A kind of bayberry-like polydopamine core-gold-shell nanocomposite material and preparation method thereof

A polydopamine core-gold-shell, nanocomposite material technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the complex preparation process, low controllability of morphology, and a lot of inconvenience Preparation and other problems, to achieve the effect of reducing the reaction rate, the equipment is simple and easy to operate, and inhibiting spontaneous nucleation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] 1) Preparation of polydopamine nanospheres:

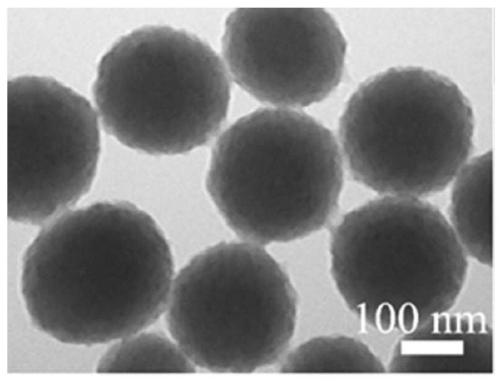

[0046] Mix ethanol with a 28% alkali solution in a mass ratio of 16:1, and the alkali solution is ammonia; and then prepare an aqueous dopamine solution with a concentration of 6%. Then according to the mass ratio of dopamine to the ethanol-base solution of 1:60, the dopamine aqueous solution and the ethanol-base solution were mixed, stirred for 20 hours, and washed by centrifugation at a speed of 12000 rpm to obtain polydopamine nanospheres, such as figure 1 Shown.

[0047] 2) Preparation of polydopamine sodium@金种 solution:

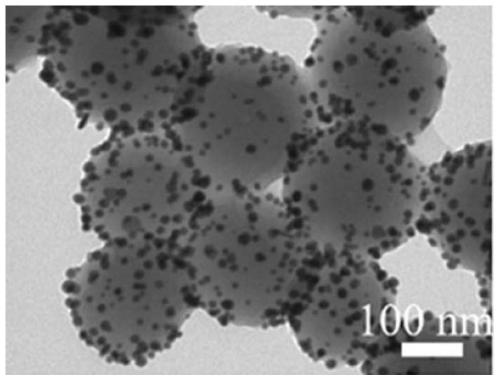

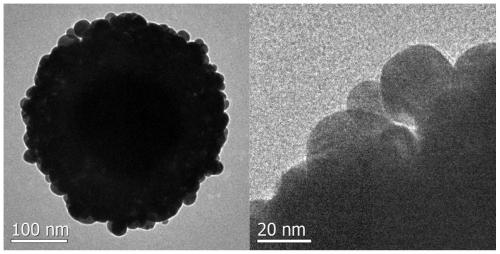

[0048] According to the mass ratio of 1% chloroauric acid to 8% polydopamine nanospheres, the chloroauric acid aqueous solution was added dropwise to the polydopamine nanospheres aqueous solution, mixed ultrasonically, and then 1% aqueous solution of 0.5% reducing agent sodium borohydride was added to achieve Load nano-gold species on the surface of polydopamine nanospheres, that is, polydopamine sodium@金种so...

Embodiment 2

[0052] 1) Preparation of polydopamine nanospheres:

[0053] Mix ethanol with a 30% alkali solution in a mass ratio of 14:1, and the alkali solution is sodium hydroxide; then prepare a 4% dopamine aqueous solution. Then, according to the mass ratio of dopamine to the ethanol-base solution of 1:80, the dopamine aqueous solution and the ethanol-base solution were mixed, stirred for 30 hours, and washed by centrifugation at a speed of 12000 revolutions / min to obtain polydopamine nanospheres.

[0054] 2) Preparation of polydopamine sodium@金种 solution:

[0055] According to the mass ratio of 4% chloroauric acid and 6% polydopamine nanospheres, the chloroauric acid aqueous solution was added dropwise to the polydopamine nanospheres aqueous solution, mixed ultrasonically, and then 1.5% sodium citrate aqueous solution with a concentration of 0.3% reducing agent was added to achieve Load the nano-gold species on the surface of the polydopamine nanospheres, that is, polydopamine sodium@金种solut...

Embodiment 3

[0059] 1) Mix ethanol with a 29% alkali solution in a mass ratio of 8:1, and the alkali solution is potassium hydroxide; then prepare a 6% aqueous dopamine solution. Then according to the mass ratio of dopamine to the ethanol-base solution of 1:100, the dopamine aqueous solution and the ethanol-base solution were mixed, stirred for 30 hours, and centrifuged and washed at a speed of 12,000 revolutions / min to obtain polydopamine nanospheres.

[0060] 2) Preparation of polydopamine sodium@金种 solution:

[0061] According to the mass ratio of 3.5% chloroauric acid to 2.5% polydopamine nanospheres, the chloroauric acid aqueous solution was added dropwise to the polydopamine nanospheres aqueous solution, mixed ultrasonically, and then 2% of the 0.3% reducing agent ascorbic acid aqueous solution was added to achieve the The surface of the dopamine nanospheres is loaded with nano-gold species, that is, polydopamine sodium@金种solution, which is centrifuged and washed at a speed of 12000 rpm t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com