Medical first aid rapid condensation hemostatic gauze and preparation method thereof

A kind of hemostatic gauze, fast technology, applied in the field of medical emergency materials, can solve problems such as unfavorable hemostasis, increased pain, blood-sucking, poor hemostatic effect, etc., to achieve the effect of improving blood-sucking and hemostasis, and relieving pain.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

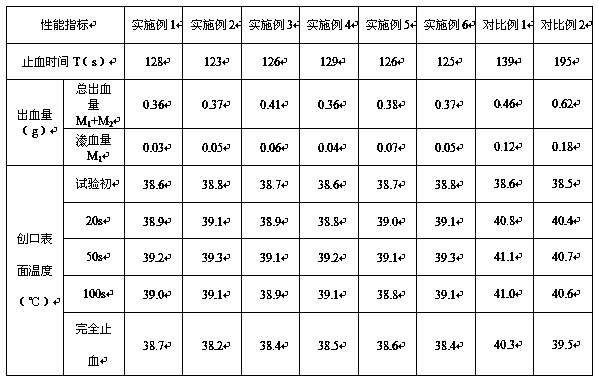

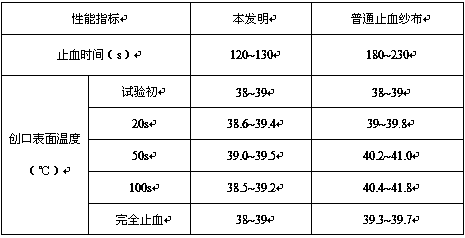

Examples

Embodiment 1

[0035] (1) Immerse the yarn in an aqueous solution of acrylamide, add an initiator under the protection of nitrogen, and generate polyacrylamide by initiating polymerization, so that the polyacrylamide is completely covered on the inner and outer surfaces of the yarn; among them: yarn 82.2 parts by weight , 17 parts by weight of acrylamide, 0.8 parts by weight of initiator; the yarn is absorbent cotton yarn; the initiator is potassium sulfate; the temperature of the polymerization reaction is 42°C;

[0036] (2) Add a foaming agent, heat and dry, and loosen the polyacrylamide through the foaming agent; wherein: 98 parts by weight of polyacrylamide-coated yarn, 2 parts by weight of the foaming agent; the foaming agent is n-pentyl alkyl;

[0037] (3) The yarn is spun to obtain a gauze loaded with loose polyacrylamide; the warp and weft density of the gauze is 40 threads / inch, and the grammage is 70g / m 2 ;

[0038] (4) Mix nonanol, n-pentadecane, and graphene evenly to make a ph...

Embodiment 2

[0043](1) Immerse the yarn in an aqueous solution of acrylamide, add an initiator under the protection of nitrogen, and generate polyacrylamide by initiating polymerization, so that the polyacrylamide is completely coated on the inner and outer surfaces of the yarn; among them: 84.5 parts by weight of yarn , 15 parts by weight of acrylamide, 0.5 parts by weight of an initiator; the yarn is an ultra-high molecular weight polyethylene yarn; the initiator is potassium sulfate; the temperature of the polymerization reaction is 35° C.;

[0044] (2) Add a foaming agent, heat and dry, and loosen the polyacrylamide through the foaming agent; wherein: 97 parts by weight of polyacrylamide-coated yarn, 3 parts by weight of the foaming agent; the foaming agent is n-hexane ;

[0045] (3) The yarn is spun to obtain a gauze loaded with loose polyacrylamide; the warp and weft density of the gauze is 30 threads / inch, and the grammage is 60g / m 2 ;

[0046] (4) Mix nonanol, n-pentadecane, and ...

Embodiment 3

[0051] (1) Immerse the yarn in an aqueous solution of acrylamide, add an initiator under the protection of nitrogen, and generate polyacrylamide by initiating polymerization, so that the polyacrylamide is completely coated on the inner and outer surfaces of the yarn; among them: yarn 79 parts by weight , 20 parts by weight of acrylamide, 1 part by weight of initiator; the yarn is absorbent cotton yarn; the initiator is potassium sulfate; the temperature of the polymerization reaction is 45°C;

[0052] (2) Add a foaming agent, heat and dry, and loosen polyacrylamide through the foaming agent; wherein: 99 parts by weight of polyacrylamide-coated yarn, 1 part by weight of foaming agent; the foaming agent is n-heptyl alkyl;

[0053] (3) The gauze loaded with loose polyacrylamide is obtained by weaving the yarn; the warp and weft density of the gauze is 50 threads / inch, and the grammage is 90g / m 2 ;

[0054] (4) Mix nonanol, n-pentadecane, and graphene evenly to make a phase-chan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gram weight | aaaaa | aaaaa |

| Gram weight | aaaaa | aaaaa |

| Gram weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com