Near infrared absorption organic dyestuff based on alkynyl triphenylamine and perylene diimide and preparation method and application thereof

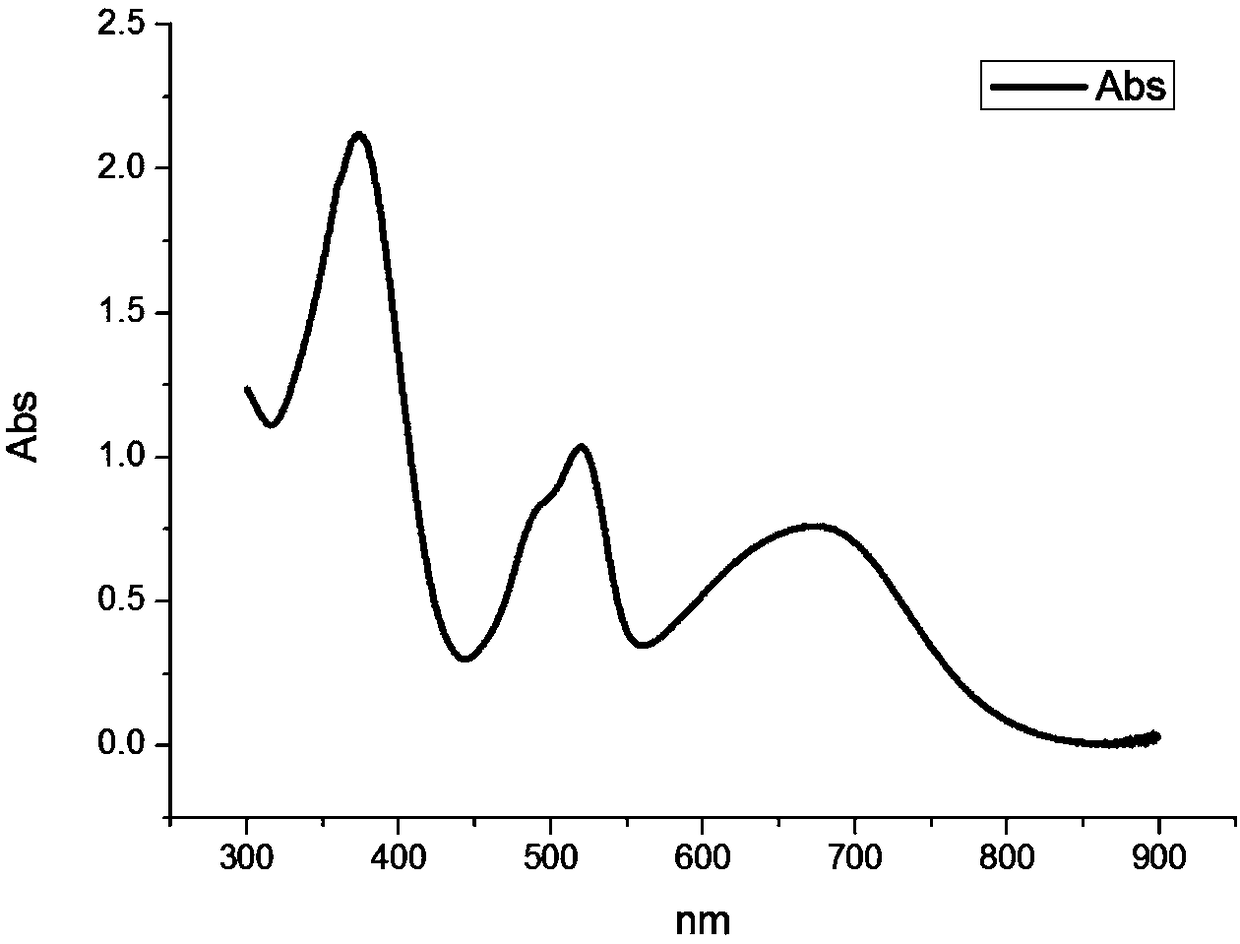

A technology of perylene diimide and alkynyl triphenylamine, which is applied in the directions of organic dyes, chemical instruments and methods, azo dyes, etc., can solve problems such as limited application, and achieve the effects of excellent light absorption performance, less pollution and simple steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0083]

