Deep treatment process and equipment of pharmaceutical waste water being stricter than class-A standards

A technology for advanced treatment of pharmaceutical wastewater, applied in multi-stage water treatment, natural water treatment, oxidized water/sewage treatment, etc., can solve the problems of complex effluent composition, poor biodegradability, and high chromaticity, to improve ozone oxidation efficiency, The effect of reducing clogging and reducing ozone consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

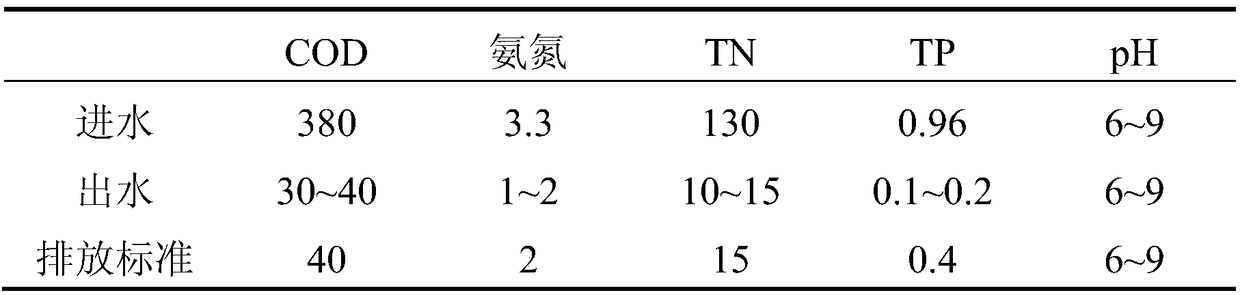

Embodiment 1

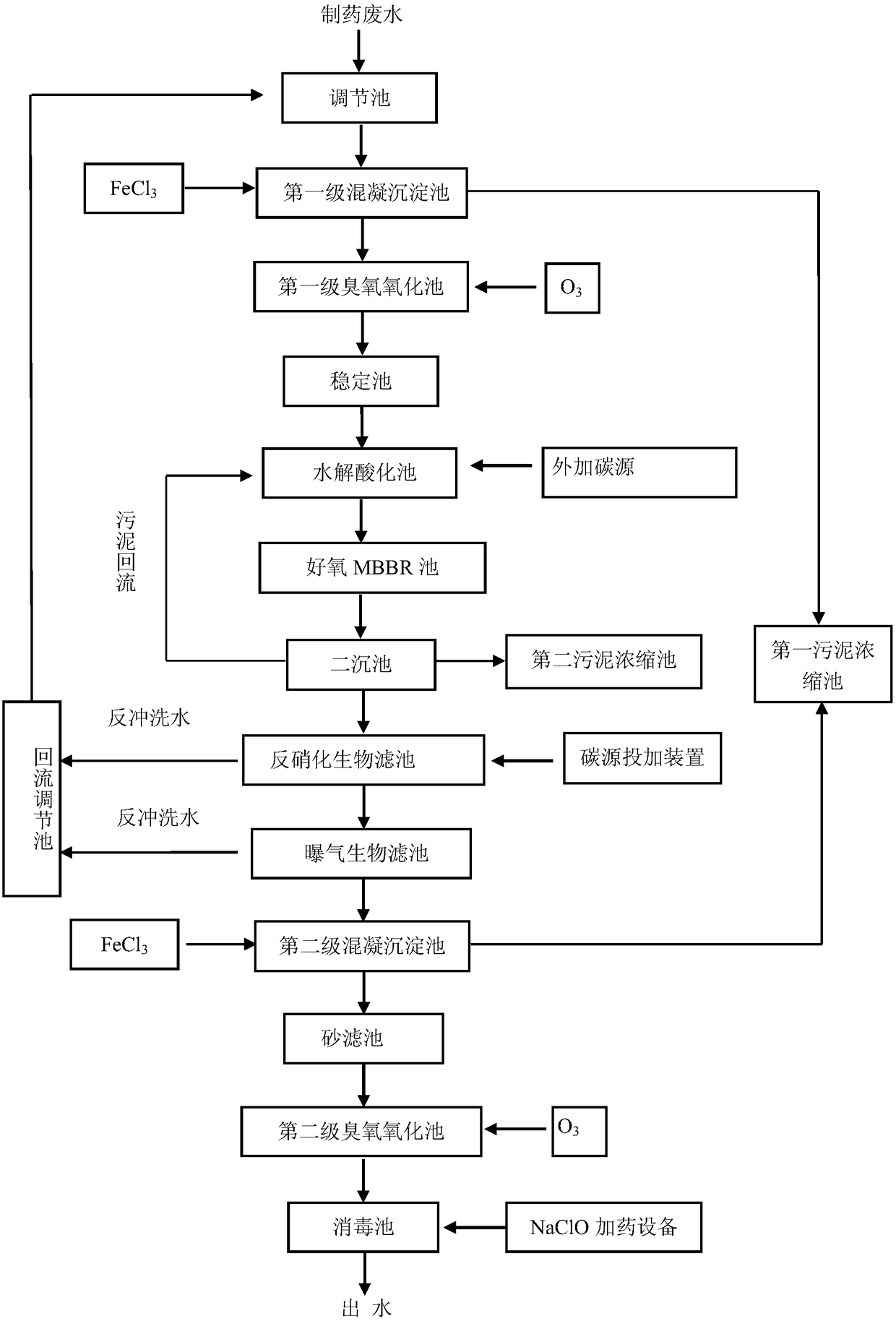

[0046] A method for advanced treatment of effluent water from sewage treatment stations of pharmaceutical factories in this embodiment, the process flow can be found in figure 1 , the specific steps are:

[0047] (1) The effluent from the wastewater treatment station of pharmaceutical companies enters the regulating tank through the pipeline for water volume and homogeneity adjustment, and then the wastewater enters the first-stage coagulation sedimentation tank, which adopts the form of inclined plate sedimentation tank, and the dosage of coagulant polymerized ferric chloride 60mg / L, can effectively remove most of the suspended matter, reduce the consumption of suspended matter on the ozone of the ozone oxidation system, improve