Preparation method and application of polyamide-amine dendrimer polymer immobilized heteropoly acid catalyst

A polyamide and dendritic technology, which is used in the preparation of polyamide-amine dendritic polymer immobilized heteropolyacid catalysts, and the application field in oxidative desulfurization, can solve the problem of poor oxidative desulfurization effect, low surface area and porosity, and impurities. Problems such as poor compatibility between polyacid and oil phase, to achieve the effect of improved desulfurization efficiency, large specific surface area, and environmentally friendly production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

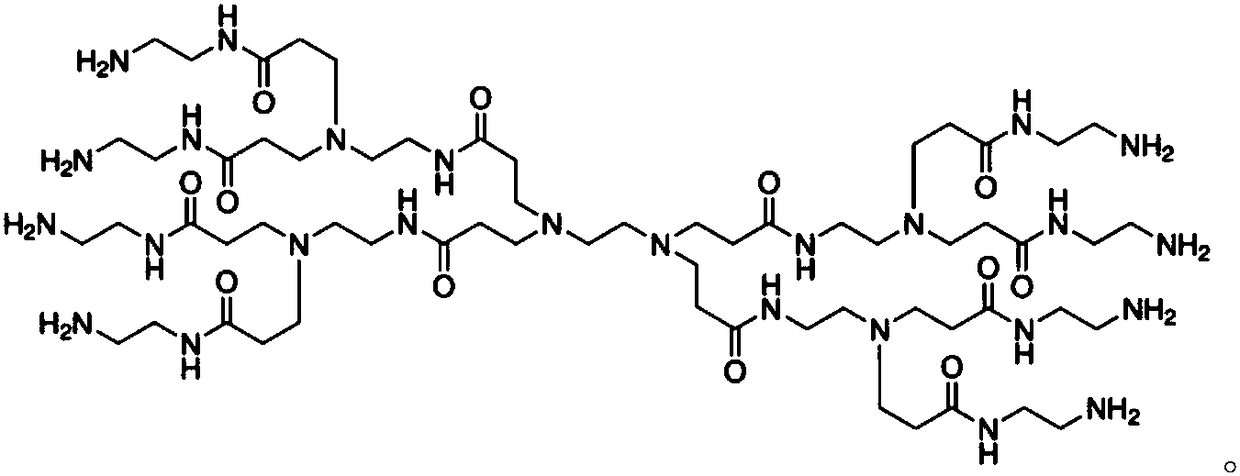

Image

Examples

Embodiment 1

[0024] Polyamide-amine dendrimer / H 3 PW 12 O 40 Preparation:

[0025] Add 2g of polyamide-amine dendrimer (generation 1) to 50ml of deionized water, stir for 2h, the temperature is 30 ℃; 3g heteropoly acid (H 3 PW 12 O 40 ) Dissolve in 30ml of deionized water to prepare a solution, and add the above polyamide-amine dendritic polymer solution dropwise, control the temperature at 30℃, stir vigorously for 2h, and separate by dialysis to obtain a polyamide-amine dendritic polymer. Molecularly fixed heteropoly acid catalyst.

Embodiment 2

[0027] Polyamide-amine dendrimer / H 3 PMo 12 O 40 Preparation:

[0028] 1.5g of polyamide-amine dendrimer (generation 2) was added to 40ml of deionized water, stirred for 3h, the temperature was 40℃; 2g of heteropolyacid (H 3 PMo 12 O 40 ) Dissolve in 20ml of deionized water to prepare a solution, and add the above polyamide-amine dendritic polymer solution dropwise, control the temperature at 50℃, stir vigorously for 3h, and separate by dialysis to obtain polyamide-amine dendritic polymer. Molecularly fixed heteropoly acid catalyst.

Embodiment 3

[0030] Polyamide-amine dendrimer / H 4 SiW 12 O 40 Preparation:

[0031] 1.5g of polyamide-amine dendrimer (generation number 3) was added to 40ml of deionized water, stirred for 3h, the temperature was 40 ℃; 2g heteropoly acid (H 4 SiW 12 O 40 ) Dissolve in 20ml of deionized water to prepare a solution, and add the above polyamide-amine dendritic polymer solution dropwise, control the temperature at 50℃, stir vigorously for 4h, and separate by dialysis to obtain polyamide-amine dendritic polymer. Molecularly fixed heteropoly acid catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com