Quantitative analysis method for total iron and alkalinity in sinter

A quantitative analysis and sintering technology, which is applied in the field of spectral quantitative analysis, can solve the problems that the single-variable correction model cannot satisfy the quantitative analysis, and achieve the effect of improving production line capacity, avoiding too slow correction speed, and broad market application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

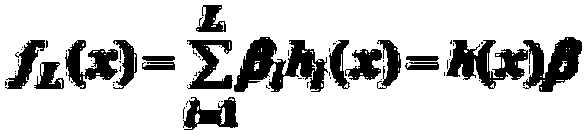

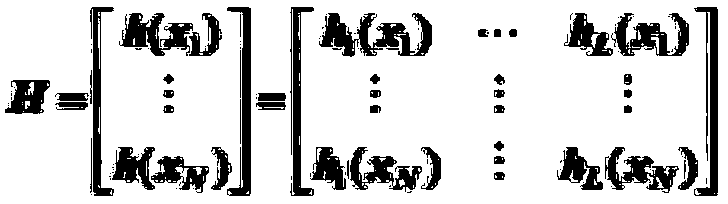

Method used

Image

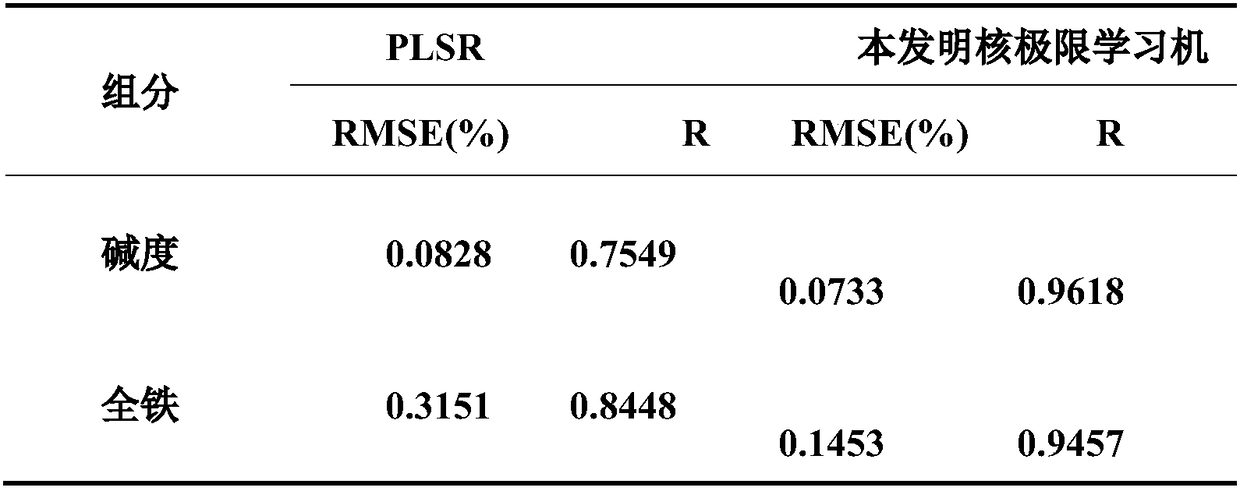

Examples

Embodiment 1

[0031] The laser-induced breakdown spectroscopy system in this example includes a Q-switched Nd:YAG laser with a wavelength of 1064nm, a laser repetition rate of 1Hz, a pulse width of 1ns, and a laser pulse energy of 150mj; a delayer with a delay accuracy of 10ns; a three-channel fiber optic spectrometer , the wavelength range is 200-500nm, the resolution is 0.07nm, tablet press. During the experiment, in order to obtain the spectrum with good signal-to-noise ratio, each spectrum is obtained by 20 signal accumulations. In order to prevent the detection of bremsstrahlung pulsed laser, the optimized laser energy is 80mJ, and the delay time is 3μs.

[0032] 1) Sample preparation: select 30 sinter samples with known composition content (Shigang Jingcheng Equipment Technology Co., Ltd.), each sinter sample is ground by a ball mill and passed through a 200-mesh sieve. In order to facilitate the experimental measurement, each sample was made into a thin slice with a thickness of abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com