A kind of ultrathin-walled chitosan microcapsule and preparation method thereof

A chitosan and ultra-thin-wall technology is applied in the field of chitosan microcapsule preparation, which can solve the problems of complex operation, poor stability, complex structure, etc., and achieve the effects of good appearance, improved safety and good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

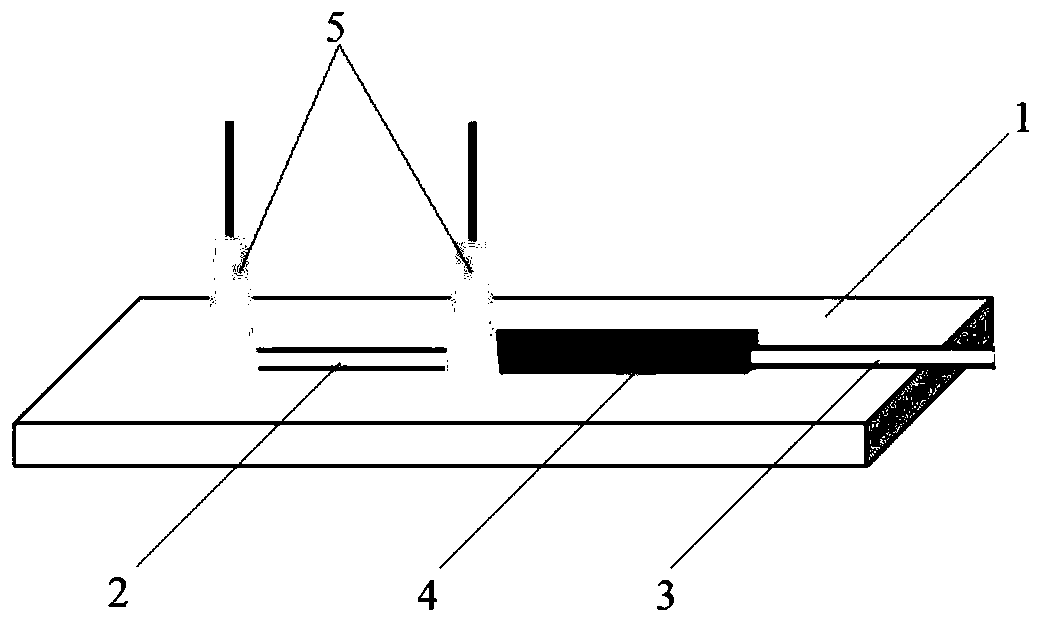

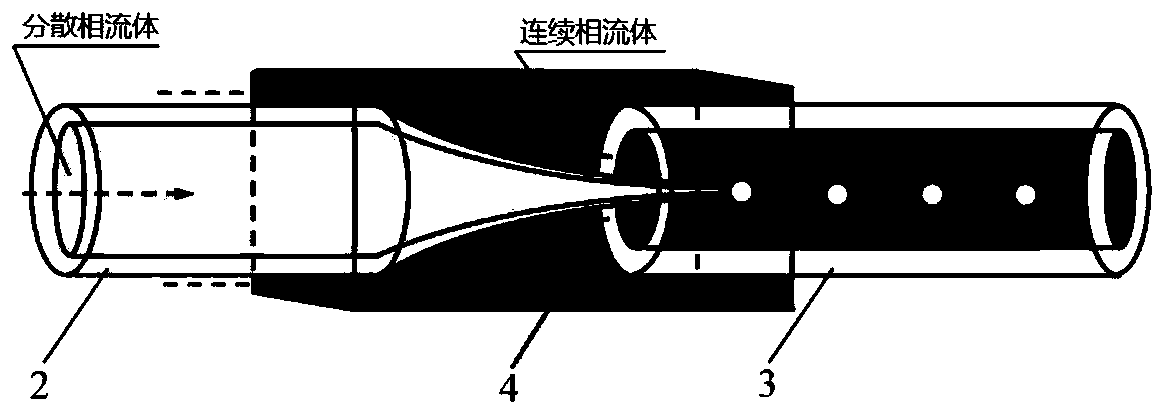

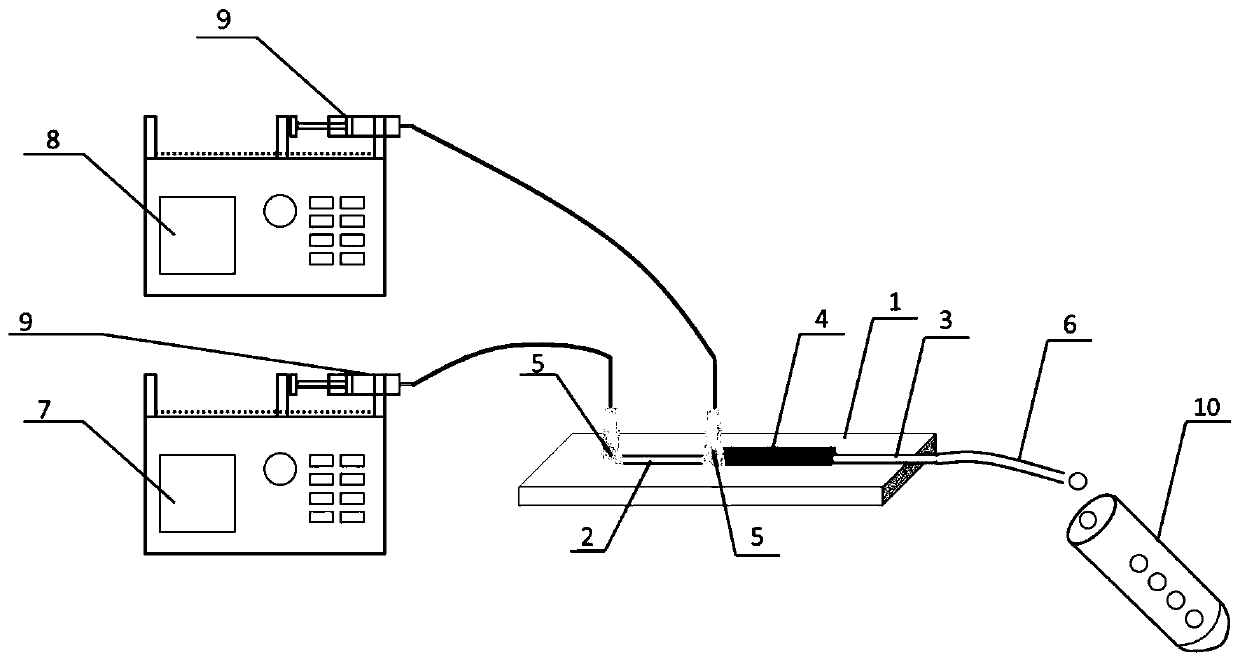

Method used

Image

Examples

Embodiment 1

[0057] In the present embodiment, the ultrathin-walled chitosan microcapsules are prepared, and the steps are as follows:

[0058] (1) Preparation of dispersed phase and continuous phase fluid

[0059] Prepare the dispersed phase fluid: add terephthalaldehyde into the soybean oil at room temperature, stir well until the terephthalaldehyde dissolves in the soybean oil to obtain the dispersed phase fluid, the concentration of terephthalaldehyde in the dispersed phase fluid is 0.0075g / mL;

[0060] Preparation of continuous phase fluid: at room temperature, water-soluble chitosan with a deacetylation degree of 85%, a weight average molecular weight Mw≤5000g / mol, and hydroxyethyl cellulose with a weight average molecular weight Mw=500000g / mol were added to deionized water , fully stirred until dissolved, then adjust the pH value to 6.4 with 1mol / L NaOH solution to obtain the continuous phase fluid, in the continuous phase fluid, the concentration of water-soluble chitosan is 0.02...

Embodiment 2

[0075] In the present embodiment, the ultrathin-walled chitosan microcapsules are prepared, and the steps are as follows:

[0076] (1) Preparation of dispersed phase and continuous phase fluid

