Coating method for enhancing environmental stability of multilayered laser film

An environmental stability, laser thin film technology, applied in optical components, coatings, optics, etc., can solve the problems of low anti-laser damage threshold, low anti-laser damage threshold, film cracking, thin film element failure, etc., to improve environmental stability Sexual, targeted and efficient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

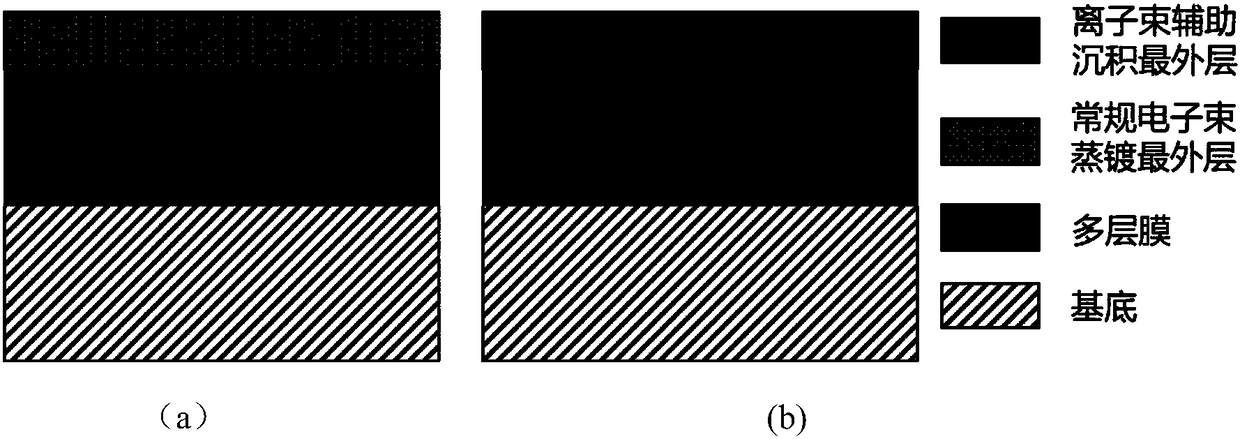

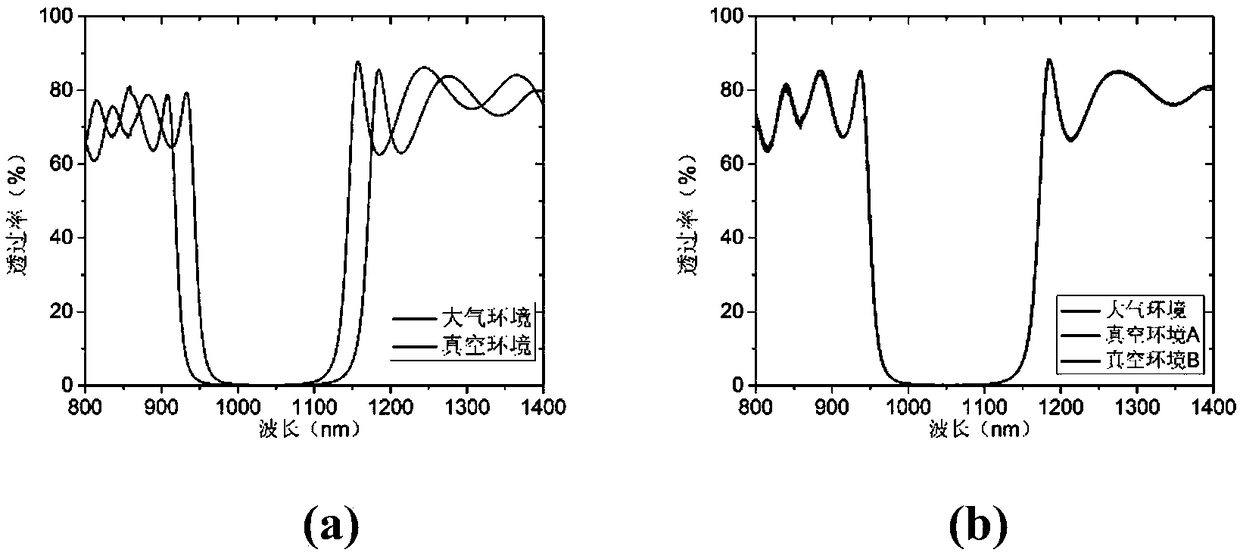

[0024] see first figure 1 , figure 1 It is a schematic diagram of the film system of the multilayer high reflection film prepared by conventional electron beam evaporation technology and the method of the present invention. The embodiment is based on the high refractive index material as HfO 2 , the low refractive index material is SiO 2 , the film system design is respectively: the multi-layer high reflection film of S | M B | A, S | HL) 12 H, B=N=4L, this technique comprises the following steps:

[0025] 1) Film system design:

[0026] According to the requirements of spectral performance: 0°R≥99.5%@1064nm, the designed film system is: S|4L(HL) 12 H 4L|A, where L represents the low refractive index material SiO 2 , H stands for high refractive index material HfO 2 , 4L layer is the protective layer;

[0027] 2) Substrate cleaning: the substra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com