A preparation method of underwater superoleophobic microgel/fiber composite

A fiber composite material and underwater super-oleophobic technology, applied in the field of functional materials, can solve problems such as poor mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A method for preparing a microgel / fiber composite with underwater superoleophobic properties, comprising the steps of:

[0038] 1) Dissolve 2-acrylamido-2-methylpropanesulfonic acid, N,N-methylenebisacrylamide and ammonium persulfate in water to obtain the first monomer solution, 2-acrylamido-2- The concentration of methylpropanesulfonic acid is 0.5 mol / L, the concentration of N,N-methylenebisacrylamide is 0.005 mol / L, and the concentration of ammonium persulfate is 0.005 mol / L;

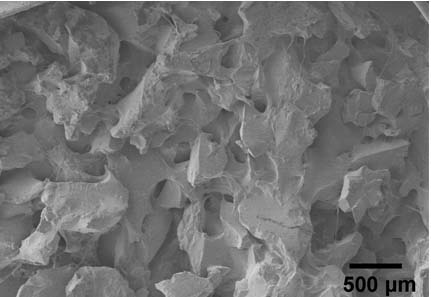

[0039] 2) The first monomer solution obtained in step 1) was heated at 80°C for 1 hour to obtain poly 2-acrylamido-2-methylpropanesulfonic acid hydrogel, crushed, dried, and then ground into micro Gel powder, the size is 300-500 μm;

[0040] 3) Dissolve acrylamide, N,N-methylenebisacrylamide, and ammonium persulfate in water to obtain a second monomer solution, the concentration of acrylamide is 1.0 mol / L, and N,N-methylenebisacrylamide The concentration is 0.0005 mol / L, and the concentratio...

Embodiment 2

[0045] A method for preparing a microgel / fiber composite with underwater superoleophobic properties, comprising the steps of:

[0046] 1) Dissolve acrylamide, N,N-methylenebisacrylamide and sodium persulfate in water to obtain the first monomer solution, the concentration of acrylamide is 3 mol / L, N,N-methylenebisacrylamide The concentration is 0.03 mol / L, and the concentration of sodium persulfate is 0.03 mol / L;

[0047] 2) Heating the first monomer solution obtained in step 1) at 90°C for 2 hours to obtain a polyacrylamide hydrogel, crushing it, drying it, and grinding it into a microgel powder with a size of 10-30 μm;

[0048] 3) Dissolve sodium p-styrenesulfonate, N,N-methylene bisacrylamide, and sodium persulfate in water to obtain a second monomer solution, the concentration of sodium p-styrenesulfonate is 6.0 mol / L, N, The concentration of N-methylenebisacrylamide is 0.003 mol / L, and the concentration of sodium persulfate is 0.06 mol / L;

[0049] 4) Mix the microgel po...

Embodiment 3

[0053] A method for preparing a microgel / fiber composite with underwater superoleophobic properties, comprising the steps of:

[0054] 1) Dissolve acrylic acid, N,N-methylenebisacrylamide and potassium persulfate in water to obtain the first monomer solution, the concentration of acrylic acid is 1.75 mol / L, and the concentration of N,N-methylenebisacrylamide is 0.0175 mol / L, the concentration of potassium persulfate is 0.0175 mol / L;

[0055] 2) Heating the first monomer solution obtained in step 1) at 85°C for 1.5 hours to obtain polyacrylic acid hydrogel, crushing, drying, and then grinding into microgel powder with a size of 700-800 μm;

[0056] 3) Dissolve N-vinylpyrrolidone, N,N-methylenebisacrylamide, and potassium persulfate in water to obtain a second monomer solution, the concentration of N-vinylpyrrolidone is 3.5 mol / L, N,N- The concentration of methylenebisacrylamide is 0.00175mol / L, and the concentration of potassium persulfate is 0.035mol / L;

[0057] 4) Mix the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com