A preparation method of an oil-water separation membrane with underwater superoleophobic properties and antibacterial properties

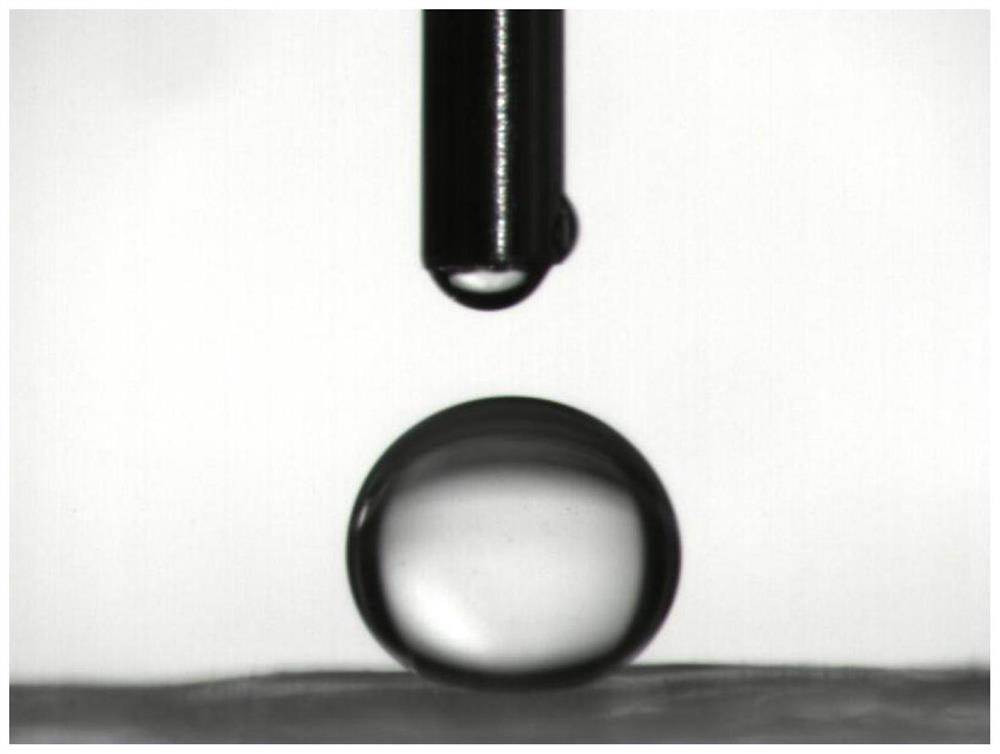

A technology of underwater super-oleophobic and oil-water separation membranes, applied in separation methods, chemical instruments and methods, liquid separation, etc., can solve the problems of non-super-hydrophilic/underwater super-oleophobic properties, separation efficiency and separation selectivity Not high enough, poor oil resistance and adhesion, etc., to achieve excellent super oleophobic properties, excellent antibacterial properties, and fast separation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A method for preparing an oil-water separation membrane with underwater superoleophobic properties and antibacterial properties, comprising the steps of:

[0038] 1) At room temperature, add 100ml of water and 3g of sodium alginate into a 250ml beaker, stir and mix evenly to obtain a 3wt% sodium alginate solution, and scrape the resulting sodium alginate solution on a glass plate, with a film thickness of about 70 μm;

