Preparation method of twenty-six-side CsPbX3 perovskite nanocrystalline

A technology of hexahedron and perovskite, applied in nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the unfavorable growth process of perovskite nanocrystals, uneven morphology, etc. problems, to achieve the effects of controllable components, easy adjustment of product size, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] First, a cesium oleate solution is prepared. Take 2mmol (0.648g) of cesium carbonate powder, 10mmol (3.35mL) of OA (oleic acid) and 6.65mL of ODE (octadecene) and mix them, heat to 150°C under nitrogen protection to dissolve cesium carbonate, cool to 100 ℃, prepared into 0.2M cesium oleate solution, which was light yellow transparent solution.

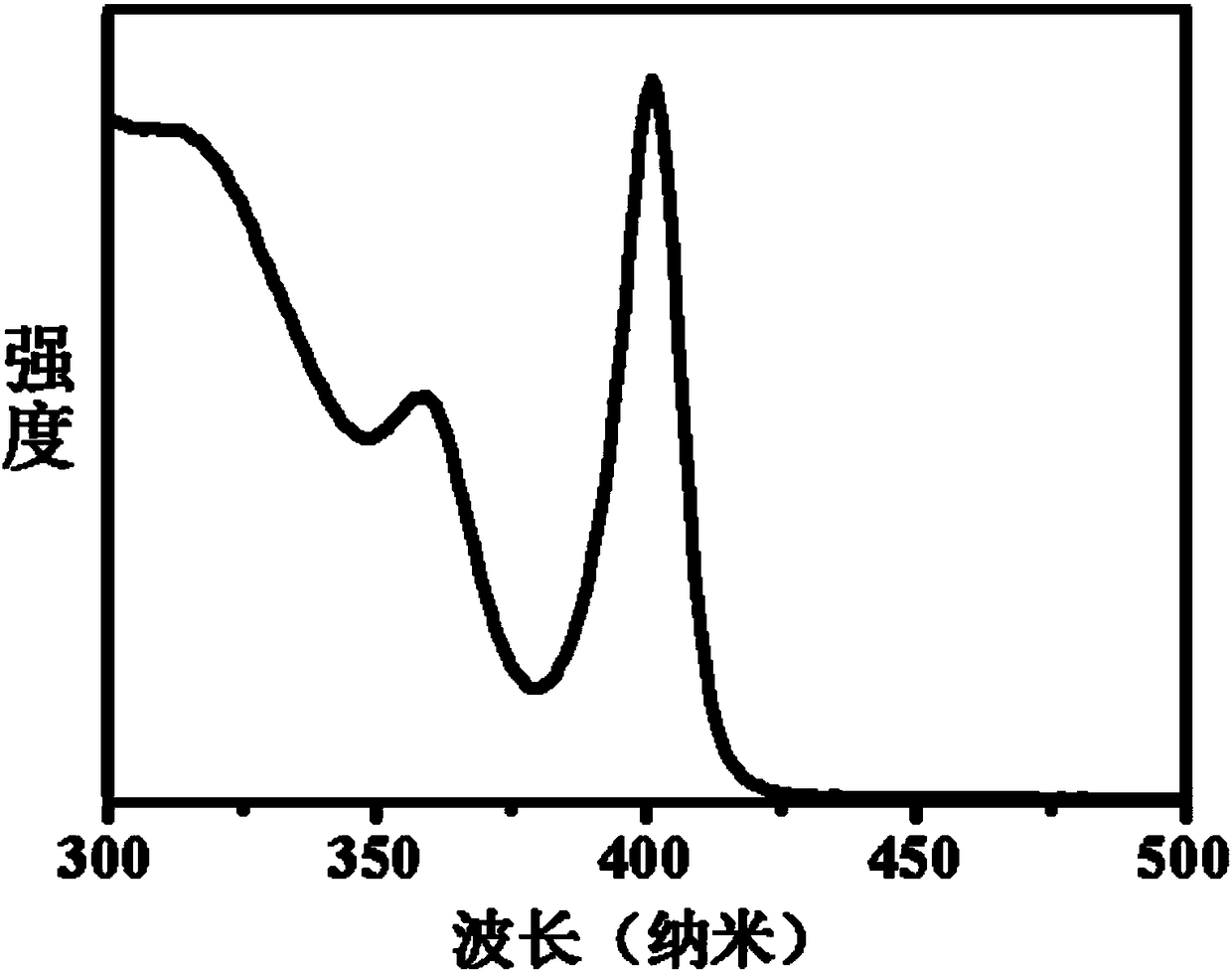

[0029] Then take 0.2mmol of lead bromide solid powder, 0.6mL of oleylamine, 0.6mL of oleic acid and 2.8mL of octadecene into the three-necked flask, vacuumize at 50°C for 30 minutes, fill with nitrogen protection, and then heat up to 150°C , after the lead bromide is dissolved, lower it to room temperature 25°C, and then inject 0.2mL of 0.2M cesium oleate octadecene solution, and react to obtain CsPbBr with an absorption peak at 402nm 3 Perovskite nanocrystalline seeds. Its absorption spectrum is shown in figure 1 .

