Preparation method of hollow sandwich-shaped iron-based negative electrode material

A sandwich-type, negative electrode material technology, applied in the direction of battery electrodes, electrical components, electrochemical generators, etc., can solve the problems of limited performance improvement and limited improvement, and achieve low cost, increase electrical conductivity, and facilitate conduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

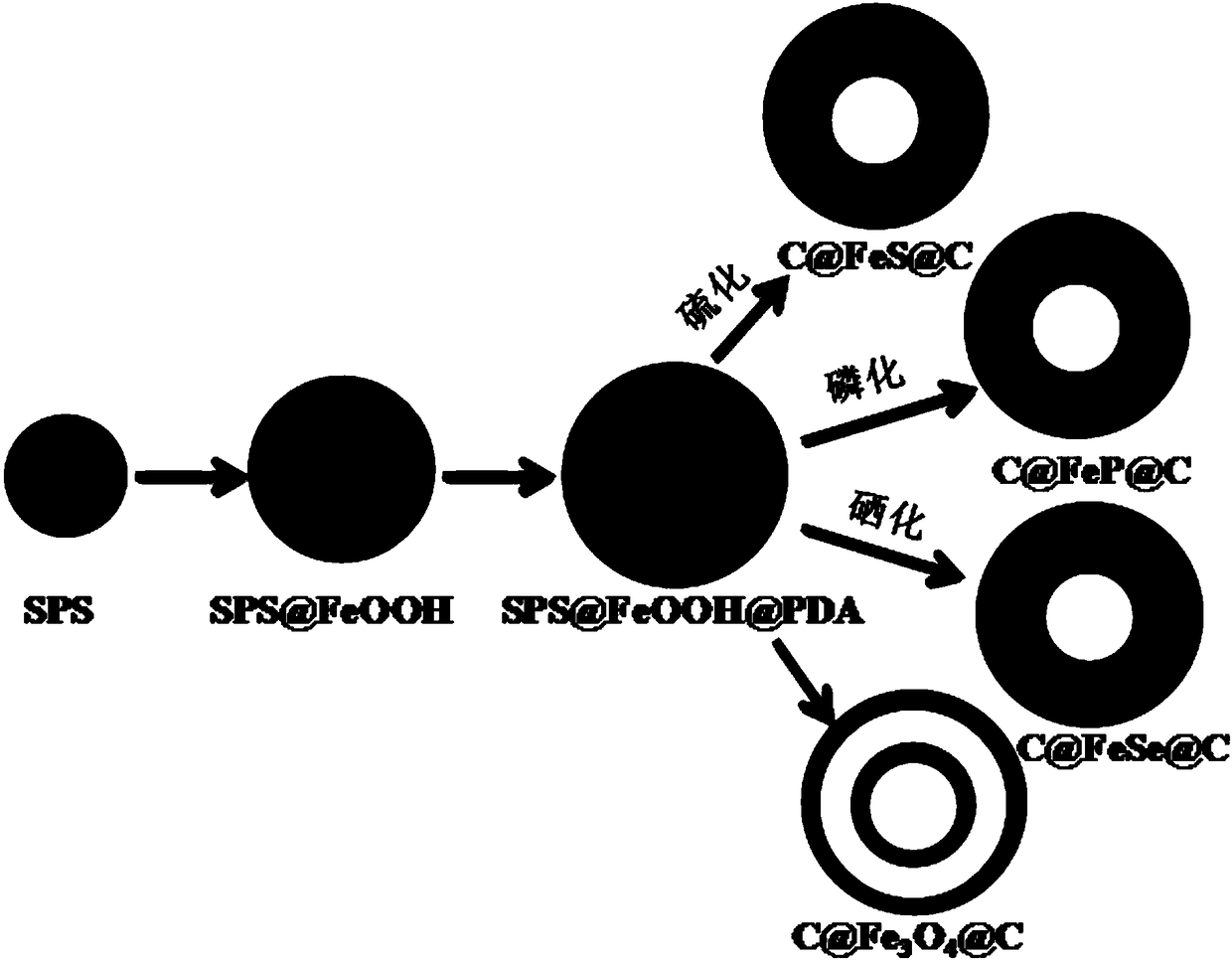

[0024] The preparation method of the hollow sandwich iron-based negative electrode material of the present invention comprises the following steps: (a) dispersing the sulfonated polymer microspheres or fibers into the Fe-containing 3+ in the aqueous solution, heating and drying to obtain the first core-shell complex; (b) dispersing the first core-shell complex (ie sulfonated polymer @FeOOH) in a buffered aqueous solution containing trishydroxymethylaminomethane , add dopamine (DA) under stirring conditions and make it polymerize on the surface of the first core-shell complex to obtain a sandwich-type polymer complex (sulfonated polymer@FeOOH@PDA); (c) the sandwich The type polymer compound can be calcined in an inert gas atmosphere, or can be calcined with a volatile sulfur source, selenium source or phosphorus source in an inert gas atmosphere. By compounding iron elements on the surface of sulfonated polymer particles and then compounding polydopamine, a double-carbon layer ...

Embodiment 1

[0028] This embodiment provides a method for preparing a hollow sandwich iron-based negative electrode material, which includes the following steps:

[0029] (a) Ultrasonic dispersion of sulfonated polystyrene microspheres (SPS, 0.1 g, about 500 nm in diameter) into 200 mL of Fe(NO 3 ) 3 ·6H 2 O (0.54g) in an aqueous solution, and then use a water bath to heat the solution to 85°C and react for 30 minutes; centrifuge the solution, and wash with water and ethanol in turn; put the obtained red solid in an oven and dry it at 60°C for 24 SPS@FeOOH with core-shell structure was obtained in 1 hour;

[0030] (b) ultrasonically disperse the product (0.1 g) in step (a) in an aqueous buffer solution containing Tris (25 mM, trishydroxymethylaminomethane), and add dopamine (DA, 0.05 g) to the solution under stirring, Continue to stir and react at room temperature for 24 hours (during this period, DA polymerizes on the surface of SPS@FeOOH to generate polydopamine (PDA)); after the reac...

Embodiment 2

[0033] This embodiment provides a method for preparing a hollow sandwich-type iron-based negative electrode material, the preparation process of which is basically the same as that in Example 1, except that the sulfur powder is replaced with selenium powder during the calcining in step (c). Spherical C@FeSe@C composites with a hollow “sandwich” structure, whose electrochemical performance is shown in Figure 7 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com