Non-thermal sterilization micro-treatment chamber for blueberry juice, sterilization system and sterilization method

A technology of micro-processing chamber and blueberry juice, which is applied in the fields of food electrical processing and food science, can solve the problems of inaccurate control of operating parameters, high cost of high-voltage pulse generators, affecting the service life of the system, etc., so as to improve the experimental accuracy and shorten the Effect of electrode spacing, no pressure change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

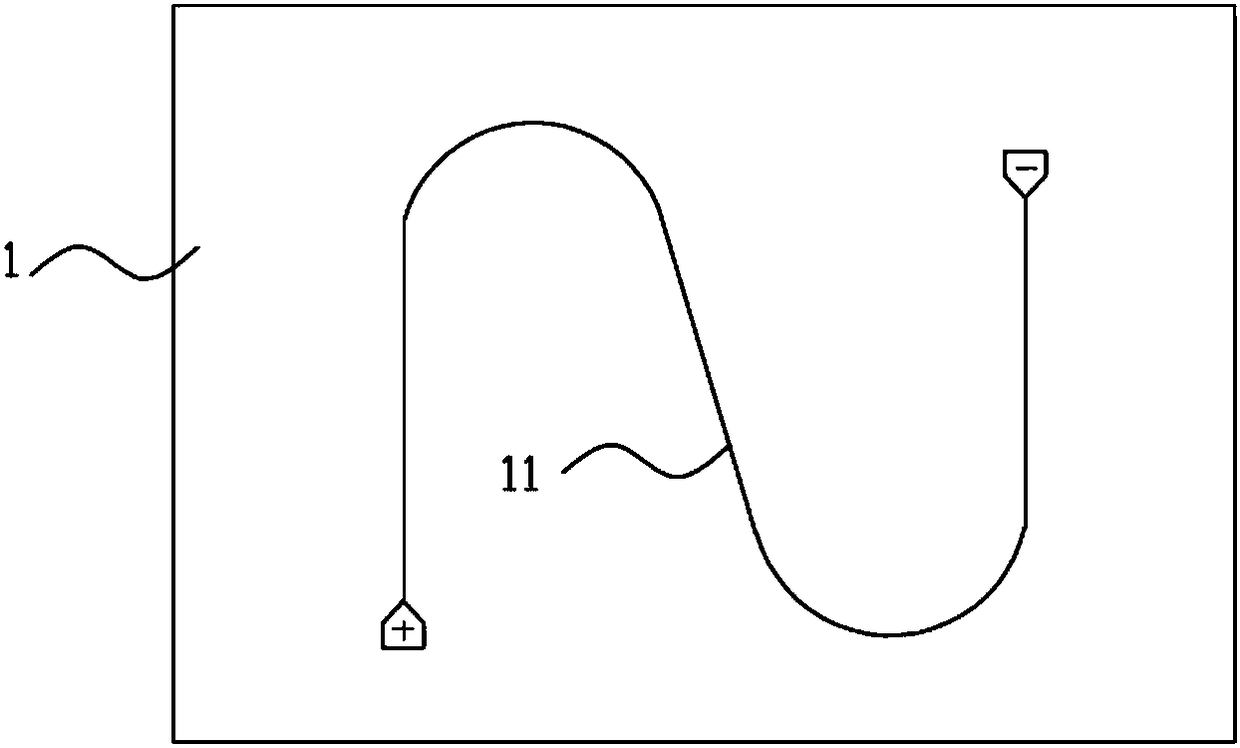

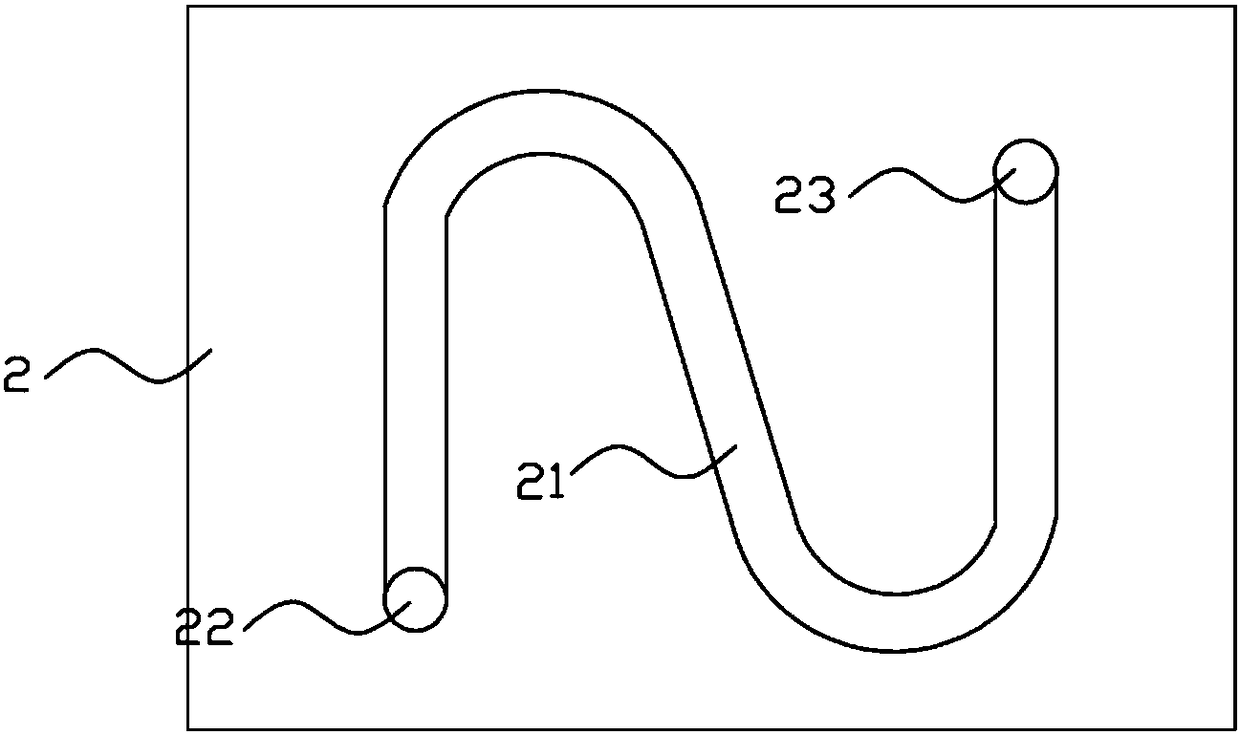

[0054] like figure 1 As shown, Embodiment 1 of the present invention provides a kind of blueberry juice non-thermal sterilization micro-processing chamber, comprising a base plate 1 and a packaging plate 2 arranged above the base plate 1, the top of the base plate 1 is etched with a microelectrode 11, the A fruit juice channel 21 is etched on the bottom of the packaging plate 2, and the top of the packaging plate 2 is located at the two ends of the juice channel 21 and is respectively provided with a juice inlet 22 and a juice outlet 23 communicating with the juice channel 21. The extension of the juice channel 21 The direction is the same as the current flow path of the microelectrodes 11 .

[0055] When in use, after the bottom plate 1 and the packaging plate 2 are fastened and sealed, the juice channel 21 can be combined with the bottom plate 1 to form a path for the juice to circulate. After the blueberry juice is injected from the juice inlet 22, it can flow along this pa...

