Y-Fe-based rare-earth hydrogen storage material and preparation method thereof

A hydrogen storage material and rare earth technology, which is applied in the field of Y-Fe-based rare earth hydrogen storage material and its preparation, can solve the problems of limitation and large price fluctuation of Ni, and achieves fast hydrogen absorption rate, small price fluctuation and low activation temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

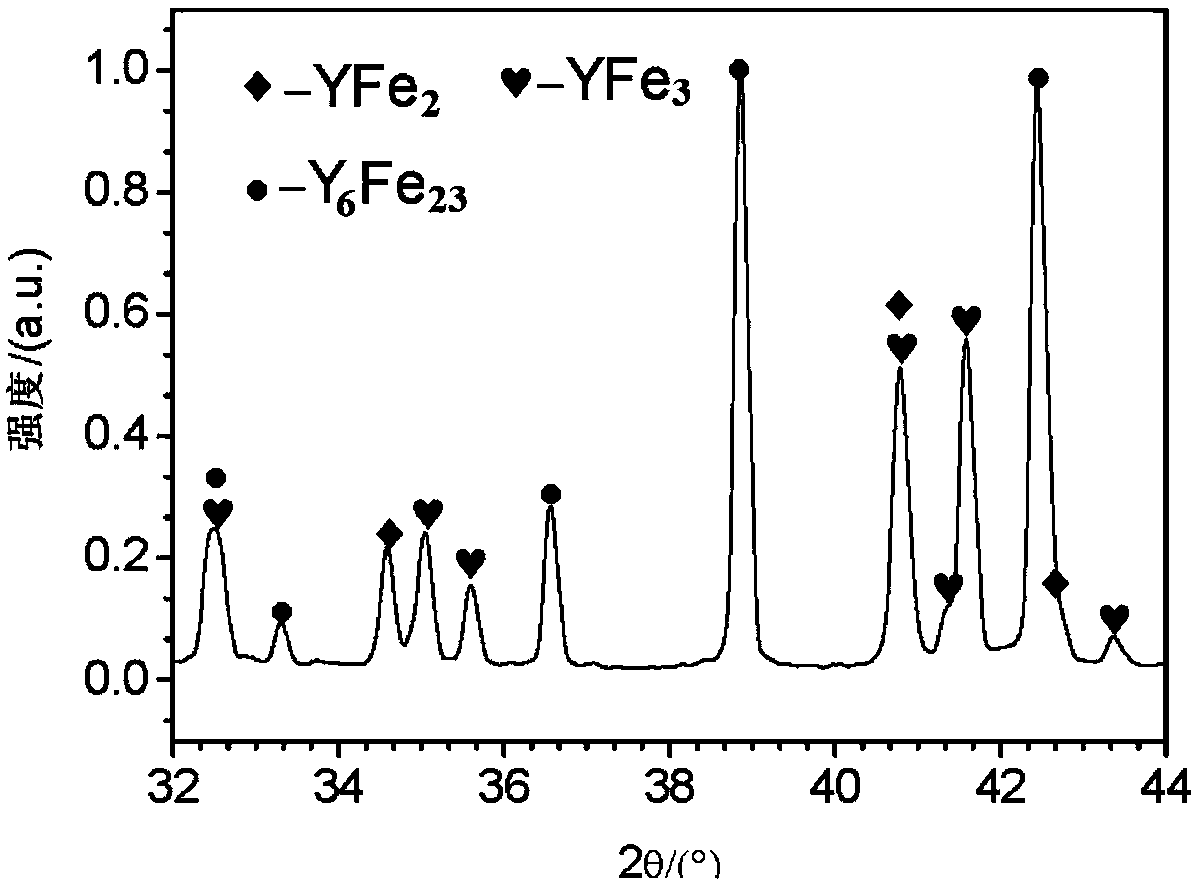

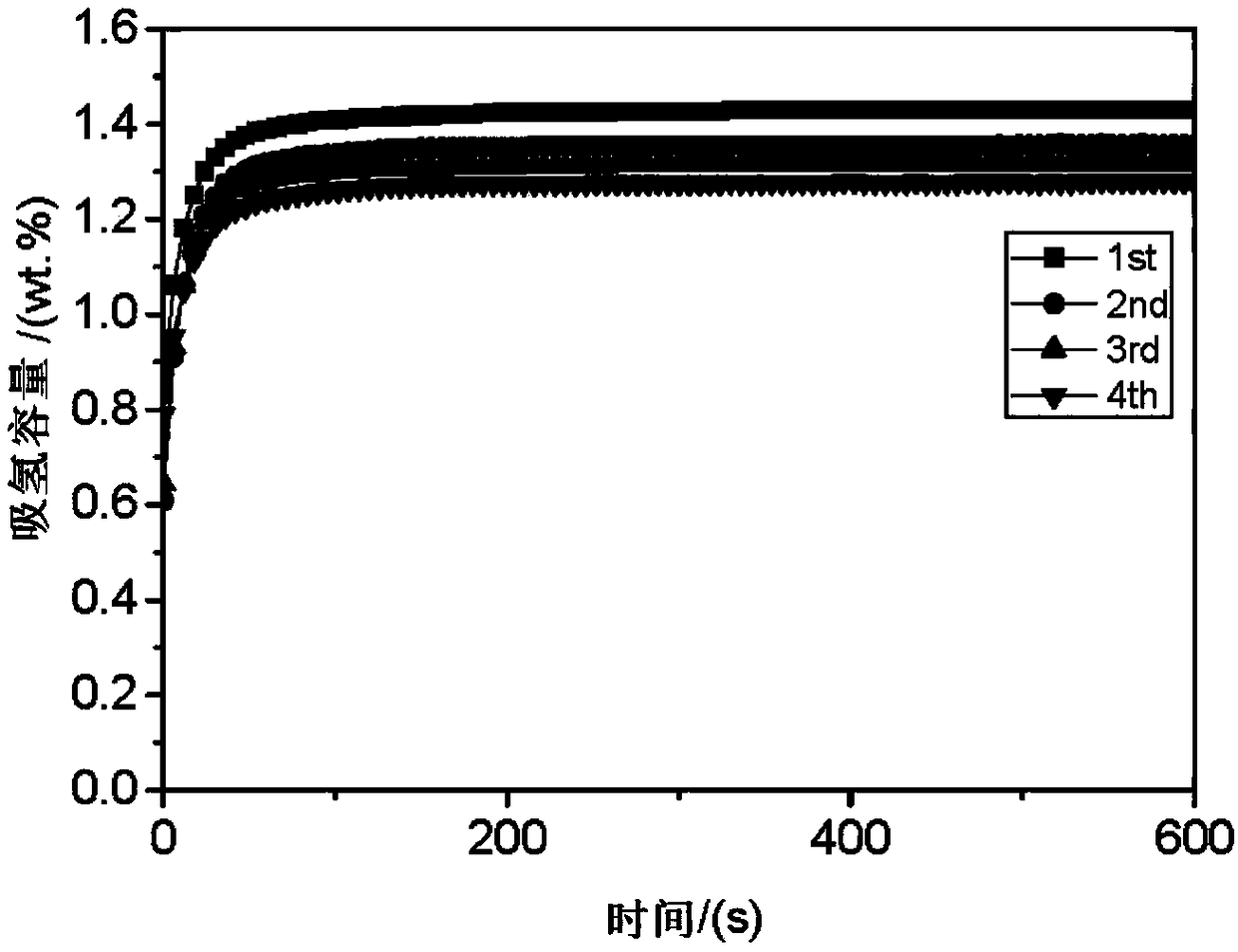

[0029] The raw materials are Y (purity ≥ 99.6%), Fe (purity ≥ 99.5%), and the chemical composition is YFe 3 . The alloy adopts a medium-vacuum medium-frequency induction furnace. When the melting temperature reaches 1600-1800°C, the alloy is completely melted and then refined for 10-30 minutes. Water-cooled mold is used for pouring and rapid solidification to obtain ingots. The pouring temperature is 1550-1750°C; the ingots are broken under the protection of argon atmosphere, and the alloy particles smaller than 30-400 meshes are screened; the alloy particles are heated to 300°C under vacuum conditions. Activate for 60 minutes, then cool to 25°C for hydrogen absorption. The experimental results show that the alloy has a multiphase structure, such as figure 1 shown. The experimental results show that the alloy is a multiphase structure, containing AB 2 (MgCu 2 type), AB 3 (PuNi 3 type) and A 6 B 23 (Th 6 mn 23 type) structure, the main phase structure is A 6 B 23 ,...

