A method for preparing magnetic metal nanotubes by pulse electrodeposition

A magnetic metal nanometer, pulse electrodeposition technology, applied in nanotechnology, metal material coating process, electrolytic coatings, etc., can solve the problems of inability to prepare high-quality magnetic metal nanotubes, cost, inability to control the length and diameter of nanotubes, etc. To achieve the effect of being conducive to mass production and preparation, low cost and low purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

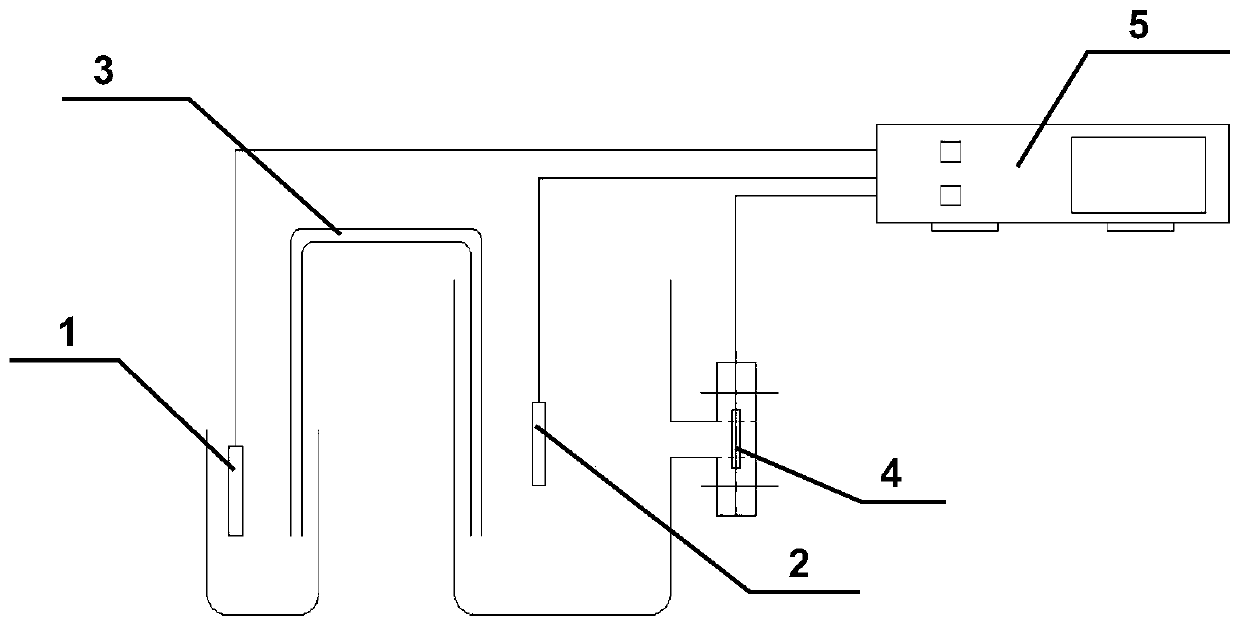

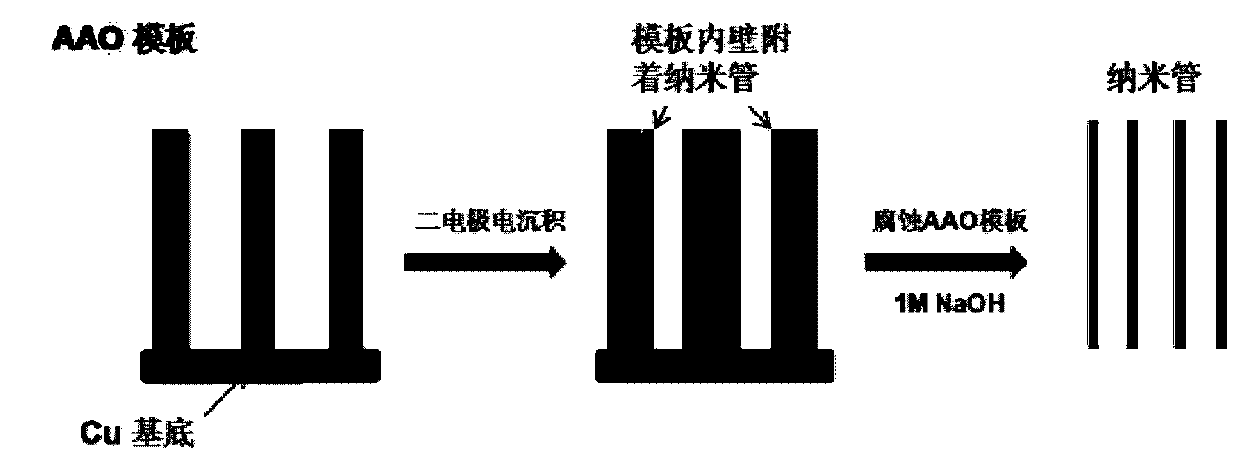

[0046] A method for preparing magnetic metal nanotubes by pulse electrodeposition. The method for preparing magnetic metal nanotubes by pulse electrodeposition includes the following steps:

[0047] (A) Template preparation

[0048] (A-1) Primary oxidation: The aluminum sheet is annealed at 500℃ for 4 hours, then sonicated in acetone for 10 minutes, then immersed in a 5wt% sodium hydroxide aqueous solution for 5 minutes, sonicated in acetone for 3 minutes, and then subjected to pretreatment. The treated aluminum flakes are placed in a 0.3mol / L oxalic acid aqueous solution, and electrochemically corroded for 4 hours at a voltage of 40V and a temperature of 0℃ to obtain primary alumina flakes;

[0049] (A-2) Removal of primary oxide film: take the primary alumina flake prepared in step (a-1) and place it in a mixed aqueous solution of phosphoric acid and chromic acid with a phosphoric acid concentration of 6 wt% and a chromic acid concentration of 1.5 wt% at 65°C Soaked in water for 1...

Embodiment 2

[0059] A method for preparing magnetic metal nanotubes by pulse electrodeposition. The method for preparing magnetic metal nanotubes by pulse electrodeposition includes the following steps:

[0060] (A) Template preparation

