An ultrasonic phased array based method for extracting three-dimensional parameters of inner defects of a component

An ultrasonic phased array and internal defect technology, which is applied in the analysis of solids using sonic/ultrasonic/infrasonic waves, material analysis using sonic/ultrasonic/infrasonic waves, and processing response signals of detection. , lack of reliability and other problems, to achieve the effect of low detection cost, simplified calculation steps, and intuitive imaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

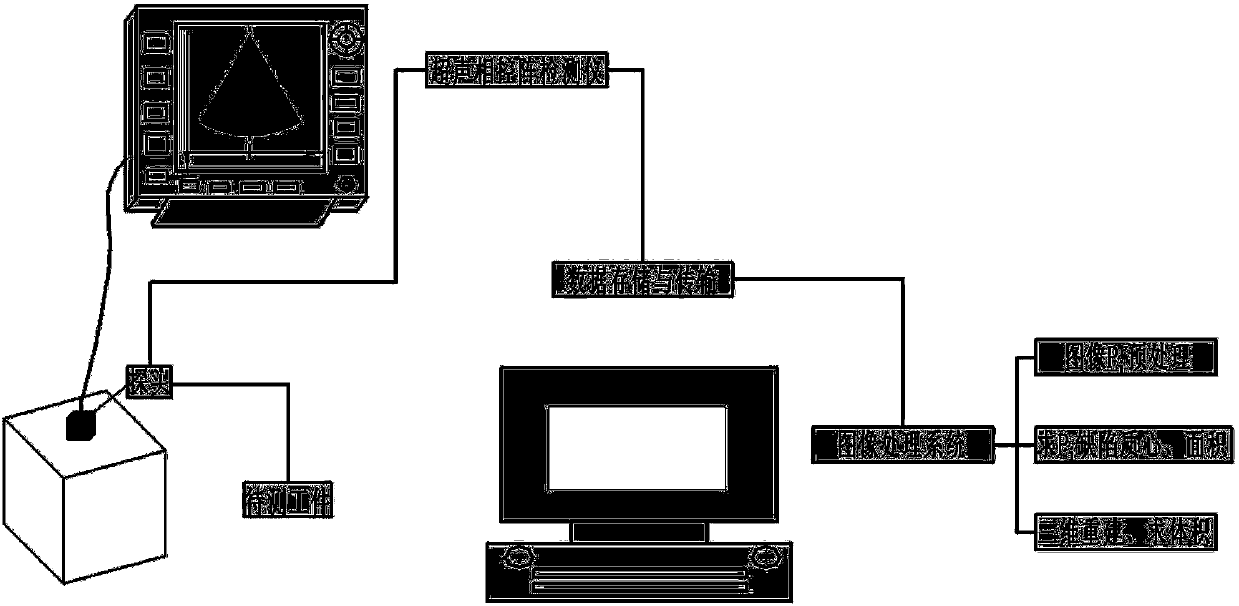

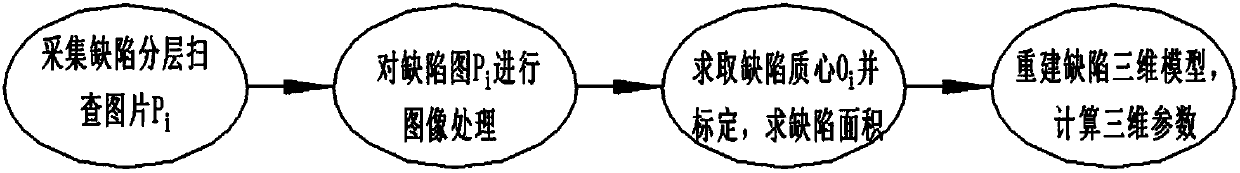

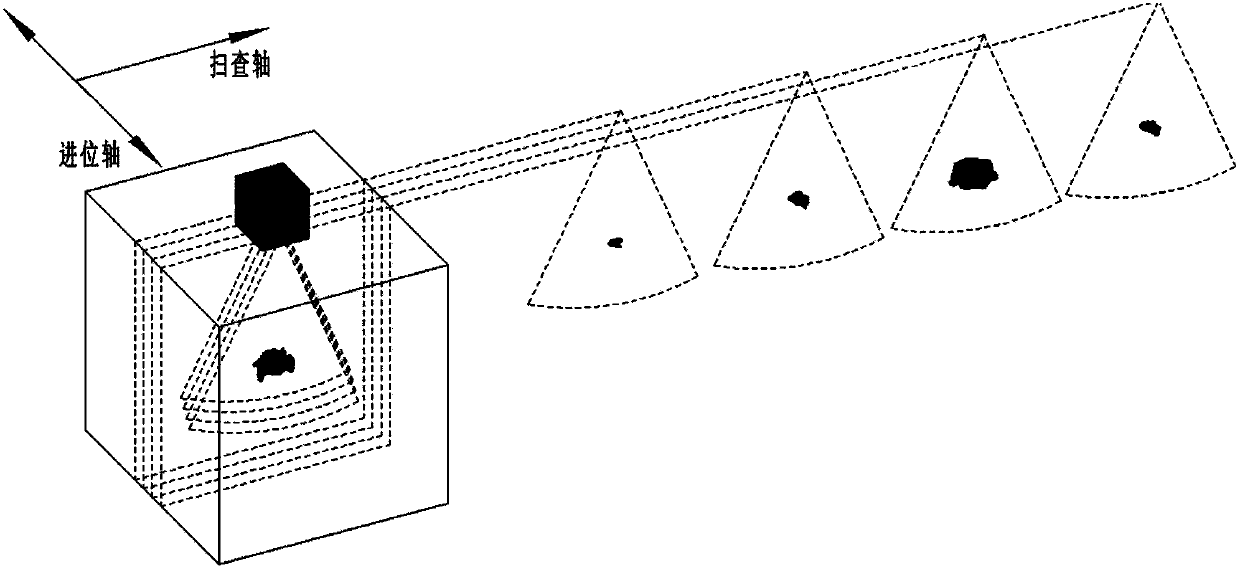

[0043] The invention provides a method for extracting three-dimensional parameters of internal defects based on ultrasonic phased array technology, which fully utilizes and brings into play the characteristics of multi-angle, dynamic focusing, flexibility, and intuitive imaging of ultrasonic phased array equipment, and utilizes the lateral movement of the probe and the Carry forward vertically to realize the positioning and scanning of internal defects of parts, and mainly collect defect pictures and data information with S display to achieve the purpose of layered scanning and imaging of defects; then filter, noise reduction, edge extraction, etc. for the collected pictures Image processing technology; then obtain the centroid position of the defect in each picture, and calibrate and calculate the area of the defect; use the area equivalent principle to perform equivalent processing on all the pictures, and then arrange them in order to realize the three-dimensional reconstru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com