Embodiment 2

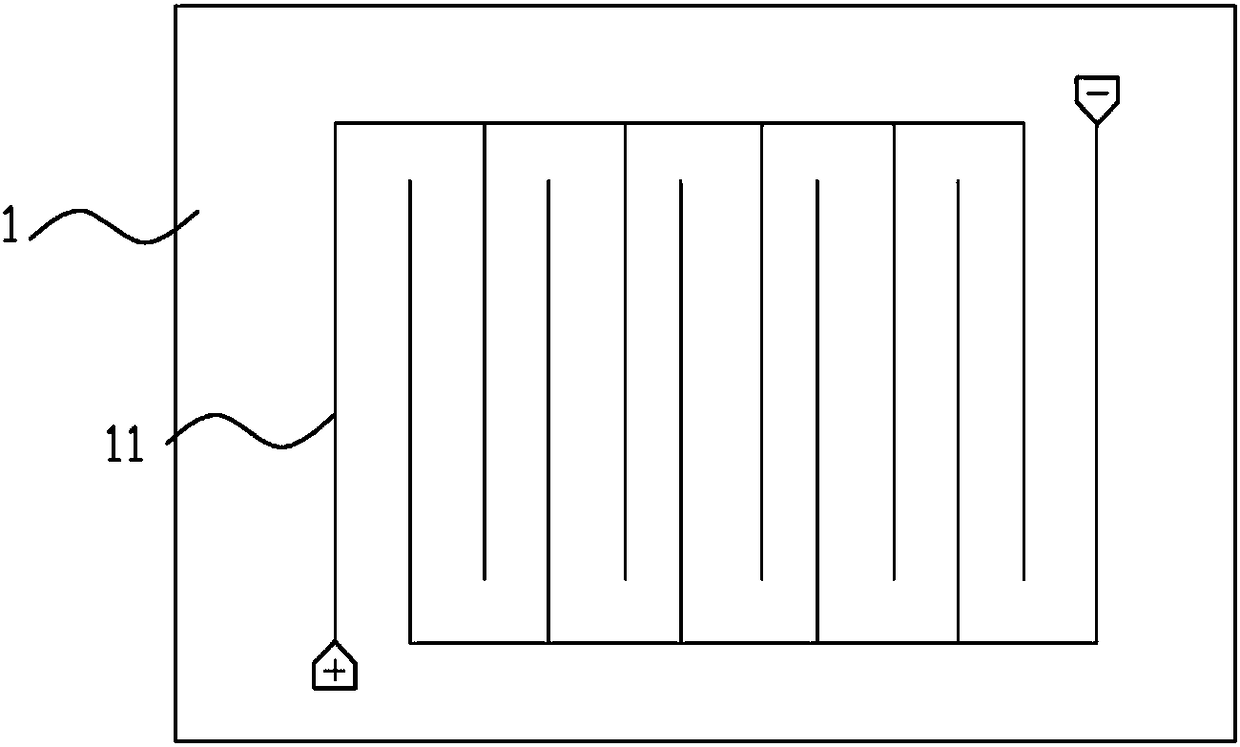

[0057] like figure 2 As shown, this embodiment 2 provides a kind of blueberry juice non-thermal sterilization micro-processing chamber on the basis of embodiment 1, and this embodiment 2 further defines that the microelectrode 12 is composed of a pair of comb-shaped electrodes intersecting In the interdigitated electrode structure, the distance between the positive and negative electrodes of the microelectrodes 12 is 100 μm, and the width of the comb teeth is 30 μm.

[0058] Juice channel 21 comprises 4 transverse grooves 24 and 5 longitudinal grooves 25 perpendicular to said transverse grooves 24, each transverse groove 24 two ends communicate with one end of two adjacent longitudinal grooves 25 respectively, the first longitudinal groove 25, one end away from the horizontal groove 24 communicates with the fruit juice inlet, and the fifth vertical groove 25 communicates with the fruit juice outlet 23 at one end away from the horizontal groove 24.

Embodiment 3

[0060] This embodiment 3 provides a kind of blueberry juice non-thermal sterilization micro-processing chamber on the basis of embodiment 2, and this embodiment 3 further defines that the distance between the positive and negative electrodes of the microelectrode 12 is 100 μm, and the central comb The width is 30 μm, and the width of the edge comb teeth is 40 μm; the widths of the longitudinal grooves 25 and the transverse grooves 24 are both 3 mm, and the distance between adjacent longitudinal grooves 25 is 0.5 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com