Precise Rebound Corneal Dyeing Needle

A technology of dyeing needles and elastic cornea, which is applied in the field of medical devices, can solve the problems of accurate springback corneal dyeing needles that have not been reported, and achieve the effect of simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

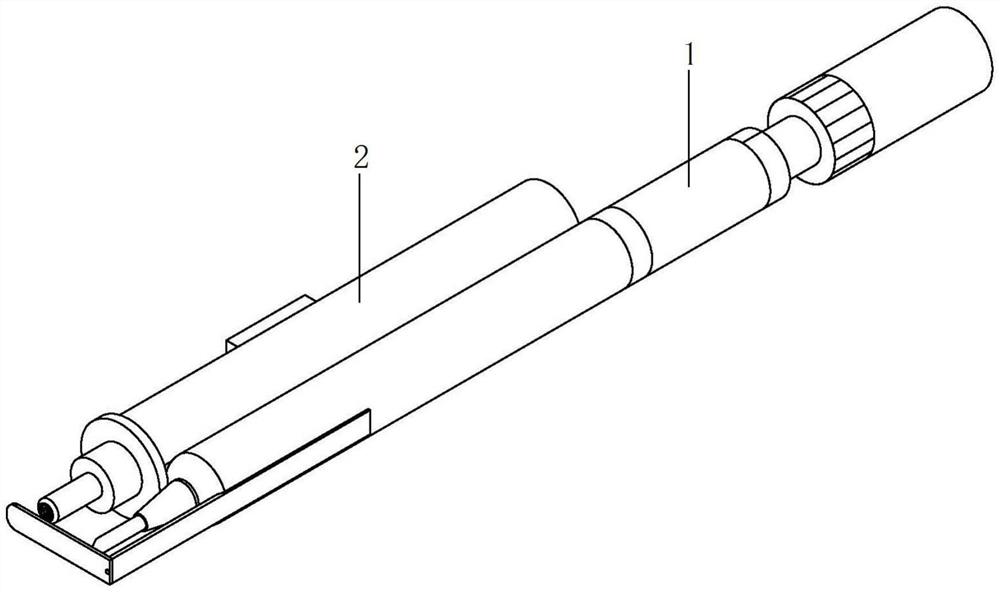

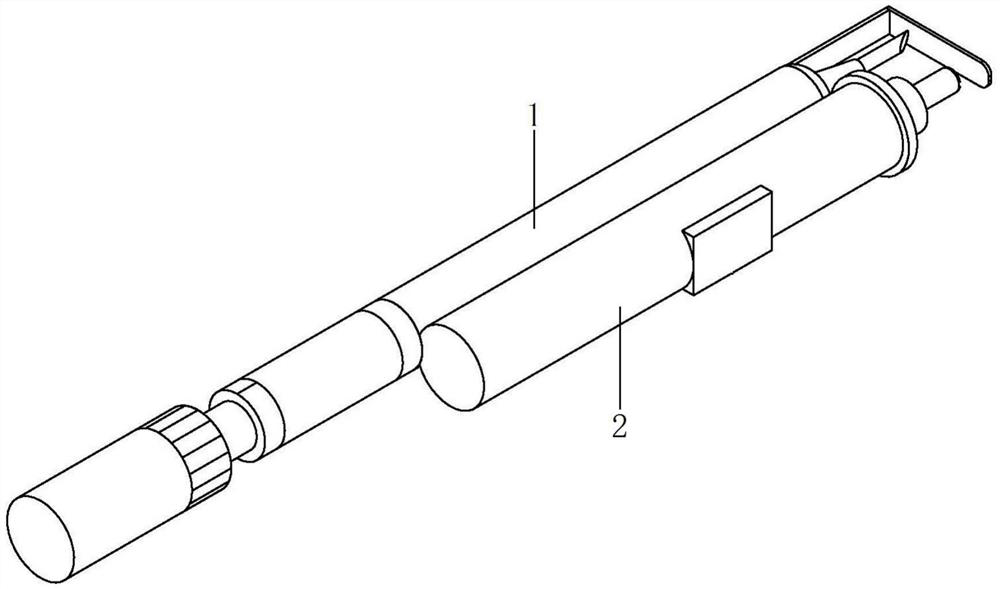

[0054] Please refer to the attached figure 1 , attached figure 2 , attached Figure 7 , with figure 1 , 2 It is a structural schematic diagram of a precise rebound corneal dyeing needle in this embodiment, with Figure 7 It is a schematic diagram of the internal integrated circuit of a precise rebound corneal dyeing needle of the present embodiment. The precise rebound corneal dyeing needle includes a differential dyeing needle 1 , an ultrasonic detection system 2 and an internal integrated circuit 3 .