Embodiment 2

[0031] The 0.04mmol of CsPbBr prepared in Example 1 3 The perovskite nanocrystal seeds were centrifuged, precipitated and dispersed into 4 mL of octadecene.

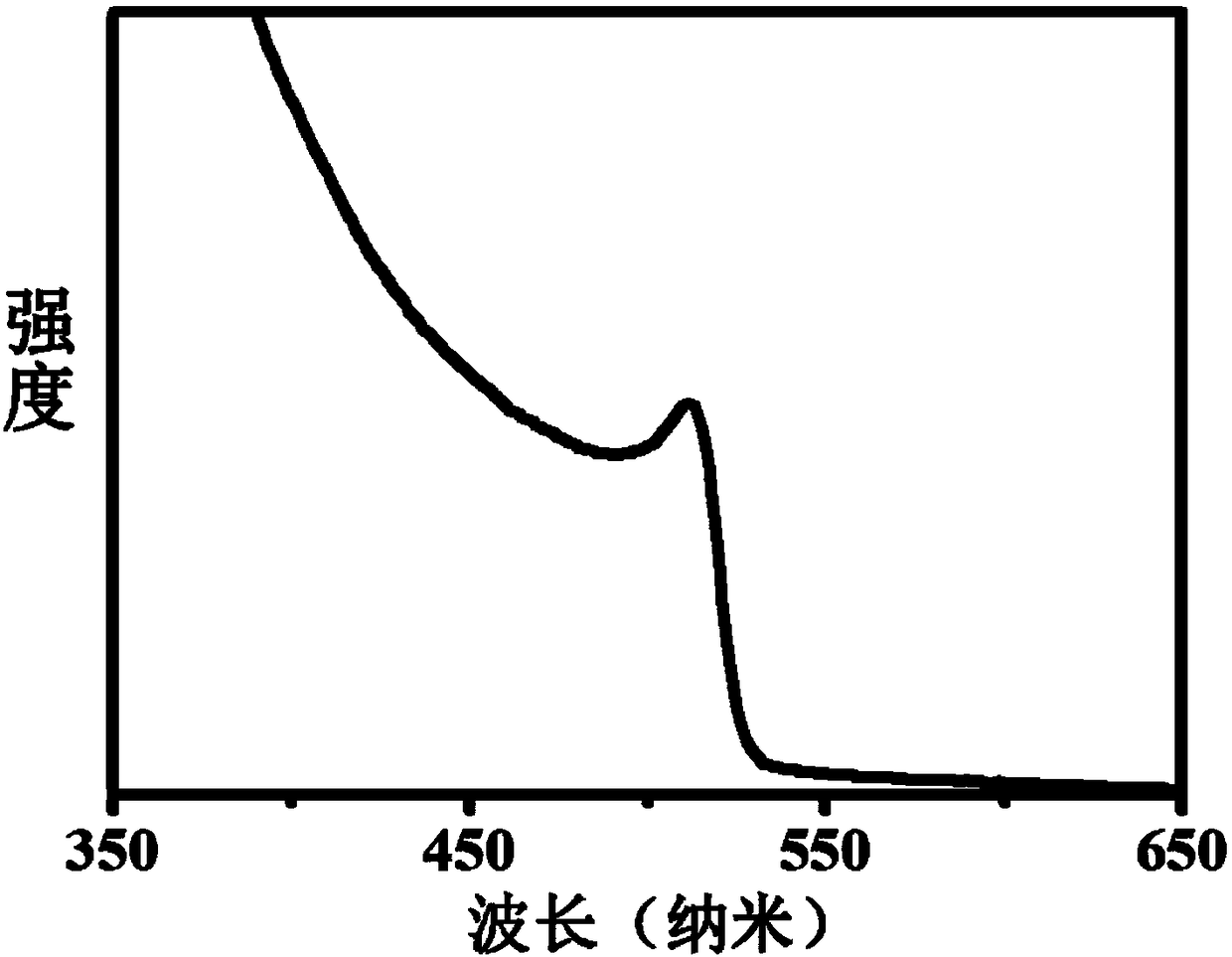

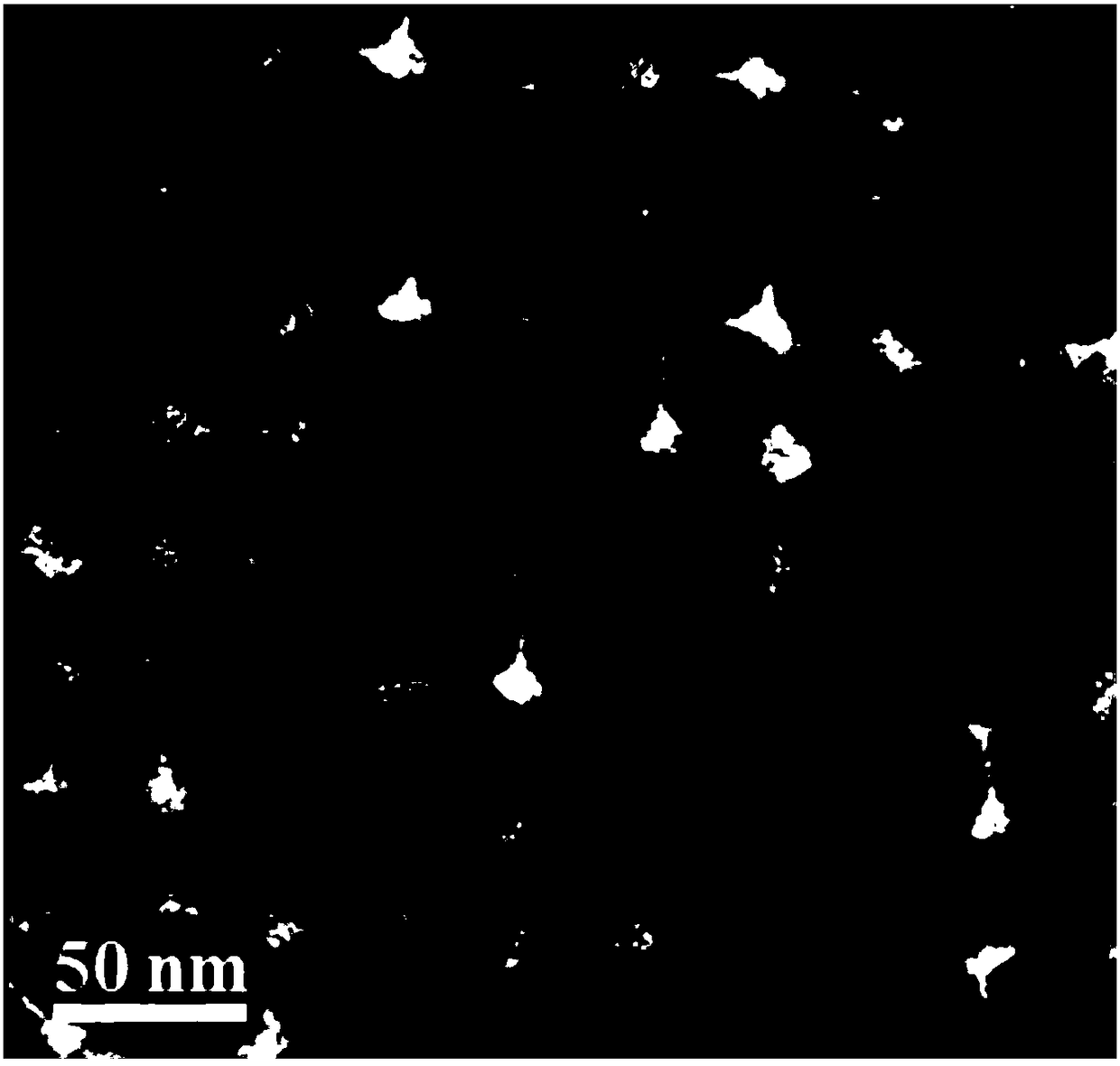

[0032] Take the above 4mL CsPbBr 3The octadecene solution of perovskite nanocrystal seeds was added to a three-neck flask, filled with nitrogen for protection, added 0.02 mmol of stearyl phosphoric acid, and then heated to 205 ° C, and the reaction obtained CsPbBr with an absorption peak at 512 nm 3 Perovskite nanocrystals with a particle size of 28nm. Its absorption spectrum is shown in Figure 4 , see its electron micrograph Figure 5 .

Embodiment 3

[0034] The 0.04mmol of CsPbBr prepared in Example 1 3 The perovskite nanocrystal seeds were centrifuged, precipitated and dispersed into 4 mL of octadecene.

[0035] Take the above 4mL CsPbBr 3 The octadecene solution of the perovskite nanocrystal seeds was added to the three-neck flask, filled with nitrogen for protection, added 0.02 mmol of octadecyl phosphoric acid, and then heated to 215 ° C, and the reaction obtained CsPbBr with an absorption peak at 514 nm 3 Perovskite nanocrystals with a particle size of 36nm. Its absorption spectrum is shown in Figure 6 , see its electron micrograph Figure 7 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com