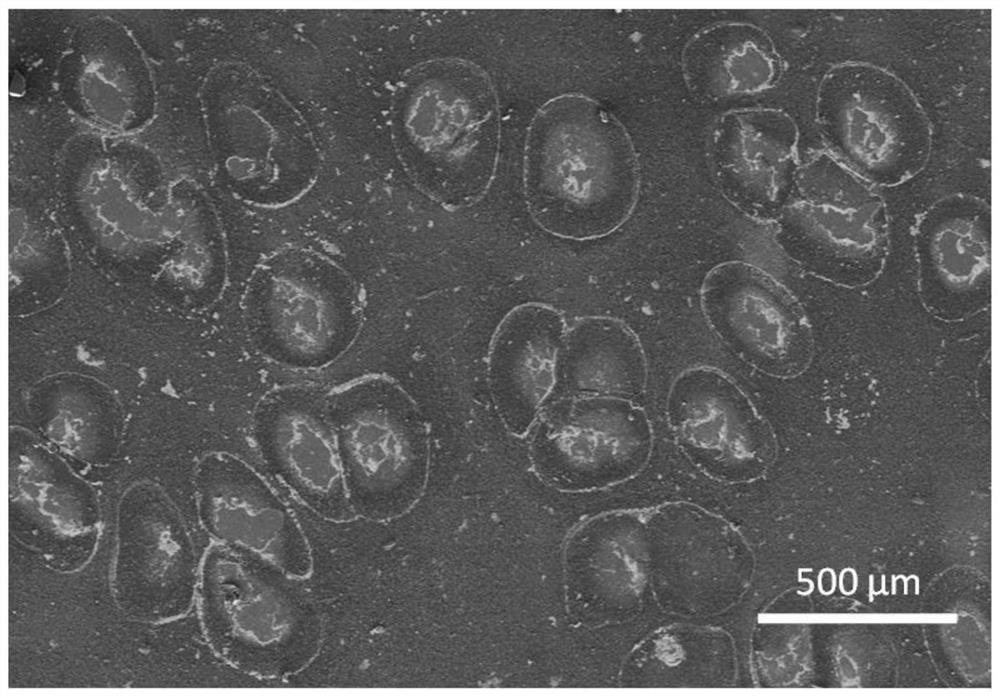

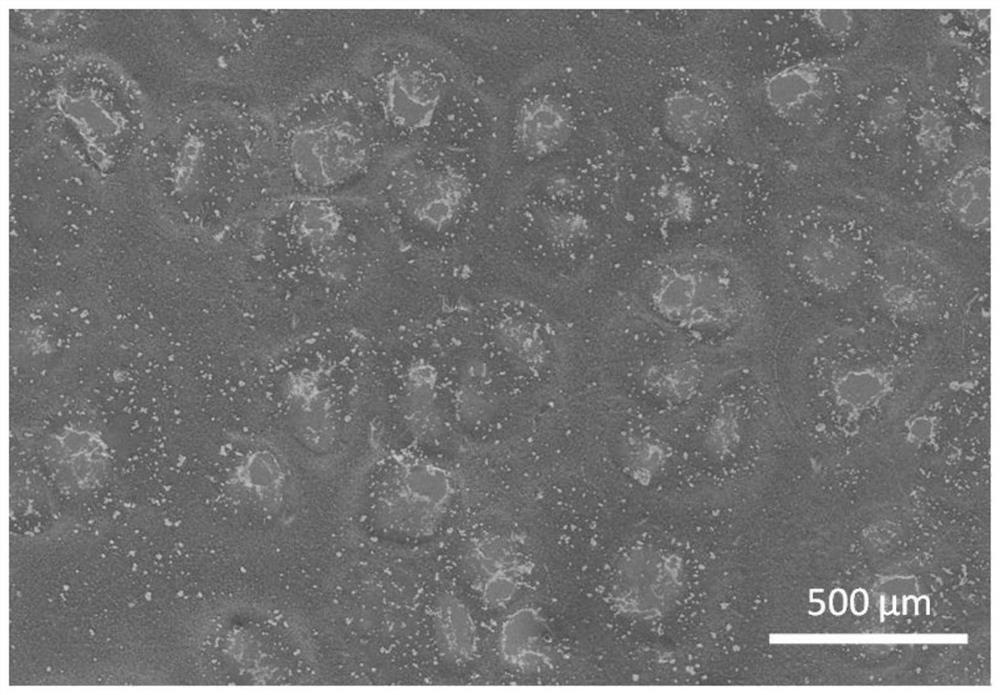

[0039] 2) Grind sodium chloride, sieve with a standard sieve, take 3 g of sodium chloride crystal particles with a particle diameter of about 300 μm for use, and sieve the sodium chloride crystal particles on the surface of the sodium alginate film obtained in step 1) , to get a mixed film;

[0040] 3) Immediately put the mixed film obtained in step 2) into a 5wt% calcium chloride solution for ultrasonication for 60s, and then soak the obtained initially cured film in a 5wt% calcium chloride solution for 6 hours to make it fully cross-linked, and use Wa...

Embodiment 2

[0048] A method for preparing an oil-water separation membrane with underwater superoleophobic properties and antibacterial properties, comprising the steps of:

[0049] 1) At room temperature, add 100ml of water and 0.5g of sodium alginate into a 250ml beaker, stir and mix evenly to obtain a 0.5wt% sodium alginate solution, and scrape the resulting sodium alginate solution on a glass plate, with a film thickness of about 20 μm;

[0050] 2) Grind sodium chloride, sieve with a standard sieve, take 0.05 g of potassium sulfate crystal particles with a particle diameter of about 20 μm for use, and sieve the sodium chloride crystal particles with a sieve on the surface of the sodium alginate film obtained in step 1) , to get a mixed film;

[0051] 3) Immediately put the mixed membrane obtained in step 2) into 0.01wt% ferric chloride solution for 30s, and then soak the obtained preliminarily cured membrane in 0.01wt% ferric chloride solution for 12h to make it fully cross-linked , ...

Embodiment 3

[0059] A method for preparing an oil-water separation membrane with underwater superoleophobic properties and antibacterial properties, comprising the steps of:

[0060] 1) At room temperature, add 100ml of water and 10g of sodium alginate into a 250ml beaker, stir and mix evenly to obtain a 10wt% sodium alginate solution, and scrape the resulting sodium alginate solution on a glass plate, with a film thickness of about 200 μm;

[0061] 2) Grind sodium sulfate, sieve with a standard sieve, take 20 g of sodium sulfate crystal particles with a particle diameter of about 500 μm for use, sieve the sodium sulfate crystal particles on the surface of the sodium alginate film obtained in step 1) with a sieve, and mix membrane;

[0062] 3) Immediately put the mixed film obtained in step 2) into a 10wt% hydrochloric acid solution for 180s, and then soak the obtained initially cured film in a 10wt% hydrochloric acid solution for 0.1h to fully cross-link it, and wash it with deionized wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com