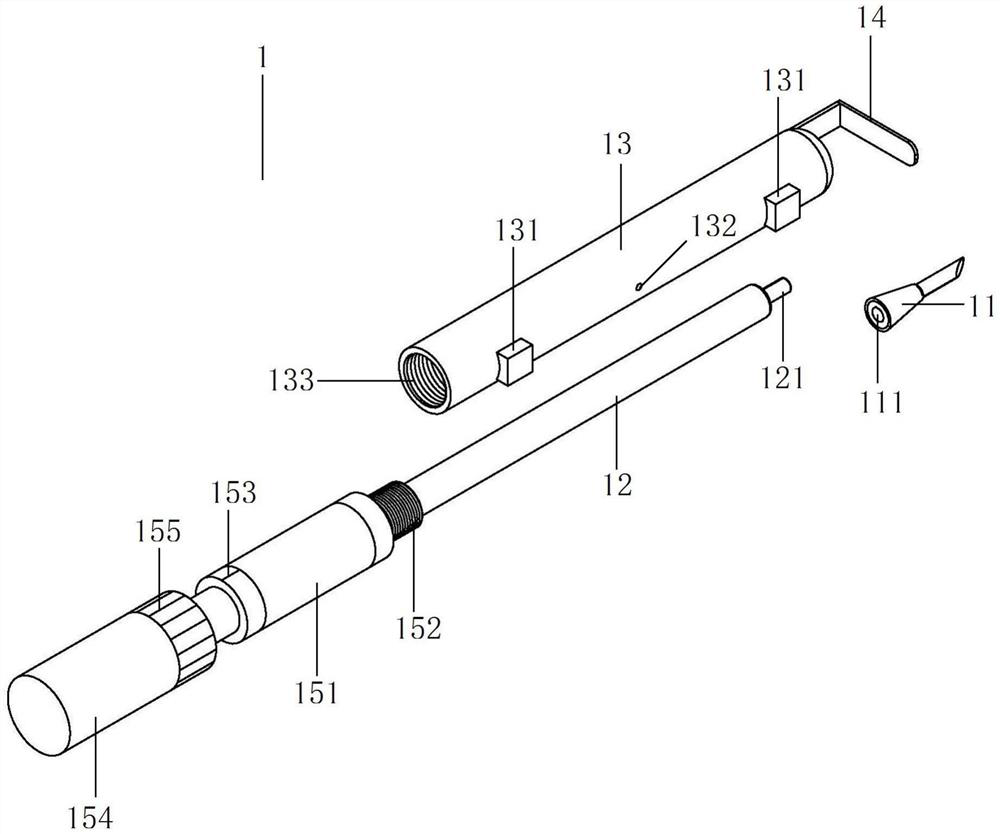

[0055] Please refer to the attached image 3 , attached Figure 5 , attached Figure 6 , with image 3 It is a schematic diagram of the differential dyeing needle structure of a precise rebound corneal dyeing needle in this embodiment, with Figure 5 It is a schematic diagram of the structure of the dyeing needle and the push rod of a precise rebound corneal dyeing needle in this embodiment, with Figure 6 It is a structural schematic diagram of a differential ruler...

Embodiment 2

[0060] Please refer to attached figure 1 , attached figure 2 , attached Figure 7 , with figure 1 , 2 It is a structural schematic diagram of a precise rebound corneal dyeing needle in this embodiment, with Figure 7 It is a schematic diagram of the internal integrated circuit of a precise rebound corneal dyeing needle of the present embodiment.

[0061] The use process and method of the precise rebound corneal dyeing needle:

[0062] First put the dyeing needle 11 on the ordinary syringe, and then use the ordinary syringe to extract a very small amount of dyeing agent into the dyeing needle 11; the inside of the dyeing needle 11 is hollow and can store a very small amount of dyeing agent; then pull out the dyeing needle 11, Through the bushing hole 111, it is set on the bushing 121 on the head of the push rod 12 .

[0063] Ultrasonic sensor 39 and ultrasonic transmitting and receiving circuit 38 are arranged in ultrasonic microprobe 21, can transmit and receive ultraso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com