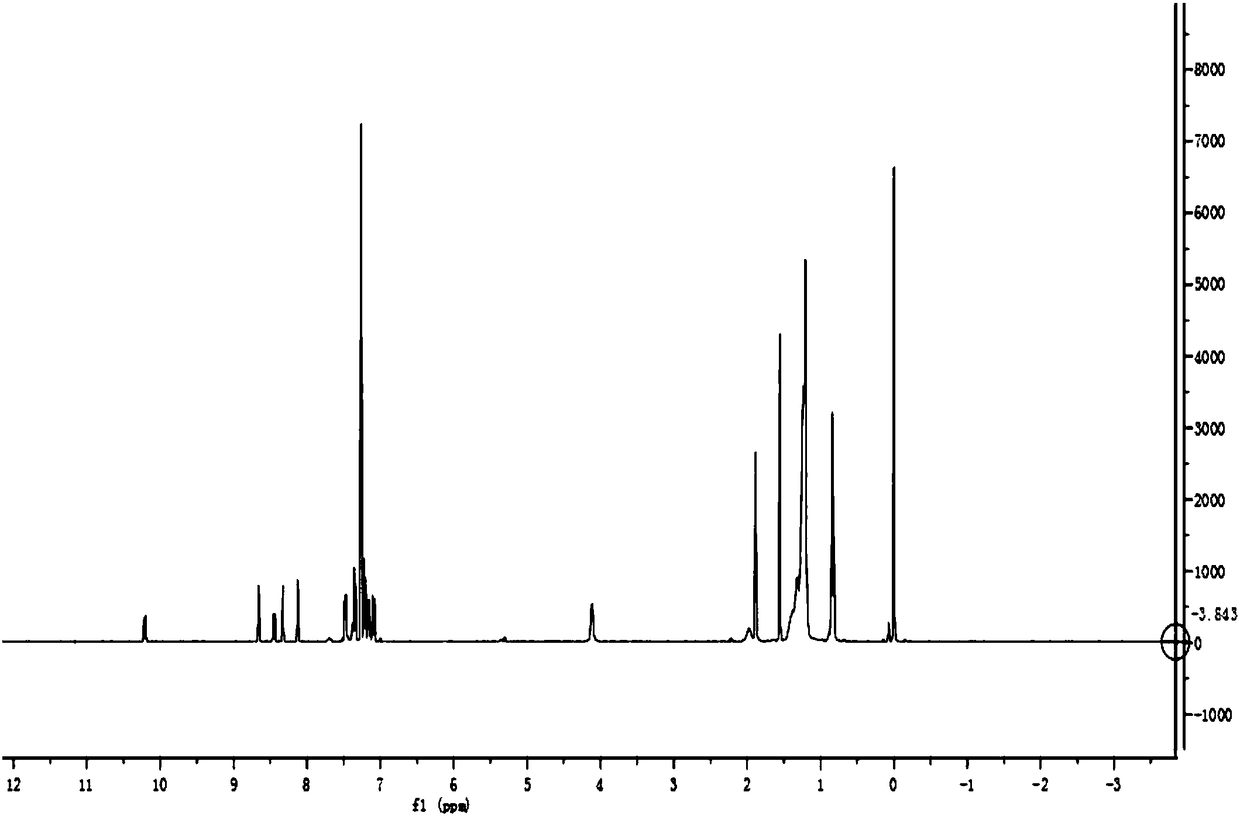

[0084] The 100mL reaction flask was evacuated and nitrogen protection, 300mg monobromoperylene diimide (1), 90mg monoalkynyltriphenylamine (2), 20mL anhydrous toluene, 5ml diisopropylamine, 100mg tetrakis (triphenyl Phosphine) palladium and 20 mg cuprous iodide were added to the reaction flask, the oil bath was turned on and heated to 80° C., the reaction was completed after 12 hours, and the obtained crude product was separated and purified by thin-layer chromatography to obtain 0.32 g of blue-purple product (3). E. LUMO =-3.70eV,E HOMO =-5.30eV, the yield was 85%.

