Optical fiber FP (Fabry-Perot) gas pressure sensor with optical vernier effect as well as preparation method thereof

A technology of air pressure sensor and vernier effect, which is applied to fluid pressure measurement, instruments, and measurement of fluid pressure using optical methods. It can solve the problems of expensive femtosecond lasers, expensive equipment and instruments, and low air pressure sensitivity, and achieve great freedom. Effects of spectral range, simple preparation method, and large measurement range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with accompanying drawing, the present invention is described in further detail:

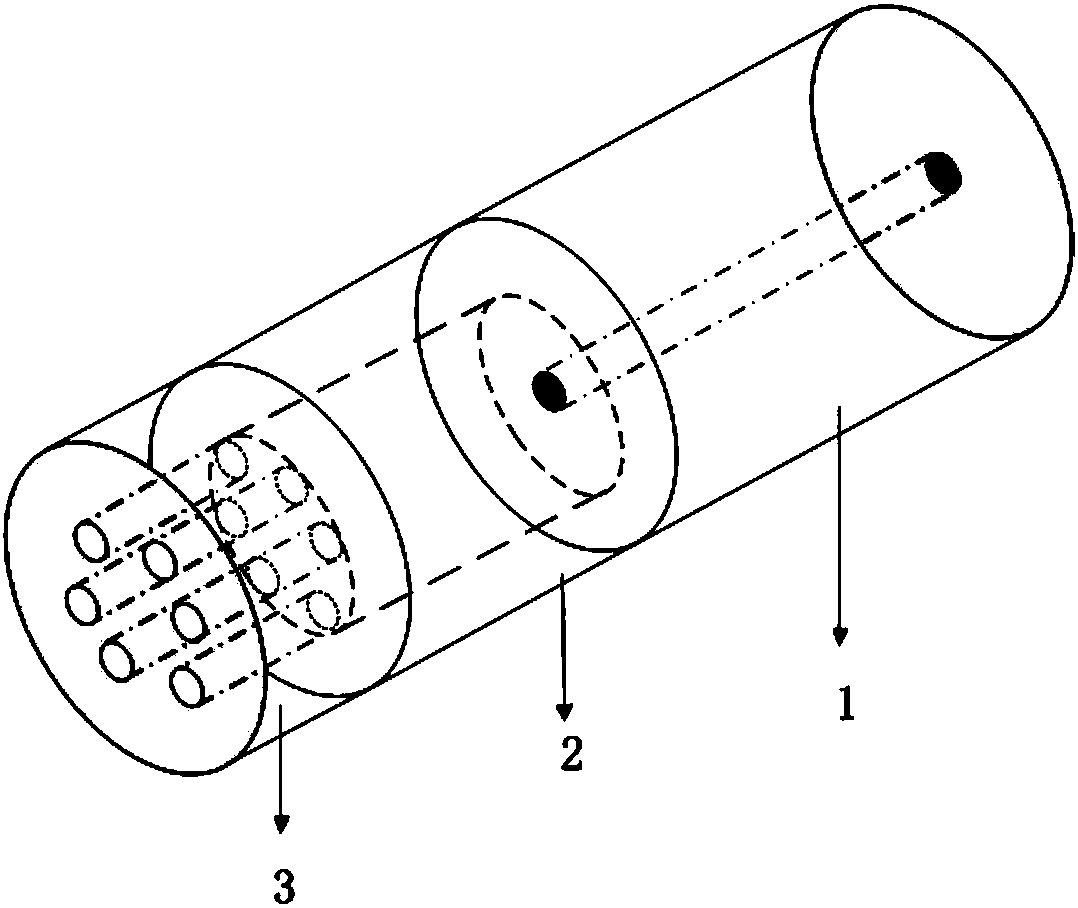

[0034] figure 1 It is a structural schematic diagram of an embodiment of the optical fiber FP air pressure sensor with optical vernier effect of the present invention. This embodiment includes a single-mode optical fiber 1 , a quartz capillary 2 , and a photonic crystal optical fiber 3 . The quartz capillary 2, the photonic crystal fiber 3 and the single-mode fiber 1 have the same outer diameter of 125 microns, and the inner diameter of the quartz capillary 2 is 40 microns. The cladding of photonic crystal fiber 3 is composed of six air holes arranged in a triangle, the diameter of the air hole is 3.4 microns, and the core is formed by missing one air hole, and the diameter of the core is 10 microns.

