Method of directly detecting content of mercury in solid rubber by means of mercury detector

A solid rubber and rubber technology, applied in the direction of measuring devices, test sample preparation, instruments, etc., can solve the problems of cumbersome and time-consuming atomic fluorescence spectrometry steps, increased time and labor costs, environmental and laboratory personnel health hazards, etc. , to achieve the effects of reducing time and labor costs, fast detection speed, and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The first step is to take about 100g samples from different parts of the solid rubber sample and mix them with an open rubber mixer, and then cut the samples to small fragments less than 2.0mm×2.0mm in size to ensure their representativeness.

[0030] In the second step, before the sample test, run the instrument dry to perform a method blank test until the absorbance value is less than 0.003 to remove the mercury residue in the instrument.

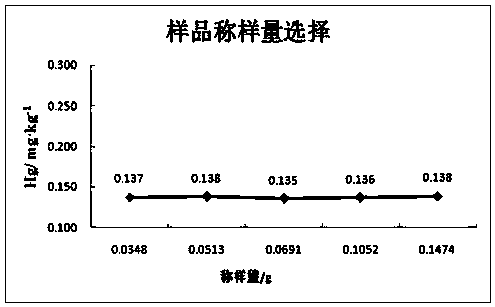

[0031] The third step is to weigh 0.03g of the rubber sample after mixing, accurate to 0.1mg, and evenly spread it in the sample boat, place the sample boat in the automatic sample tray, in the computer software system connected to the mercury meter Enter the sample weight;

[0032] Set and select the working conditions of the instrument: drying temperature 350 ℃, time 30 s, purge time 30 s, analysis time 12 s, reading time 24 s, oxygen pressure 0.45Mpa;

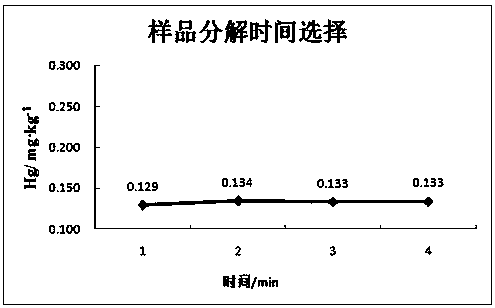

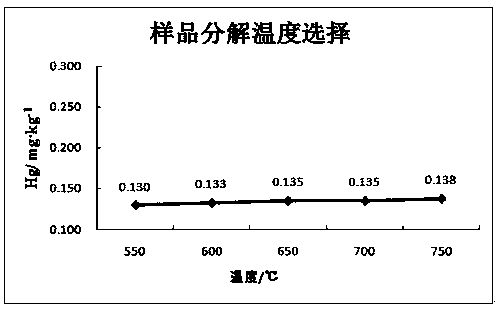

[0033] Set the decomposition conditions of the sample: the decomposition time of the...

Embodiment 2

[0036] The first step is to take about 100g samples from different parts of the solid rubber sample and mix them with an open rubber mixer, and then cut the samples to small fragments less than 2.0mm×2.0mm in size to ensure their representativeness.

[0037] In the second step, before the sample test, run the instrument dry to perform a method blank test until the absorbance value is less than 0.003 to remove the mercury residue in the instrument.

[0038] The third step is to weigh 0.05g of the rubber sample after mixing, accurate to 0.1mg, and spread it evenly in the sample boat, place the sample boat in the automatic sample tray, in the computer software system connected to the mercury meter Enter the sample weight;

[0039] Set and select the working conditions of the instrument: drying temperature 350 ℃, time 30 s, purge time 30 s, analysis time 12 s, reading time 24 s, oxygen pressure 0.45Mpa;

[0040] Set the decomposition conditions of the sample: the decomposition time of the...

Embodiment 3

[0043] Weigh 0.07 g of the rubber sample after mixing, and other conditions and steps are the same as in Example 1.

[0044] After the experiment, the software system gave the mercury content determination result of 0.135 mg / kg according to the standard curve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com