Embodiment 2

[0086]

[0087] The 100ml reaction flask was evacuated and protected by nitrogen gas, 300mg monobromoperylene diimide (1) and 99mg dimethoxyalkynyltriphenylamine (4), 20mL anhydrous toluene, 5ml diisopropylamine, Add 100mg tetrakis(triphenylphosphine)palladium and 20mg cuprous iodide into the reaction flask, turn on the oil bath and heat to 80°C, the reaction ends after 12 hours, and the obtained crude product is separated and purified by thin-layer chromatography to obtain the blue-purple product ( 5) 0.29g, E LUMO =-3.71eV,E HOMO =-5.29eV, the yield was 80%.

Embodiment 3

[0089]

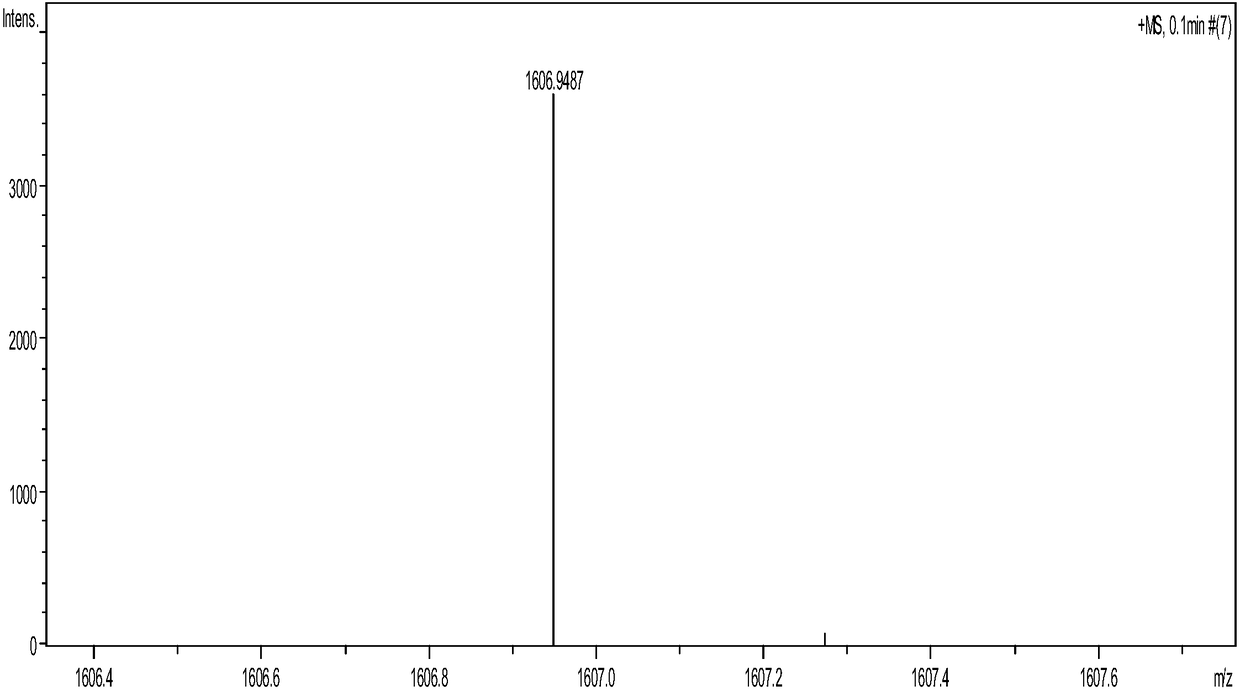

[0090] The 100mL reaction flask was evacuated and protected by nitrogen, weighed 306mg of bisbromoperylenediimide (6) and 186mg of alkynyltriphenylamine (2), 20mL of anhydrous toluene, 5ml of diisopropylamine, 100mg of tetrakis(triphenylamine) Phenylphosphine)palladium and 20mg of cuprous iodide were added to the reaction flask, and the oil bath was turned on to heat to 80°C. The reaction was completed after 12 hours. The obtained crude product was separated and purified by thin-layer chromatography to obtain 0.28g of blue-purple product (7) ,E LUMO =-4.0eV, E HOMO =-5.56eV, the yield was 68%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com