the efficiency of ozone oxidation, and discharge the sludge from the coagulation sedimentation tank into the sludge concentration tank for concentration; Oxidation tank, ozone gas is passed into the ozone oxidation reaction tank, the dosage of ozone i...

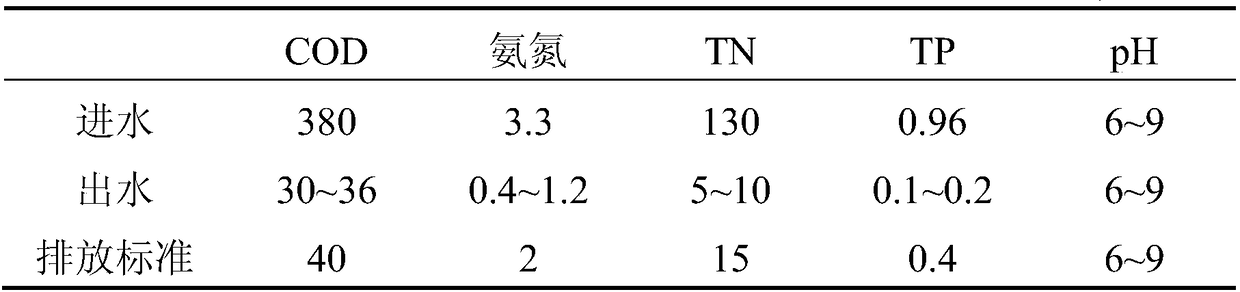

Embodiment 2

[0055] A method for advanced treatment of effluent water from sewage treatment stations of pharmaceutical factories in this embodiment, the process flow can be found in figure 1 , the specific steps are:

[0056] (1) The effluent from the wastewater treatment station of pharmaceutical companies enters the regulating tank through the pipeline for water volume and homogeneity adjustment, and then the wastewater enters the first-stage coagulation and sedimentation tank. The pool sludge is discharged into the sludge thickening tank for concentration; the effluent enters the first-stage ozone oxidation tank, and ozone gas is passed into the ozone oxidation reaction tank. The ozone dosage is 200mg / L, and the hydraulic retention time for the ozone oxidation reaction is for 30min. The top of the reactor is equipped with a tail gas destroyer to remove the remaining ozone in the tail gas, and the effluent enters the stabilization tank to remove the residual ozone in the water.

[0057...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com