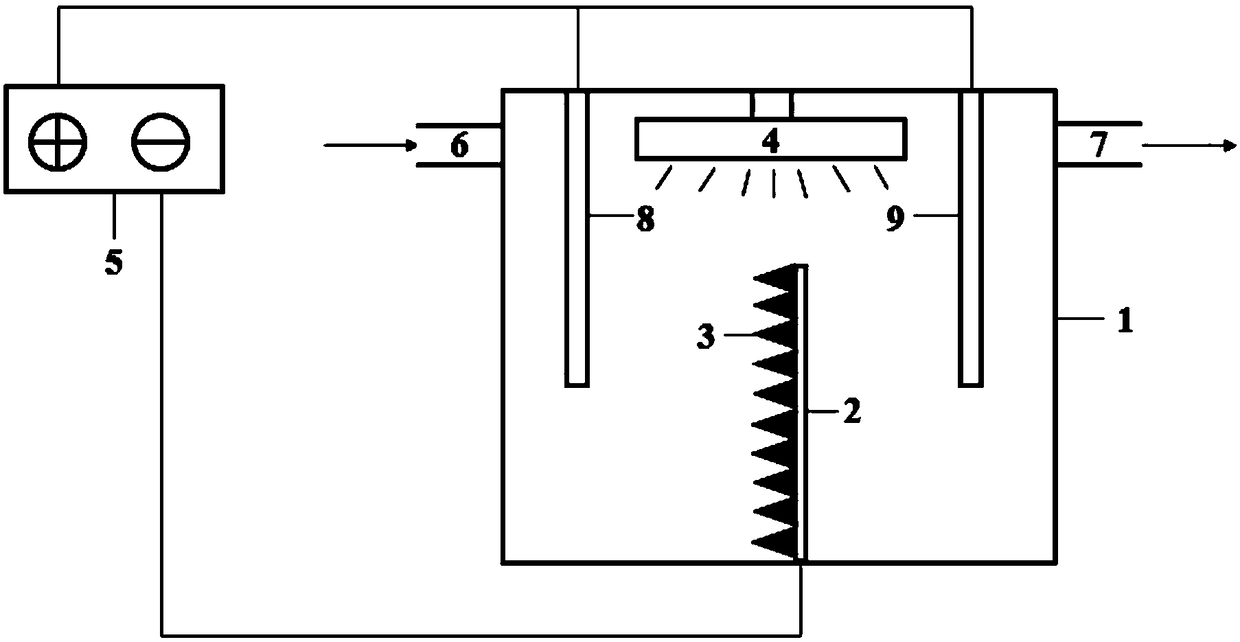

Device and method for treating high-concentration organic wastewater by cooperation of electrochemistry and photocatalysis

A technology for synergistic treatment of organic wastewater, applied in chemical instruments and methods, light water/sewage treatment, oxidized water/sewage treatment, etc., to achieve the effects of reducing compounding, low maintenance cost, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1) Visible light is selected as the catalytic light source, the conductive substrate is made of copper material, the two anodes are graphite electrodes, and the wastewater is high-concentration organic wastewater with a COD of 16870mg / L and a BOD of 35423mg / L;

[0035] 2)C 3 N 4 The preparation of macroporous carbon composite material comprises the following steps:

[0036] Dissolve 20 g of urea in 80 mL of deionized water, then add 15 mL of NaOH aqueous solution, mix well, dry at 120 °C, and then calcinate the obtained solid at 600 °C for 3 hours to obtain C with N defects 3 N 4 , 5 g of N-deficient C 3 N 4 Dissolve in 100mL deionized water, stir ultrasonically for 1 hour to obtain mixed solution A, add 1g of macroporous carbon material to 50mL deionized water, and ultrasonically stir for 30 minutes to obtain mixed solution B, slowly add mixed solution B to the mixed solution In A, hydrothermal reaction was carried out at 180°C in the reactor for 5 hours, and C wa...

Embodiment 2

[0040] 1) Visible light is selected as the catalytic light source, the conductive substrate is made of copper material, the two anodes are graphite electrodes, and the wastewater is high-concentration organic wastewater with a COD of 16870mg / L and a BOD of 35423mg / L;

[0041] 2)C 3 N 4 The preparation of macroporous carbon composite material comprises the following steps:

[0042] Dissolve 20 g of urea in 80 mL of deionized water, then add 15 mL of NaOH aqueous solution, mix well, dry at 120 °C, and then calcinate the obtained solid at 600 °C for 3 hours to obtain C with N defects 3 N 4 , 6.7 g of N-deficient C 3 N 4 Dissolve in 100mL deionized water, stir ultrasonically for 1 hour to obtain mixed solution A, add 1g of macroporous carbon material to 50mL deionized water, and ultrasonically stir for 30 minutes to obtain mixed solution B, slowly add mixed solution B to the mixed solution In A, hydrothermal reaction was carried out at 180°C in the reactor for 5 hours, and C ...

Embodiment 3

[0046] 1) Visible light is selected as the catalytic light source, the conductive substrate is made of copper material, the two anodes are graphite electrodes, and the wastewater is high-concentration organic wastewater with a COD of 16870mg / L and a BOD of 35423mg / L;

[0047] 2)C 3 N 4 The preparation of macroporous carbon composite material comprises the following steps:

[0048] Dissolve 20 g of urea in 80 mL of deionized water, then add 15 mL of NaOH aqueous solution, mix well, dry at 120 °C, and then calcinate the obtained solid at 600 °C for 3 hours to obtain C with N defects 3 N 4 , 8 g of N-deficient C 3 N 4 Dissolve in 100mL deionized water, stir ultrasonically for 1 hour to obtain mixed solution A, add 1g of macroporous carbon material to 50mL deionized water, and ultrasonically stir for 30 minutes to obtain mixed solution B, slowly add mixed solution B to the mixed solution In A, hydrothermal reaction was carried out at 180°C in the reactor for 5 hours, and C wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com