Green activated soybean-meal protein and preparation method thereof

A soybean meal and protein technology, applied in the field of soybean meal protein, can solve the problems of uneven protein raw material particles, uneven distribution of cross-linked structure, low protein reactivity, etc., and achieve high product reactivity, no harmful substance release, and high reactivity high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

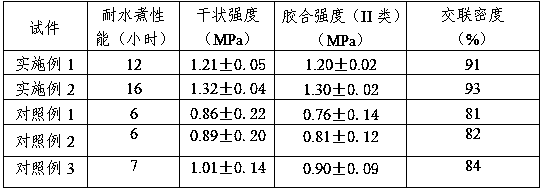

Examples

Embodiment 1

[0024] Example 1

[0025] This embodiment provides a method for preparing activated soybean meal protein, and the adhesive is prepared according to the following weight ratio:

[0026] Demineralized water 70 kg

[0027] Defatted Soy Protein Powder 25 kg

[0028] Ethanol 5.0kg

[0029] Nano calcium carbonate 0.2kg

[0031] Among them, defatted soy protein powder with a protein content of more than 52% was purchased from Huifu Grain and Oil Co., Ltd.; other materials were purchased from Beijing Chemical Reagent Co., Ltd.

[0032] This embodiment also provides the preparation method of the above-mentioned adhesive, and the specific preparation steps are as follows:

[0033] (1) Weigh each component according to the weight ratio, evenly disperse the protein powder, potassium chloride, and ethanol in the dispersion medium water, heat the water bath to 40°C and stir for 20 minutes;

[0034] (2) Add nano-calcium carbonate to the mixture obtained ...

Embodiment 2

[0037] This embodiment provides a method for preparing activated soybean meal protein, and the adhesive is prepared according to the following weight ratio:

[0038] Demineralized water 65 kg

[0039] Defatted Soy Protein Powder 25 kg

[0040] Ethanol 10kg

[0041] Nano calcium carbonate 0.4kg

[0042] Potassium chloride 2kg

[0043] Among them, defatted soy protein powder with a protein content of more than 52% was purchased from Huifu Grain and Oil Co., Ltd.; other materials were purchased from Beijing Chemical Reagent Co., Ltd.

[0044] The preparation method of the adhesive described in this embodiment is the same as that in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bonding strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com