[0077] Preparation of dispersed phase fluid: Prepare three different concentrations of dispersed phase fluid, add three parts of terephthalaldehyde to three parts of soybean oil at room temperature, stir well until terephthalaldehyde dissolves in soybean oil to obtain three concentrations Different dispersed phase fluids, the concentrations of terephthalaldehyde in the three dispersed phase fluids are 0.0005g / mL, 0.00075g / mL and 0.0015g / mL respectively;

[0078] Preparation of continuous phase fluid: at room temperature, water-soluble chitosan with a deacetylation degree of 85%, a weight average molecular weight Mw≤5000g / mol, and hydroxyethyl cellulose with a weight average molecular weight Mw=500000g / mol were added to deionized water , fully stirred until dissolved, then adjust the p...

Embodiment 3

[0089] In the present embodiment, the ultrathin-walled chitosan microcapsules are prepared, and the steps are as follows:

[0090] (1) Preparation of dispersed phase and continuous phase fluid

[0091] Prepare the dispersed phase fluid: add terephthalaldehyde into the soybean oil at room temperature, stir well until the terephthalaldehyde dissolves in the soybean oil to obtain the dispersed phase fluid, the concentration of terephthalaldehyde in the dispersed phase fluid is 0.0075g / mL;

[0092] Prepare continuous phase fluid: prepare three kinds of continuous phase fluids with different water-soluble chitosan concentrations, three parts of water-soluble chitosan with deacetylation degree of 85%, weight average molecular weight Mw≤5000g / mol at room temperature, and three parts Add three parts of hydroxyethyl cellulose with weight average molecular weight Mw=500000 g / mol to three parts of deionized water, fully stir until dissolved, then adjust the pH value to 6.4 with 1mol / L ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com