A kind of xylo-oligosaccharide-containing abalone nutritional compound feed and its preparation method and application

A technology of compound feed and xylo-oligosaccharides, which is applied in application, animal feed, animal feed, etc., can solve problems such as unfavorable large-scale abalone farming, affecting normal activities of abalone, and deteriorating culture environment, so as to inhibit the growth of harmful bacteria and reduce Feed conversion rate and the effect of increasing feed coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

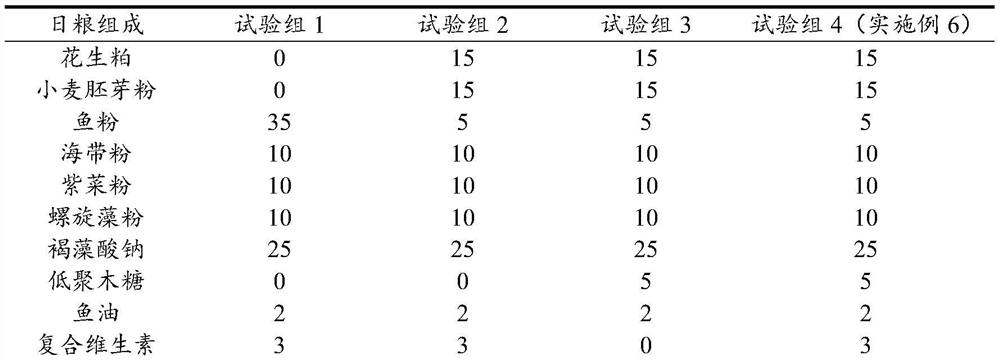

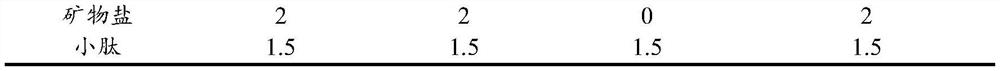

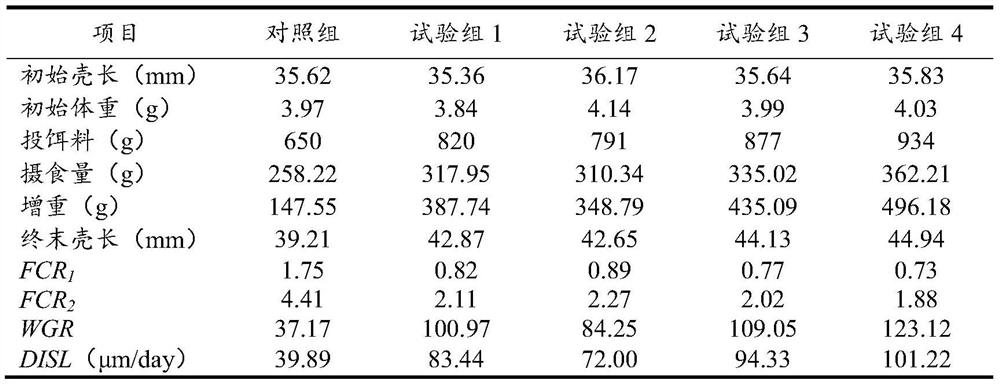

Method used

Image

Examples

preparation example Construction

[0044] In addition, the embodiment of the present invention also provides a preparation method of the abalone nutritional compound feed containing xylo-oligosaccharide, which mainly includes the following steps: mixing raw materials according to the proportion, then pressing, aging and drying.

[0045] Specifically, the raw materials can be mixed according to the following steps: first mix peanut meal, wheat germ, fish meal, multivitamins, compound mineral salts and xylooligosaccharides to obtain the first mixture; add gum additives, brown algae sodium nitrite and fish oil to obtain the second mixture.

[0046] First mix peanut meal, wheat germ, fish meal, multivitamins, compound mineral salts, xylooligosaccharides and small peptides as the raw materials of the main nutritional components, so that the above raw materials can be fully mixed to obtain the first mixture with relatively uniform tissue and nutrition ;Add gum additives, sodium alginate and fish oil to the first mixt...

Embodiment 1

[0058] 10 parts by weight of peanut meal, 10 parts by weight of wheat germ, 5 parts by weight of fish meal, 1 part by weight of multivitamins, 2 parts by weight of compound mineral salts, 3 parts by weight of xylooligosaccharides, 1 part by weight of small The peptide and water were mixed and stirred under the condition of 90 r / min to obtain the first mixture. Wherein, the proportioning relationship between water and the total weight of the above seven raw materials is 20mL: 1g.

[0059] Add 15 parts by weight of gum additives, 20 parts by weight of sodium alginate and 1 part by weight of fish oil into the first mixture to obtain the second mixture. Wherein, the gum additive includes 5 parts by weight of kelp, 5 parts by weight of laver and 5 parts by weight of spirulina.

[0060] The second mixture was rolled out to a thickness of 0.5 mm and then formed into circular sheets in a mold with a diameter of 10 mm. Then put the pressed round flakes in a steam curing cylinder, inp...

Embodiment 2

[0064] 15 parts by weight of peanut meal, 15 parts by weight of wheat germ, 10 parts by weight of fish meal, 2 parts by weight of multivitamins, 3 parts by weight of compound mineral salts, 5 parts by weight of xylooligosaccharides, 2 parts by weight of small The peptide and water were mixed and stirred under the condition of 90 r / min to obtain the first mixture. Wherein, the proportioning relationship between water and the total weight of the above seven raw materials is 20mL: 1g.

[0065] Add 30 parts by weight of gum additives, 25 parts by weight of sodium alginate and 2 parts by weight of fish oil into the first mixture to obtain the second mixture. Wherein, the glue additive includes 10 parts by weight of kelp, 10 parts by weight of seaweed and 10 parts by weight of spirulina.

[0066] The second mixture was rolled out to a thickness of 0.5 mm and then formed into circular sheets in a mold with a diameter of 10 mm. Then put the pressed round flakes in a steam curing cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com