Compound desulfurizer and sulfurous gas deep desulfurization method

A desulfurization agent and gas technology, applied in the field of deep desulfurization of sulfur-containing gases, can solve the problems of low catalyst timeliness, large pipeline investment, high anti-corrosion costs, etc., achieve low absorption rate, realize direct emission, and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

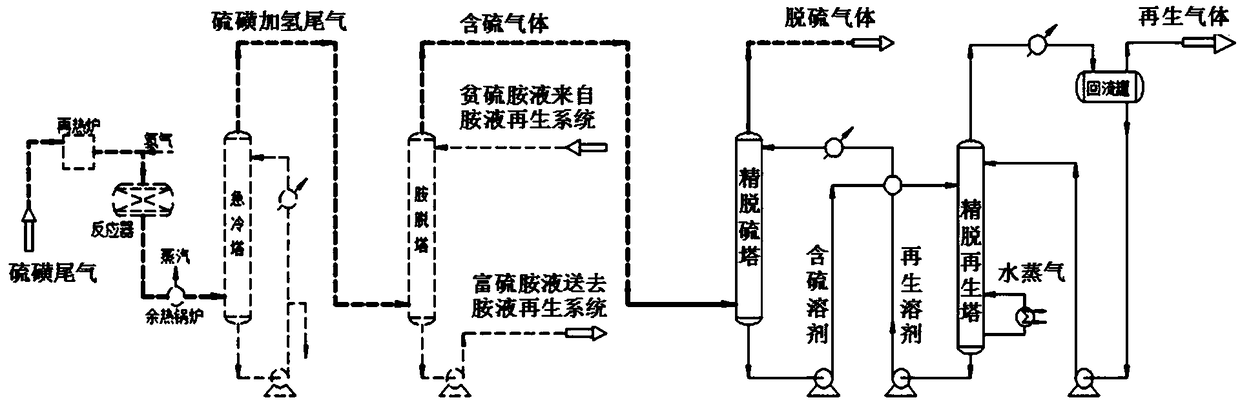

[0061] This embodiment provides a deep desulfurization method for sulfur-containing gas, wherein the sulfur-containing gas comes from the product of sulfur tail gas desulfurized by the SCOT process. The specific process of SCOT process desulfurization is carried out according to the above steps 1 to 5, and the specific process of deep desulfurization is carried out according to the above steps 6 to 8.

[0062] See Table 1 for specific process parameters of SCOT process desulfurization and deep desulfurization. Wherein, the component weight percent of the composite desulfurizer used in step 6 is: methyl sulfolane: 30%, MDEA: 20%, N-formylmorpholine: 30%, isopropanol: 10%, water: 10%.

[0063] The components of the sulfur hydrogenation tail gas obtained in step 2, the sulfur-containing gas obtained in step 5, and the desulfurized gas obtained by deep desulfurization of the sulfur-containing gas are shown in Table 2.

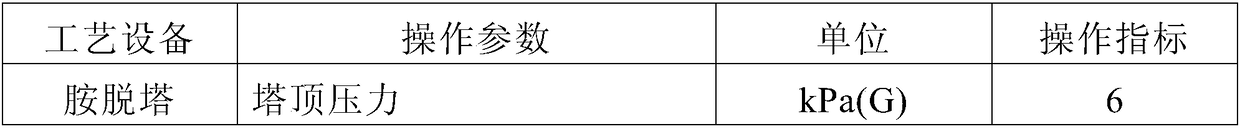

[0064] Table 1

[0065]

[0066]

[0067] Table 2

...

experiment example 1

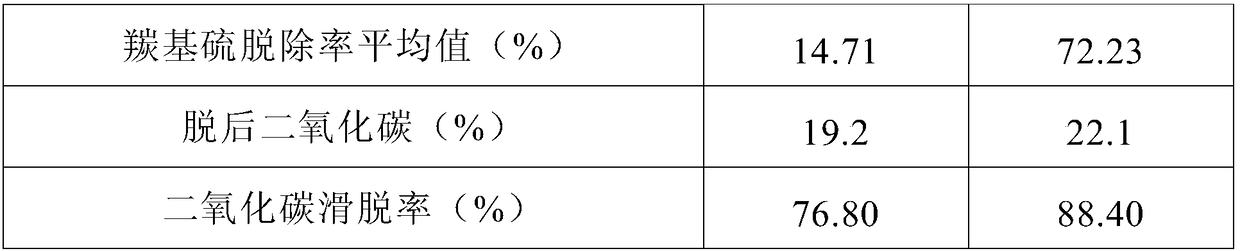

[0076] Composite desulfurizer used in Example 1 is compared with MDEA desulfurizer (30% MDEA aqueous solution) in the laboratory evaluation device for performance comparison, see Table 4 for specific comparison results.

[0077] Table 4

[0078]

[0079]

[0080] Note: The data in Table 4 are all measured under static absorption test conditions.

[0081] The comparison results in Table 4 show that the hydrogen sulfide removal effect of the composite desulfurizer is similar to that of the MDEA desulfurizer, but the removal rate of COS is 4.9 times that of the MDEA desulfurizer; With large sulfur capacity, the carbon dioxide slip rate is 11.6 percentage points higher than that of MDEA desulfurizer.

Embodiment 2

[0083] This embodiment provides a deep desulfurization method for sulfur-containing gas, wherein the sulfur-containing gas comes from the product of sulfur tail gas desulfurized by the SCOT process. The specific process of SCOT process desulfurization is carried out according to the above steps 1 to 5, and the specific process of deep desulfurization is carried out according to the above steps 6 to 8.

[0084] See Table 5 for specific process parameters of SCOT process desulfurization and deep desulfurization. Wherein, the component weight percent of the composite desulfurizer used in step 6 is: sulfolane: 20%, DIPA: 20%, N-methylpyrrolidone: 40%, 1,2-butanediol: 10%, water: 10% .

[0085] The components of the sulfur hydrogenation tail gas obtained in step 2, the sulfur-containing gas obtained in step 5, and the desulfurized gas obtained by deep desulfurization of the sulfur-containing gas are shown in Table 6.

[0086] table 5

[0087]

[0088]

[0089] Table 6

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com