Plasma continuous modification method for modifying nano or micro particles

A technology of nanoparticles and particles, which is applied in the field of continuous modification and modification of nanoparticles by ion plasma method, can solve the problems of complex processing steps, reaction conditions, harsh environmental requirements, low reaction efficiency, etc. Effect of modified treatment, efficiency and yield improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

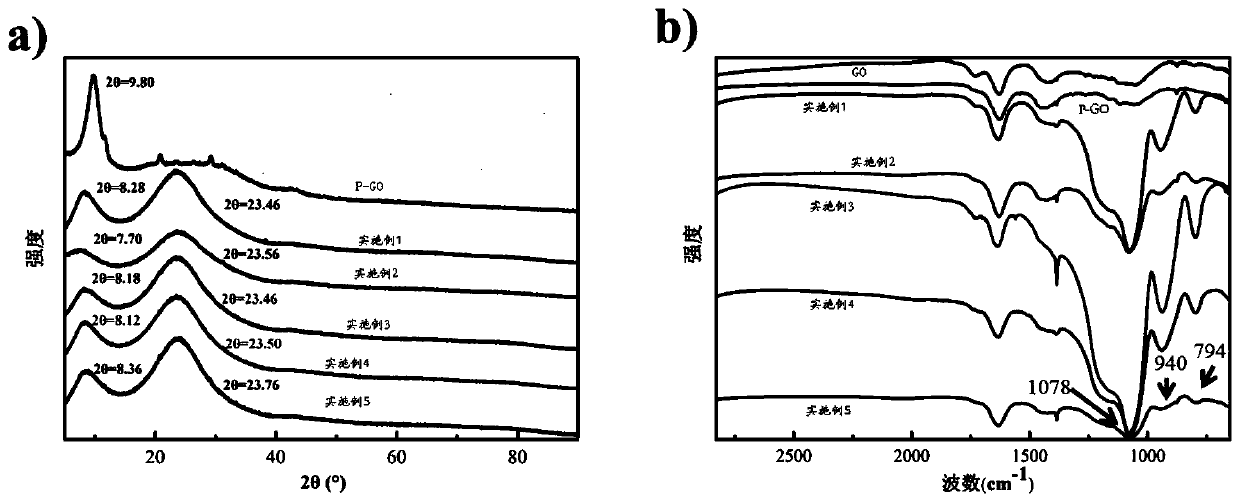

[0039] The present invention takes graphene oxide (GO) nanoparticles as an example, and prepares structured silicon dioxide (SiO2) on its surface through atmospheric pressure sliding arc plasma. 2 ) cladding layer, the specific method is as follows:

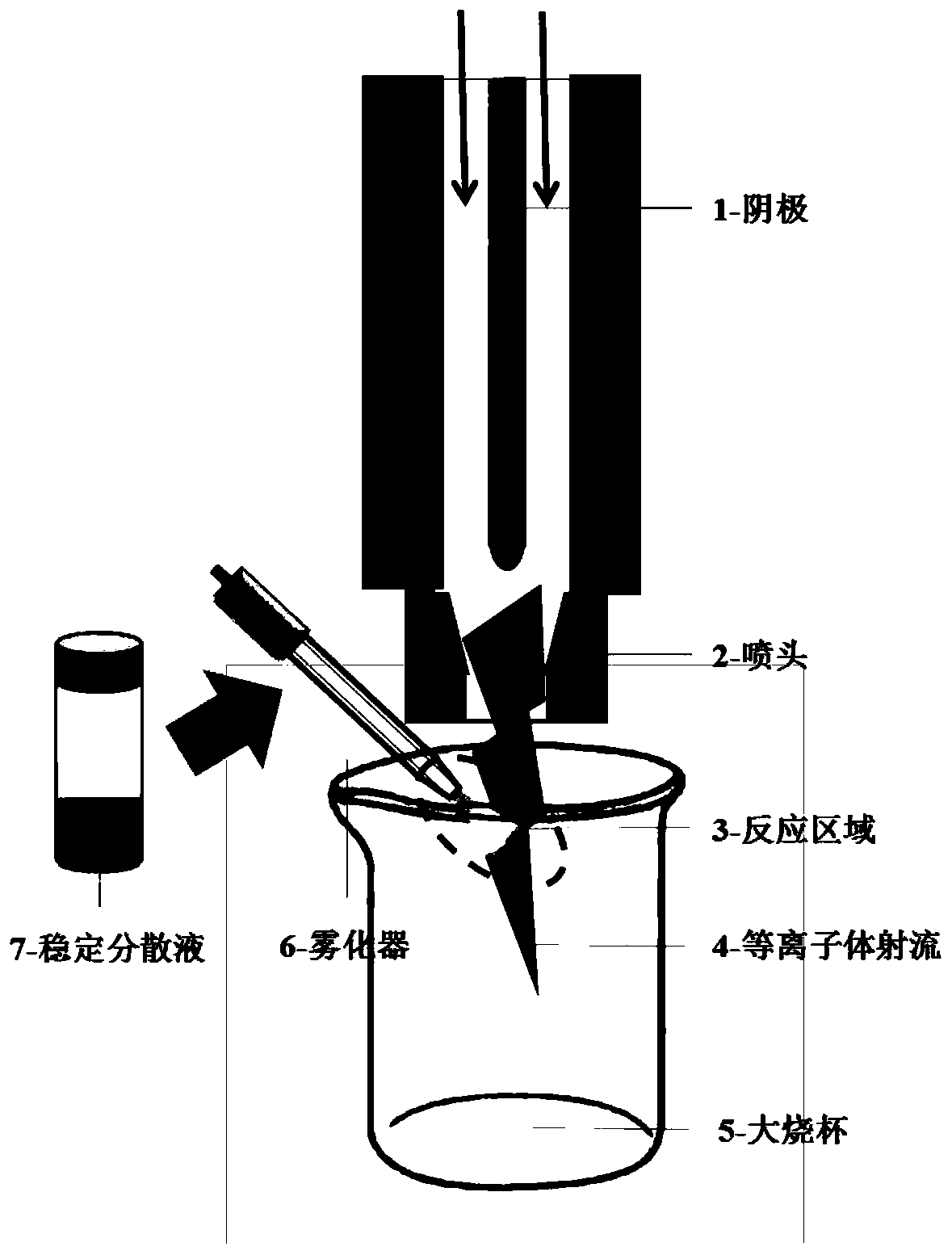

[0040] Disperse 100mg of GO and 3mg of TEOS into a mixed solvent of 50ml of water / 50ml of ethanol, and ultrasonicate at low temperature for more than 3 hours to obtain a uniformly mixed GO / TEOS dispersion; The gas flow rate of the atomizer is controlled at 3-4L / min, and the liquid atomization rate is controlled at 5ml / min; the atomizer nozzle is fixed at a certain angle near the plasma nozzle, so that the atomized aerosol coincides with the discharge area, and the reactants pass through the plasma In the bulk discharge area, the residence time is about 30-50 milliseconds, and finally collected by a large beaker (the process diagram and some structures are as follows figure 1 shown); among them, the plasma discharge gas source is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com