Embodiment 2

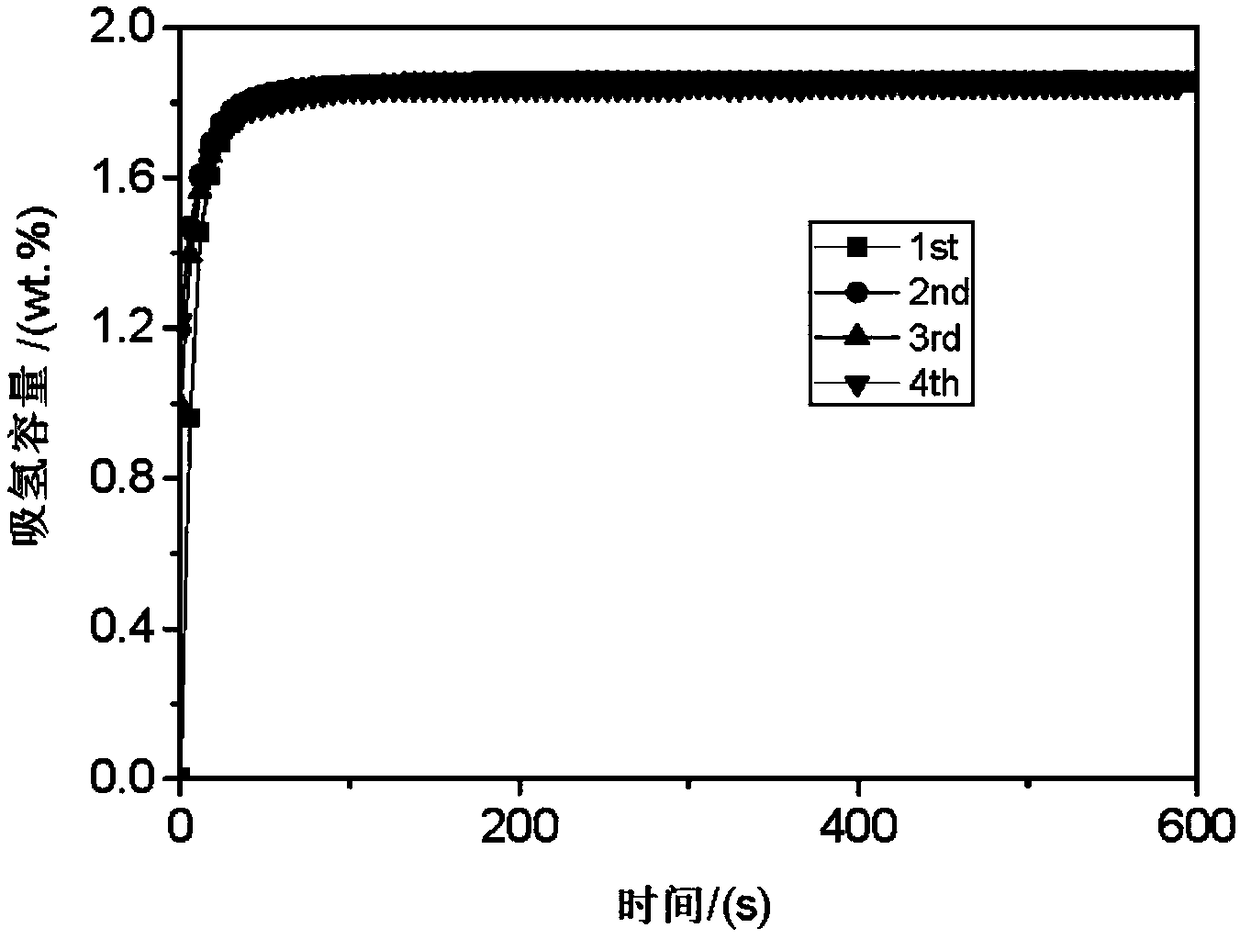

[0031] The raw materials are Y (purity ≥ 99.6%), Fe (purity ≥ 99.5%), and the chemical composition is YFe 3 . The alloy adopts a medium-vacuum medium-frequency induction furnace. When the melting temperature reaches 1600-1800°C, the alloy is completely melted and then refined for 10-30 minutes. Water-cooled mold casting is used to solidify quickly to obtain ingots. The pouring temperature is 1550-1750°C; the ingots are annealed under the protection of argon atmosphere, the annealing temperature is 1100°C, and the annealing time is 72 hours; the alloy is broken under the protection of argon atmosphere. Alloy particles smaller than 30-400 mesh are screened; the alloy particles are heated to 300°C under vacuum conditions, activated for 60 minutes, and then cooled to 25°C for hydrogen absorption. The hydrogen absorption kinetics test results of the alloy are as follows: image 3 shown. The experimental results show that the alloy is a multiphase structure, containing AB 2 (MgC...

Embodiment 3

[0034] The raw materials are Y (purity ≥ 99.6%), Sm (purity ≥ 99.0%), Fe (purity ≥ 99.5%), and the chemical composition is Y 0.65 Ce 0.35 Fe 3 . The alloy adopts a medium-vacuum medium-frequency induction furnace. When the melting temperature reaches 1600-1800°C, the alloy is completely melted and then refined for 10-30 minutes. Casting in a water-cooled mold, rapid solidification to obtain ingots, the pouring temperature is 1550-1750°C; the ingots are annealed under the protection of argon atmosphere, the annealing temperature is 1200°C, and the annealing time is 108 hours; the ingots are broken under the protection of argon atmosphere , screened to obtain alloy particles smaller than 30-400 mesh; the alloy particles were heated to 250°C under vacuum conditions, activated for 60 minutes, and then cooled to 25°C for hydrogen absorption. The experimental results show that the alloy is a multiphase structure, containing AB 2 (MgCu 2 type), AB 3 (PuNi3 type) and A 6 B 23 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com