[0061] (A-1) Primary oxidation: The aluminum sheet is annealed at 500℃ for 4 hours, then sonicated in acetone for 10 minutes, then immersed in a 5wt% sodium hydroxide aqueous solution for 5 minutes, sonicated in acetone for 3 minutes, and then subjected to pretreatment. The treated aluminum flakes are placed in a 0.3mol / L oxalic acid aqueous solution, and electrochemically corroded for 4 hours at a voltage of 40V and a temperature of 0℃ to obtain primary alumina flakes;

[0062] (A-2) Removal of primary oxide film: take the primary alumina flake prepared in step (a-1) and place it in a mixed aqueous solution of phosphoric acid and chromic acid with a phosphoric acid concentration of 6 wt% and a chromic acid concentration of 1.5 wt% at 65°C Soaked in water for 1...

Embodiment 3

[0072] A method for preparing magnetic metal nanotubes by pulse electrodeposition. The method for preparing magnetic metal nanotubes by pulse electrodeposition includes the following steps:

[0073] (A) Template preparation

[0074] (A-1) Primary oxidation: The aluminum sheet is annealed at 500℃ for 4 hours, then sonicated in acetone for 10 minutes, then immersed in a 5wt% sodium hydroxide aqueous solution for 5 minutes, sonicated in acetone for 3 minutes, and then subjected to pretreatment. The treated aluminum flakes are placed in a 0.3mol / L oxalic acid aqueous solution, and electrochemically corroded for 4 hours at a voltage of 40V and a temperature of 0℃ to obtain primary alumina flakes;

[0075] (A-2) Removal of primary oxide film: take the primary alumina flake prepared in step (a-1) and place it in a mixed aqueous solution of phosphoric acid and chromic acid with a phosphoric acid concentration of 6 wt% and a chromic acid concentration of 1.5 wt% at 65°C Soaked in water for 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com