine (Italy GEMAT foaming machine MICROMIX / 14) with a foaming ratio of 2 times.

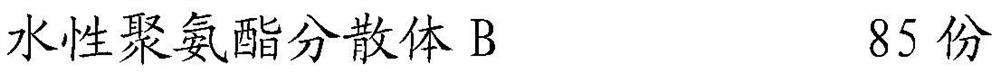

Embodiment 2

[0074]

[0075]

[0076] In the present embodiment, get aqueous polyurethane dispersion B and 4316, dispersant ( 731A), the rotating speed of 600 rev / min stirred for 10 minutes, then added talcum powder (mesh number 2000), the rotating speed of 800 rev / min stirred for 15 minutes, added whipping agent ( STA), foam stabilizer ( SR), water-based red paste (Shiming Technology TSELR22), thickener (VesmodyU300, water-based polyurethane thickener), thickener (VesmodyU605, water-based polyurethane thickener), stirred for 15 minutes at a speed of 1000 rpm, Prepare a slurry with a viscosity of about 4000cp; use a mechanical foaming machine to double the foaming ratio.

PUM

| Property | Measurement | Unit |

|---|---|---|

| number average molecular weight | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com