Polyacrylamide polymerization reactor and control method thereof

A polymerization reactor, polyacrylamide technology, applied in chemical instruments and methods, control/adjustment processes, chemical/physical/physical-chemical stationary reactors, etc., to achieve the effects of reducing resistance, improving reaction effects, and improving operating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

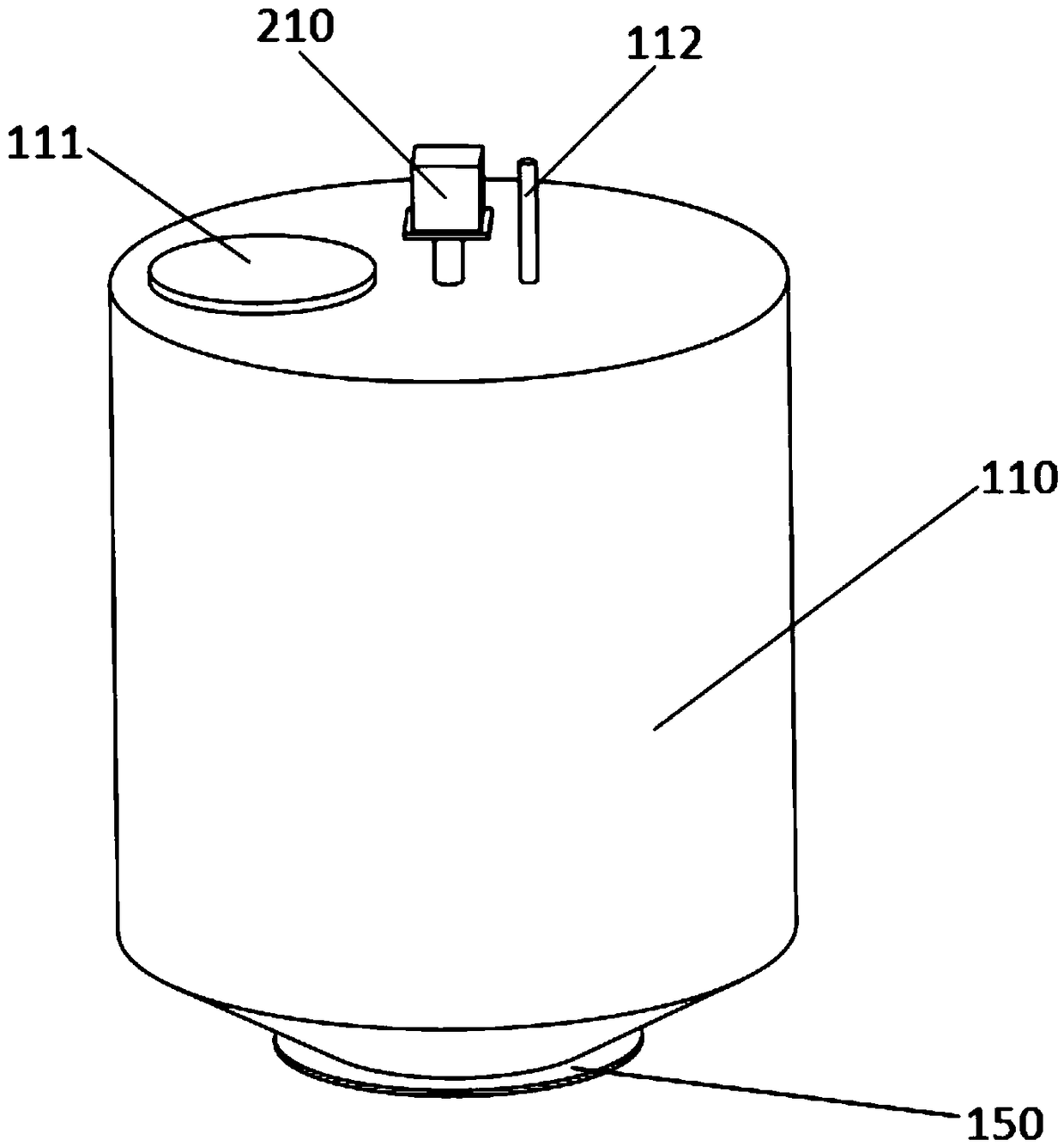

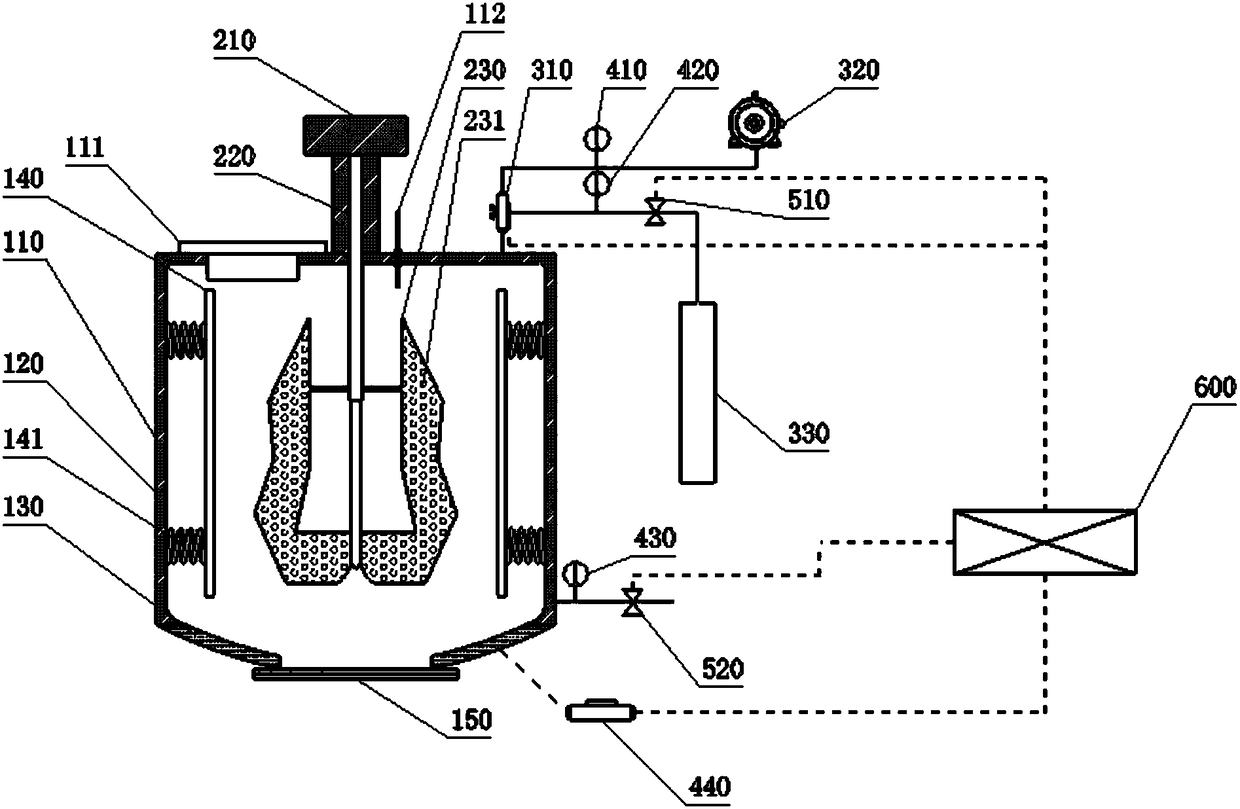

[0054] like figure 1 , figure 2 As shown, the present invention provides a polyacrylamide polymerization reactor, the main structure of which includes: reactor body 110, motor 210, rotating shaft 220, stirring paddle 230, vacuum pump 320, inert gas protection bottle 330, temperature sensor 440 and control device 600; wherein, the reactor body 110 is a cylindrical structure, the upper part of the reactor body 110 is provided with a feed port, and a feed port cover 111 is detachably installed at the feed port, and the bottom of the reactor body 110 is an arc shaped heating plate 130, a hopper 150 is set at the center of the arc-shaped heating plate 130, the reactor body 110 can communicate with the outside through the pressure relief valve 520, the motor 210 is detachably fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com