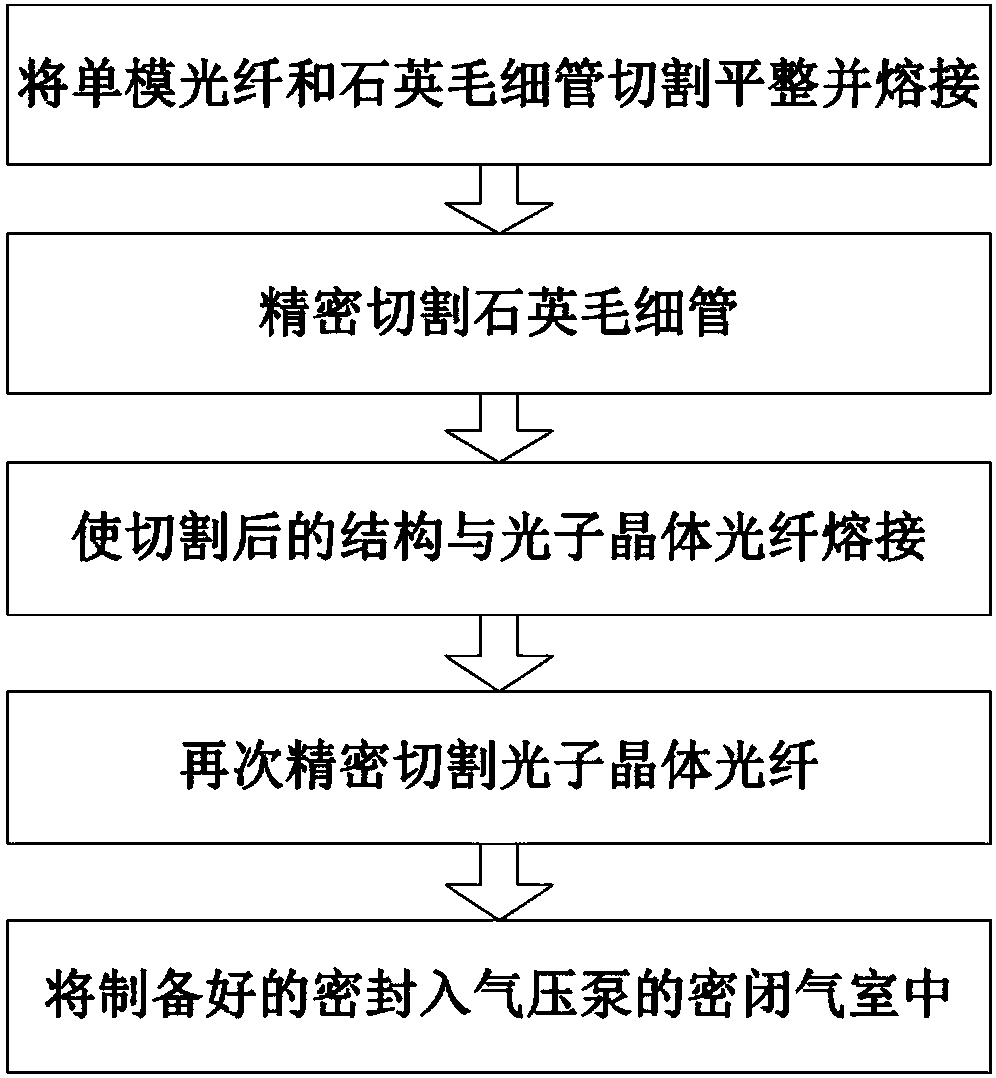

[0035] figure 2 It is a flowchart of an embodiment of the preparation method of the optical fiber FP air pressure sensor with optical vernier effect of the present ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com