Polyester polyurethane high-gloss white stoving varnish and coating process thereof

A polyester polyurethane, white technology, applied in the field of coatings, can solve the problems of poor compatibility between polyester and amino resin, high volatile organic compounds, general weather resistance of paint film, etc., to improve storage stability, fullness Good degree and strong weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

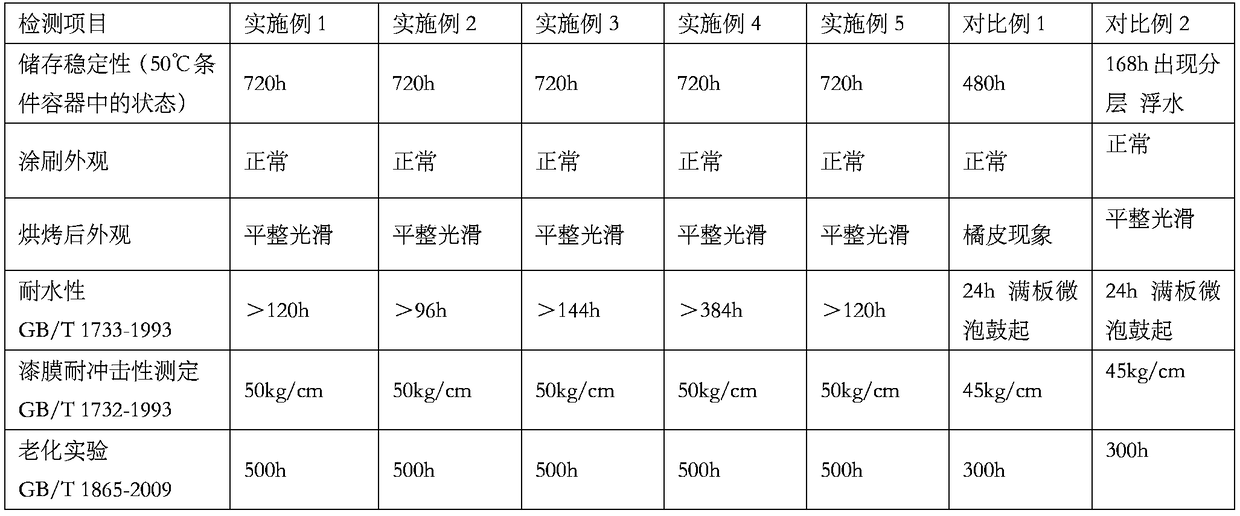

Examples

Embodiment 1

[0030] In this example, the polyester polyurethane high-gloss white baking varnish is obtained from the following raw materials in terms of mass percentage: 35.0 wt% polyester polyurethane resin, 2.0 wt% neutralizing agent dimethylethanolamine, dispersant BYK-190 1.0wt%, titanium dioxide DuPont R-706 is 20.0wt%, anti-settling agent organic bentonite is 1.0wt%, defoamer Airex 902 is 0.5wt%, fungicide ACTICIDE EPW is 1.5wt%, deionized water 39.0 wt%.

[0031] Wherein, the polyester polyurethane resin is prepared from the following raw materials in terms of mass percentage: trimethylolethane 16.0wt%, pentaerythritol 5.0wt%, pentaerythritol 15.0wt%, isophthalic acid 10.0wt% , 12.0wt% adipic acid, 17.0wt% propylene glycol diacetate, 7.0wt% dimethylol propionic acid, 18.0wt% partially blocked isocyanate curing agent.

[0032] Wherein, the partially blocked isocyanate curing agent is prepared from the following raw materials in terms of mass percentage: 45.0 wt% of polypropylene gly...

Embodiment 2

[0043] In this example, the polyester polyurethane high-gloss white baking varnish is obtained from the following raw materials in terms of mass percentage: 40.0 wt% polyester polyurethane resin, 1.5 wt% neutralizing agent dimethylethanolamine, dispersant BYK-190 0.5wt%, titanium dioxide DuPont R-706 is 10.0wt%, anti-settling agent organic bentonite is 0.2wt%, defoamer Airex 902 is 0.1wt%, fungicide ACTICIDE EPW is 0.7wt%, deionized water 47.0 wt%.

[0044] Wherein, the polyester polyurethane resin is prepared from the following raw materials in terms of mass percentage: 26.0wt% of trimethylolethane, 4.0wt% of pentaerythritol, 10.0wt% of pentaerythritol, and 6.0wt% of isophthalic acid , Adipic acid 8.0wt%, propylene glycol diacetate 15.0wt%, dimethylol propionic acid 9.0wt%, partially blocked isocyanate curing agent 22.0wt%.

[0045] Wherein, the partially blocked isocyanate curing agent is prepared from the following raw materials in terms of mass percentage: 55.0 wt% of pol...

Embodiment 3

[0056] In this example, the polyester polyurethane high-gloss white baking varnish is obtained from the following raw materials in terms of mass percentage: 45.0 wt% polyester polyurethane resin, 3.5 wt% neutralizing agent dimethylethanolamine, and dispersant BYK-190 3.0wt%, titanium dioxide DuPont R-706 is 17.0wt%, anti-settling agent organic bentonite is 0.5wt%, defoamer Airex 902 is 0.3wt%, fungicide ACTICIDE EPW is 0.7wt%, deionized water 30.0 wt%.

[0057] Wherein, the polyester polyurethane resin is prepared from the following raw materials in terms of mass percentage: 23.0wt% of trimethylolethane, 6.0wt% of pentaerythritol, 12.0wt% of pentaerythritol, and 8.0wt% of isophthalic acid , Adipic acid 10.0wt%, propylene glycol diacetate 12.0wt%, dimethylol propionic acid 11.0wt%, partially blocked isocyanate curing agent 18.0wt%.

[0058] Wherein, the partially blocked isocyanate curing agent is prepared from the following raw materials in terms of mass percentage: 53.0 wt% ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com