A kind of preparation method of self-healing cement-based material

A cement-based material and self-healing technology, applied in the field of building materials, can solve the problems of limited self-healing ability and slow self-healing speed of self-healing concrete, shorten the self-healing time, promote self-polymerization, increase the The effect of bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

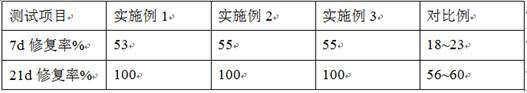

Examples

preparation example Construction

[0021] A preparation method of a self-healing cement-based material, the preparation method comprising the steps of:

[0022] (1) Grind calcium silicate and aluminum powder at 500r / min for 70 minutes according to the mass ratio of 1:3~5, use nitrogen for protection during the grinding process, collect the ground material, and mix the ground material and the mixture Put it into an ultrasonic vibrator at a mass ratio of 1:4 for 20 minutes of ultrasonic vibration, collect the vibrator, and set aside;

[0023] (2) Put the clay, surfactant and ethanol solution into the ball mill at a mass ratio of 4 to 6:1:3 to 5, then add steel balls with a diameter of 60mm that are 5 to 6 times the mass of clay, and run at 600r / min Ball milling for 1 hour, during the ball milling process, the temperature inside the ball mill is not higher than 40°C, collect the ball milled material, filter, and collect the filter residue;

[0024] (3) In parts by weight, take 80-90 parts of 1.2mol / L ethanol solu...

Embodiment 1

[0028] The mixture is prepared by heating ethanol and pine resin at a mass ratio of 1:2 at 50°C for 40 minutes to obtain the mixture.

[0029] The surfactant of choice is polyoxyethylene alkanolamide.

[0030] The choice of additive is furfural.

[0031] A preparation method of a self-healing cement-based material, the preparation method comprising the steps of:

[0032] (1) According to the mass ratio of 1:3, grind calcium silicate and aluminum powder at 500r / min for 70min, use nitrogen for protection during the grinding process, collect the ground material, and mix the ground material and the mixture by mass Ratio 1:4, put it into an ultrasonic vibrator for 20 minutes of ultrasonic vibration, collect the vibrator, and set aside;

[0033] (2) Put the clay, surfactant and ethanol solution into the ball mill according to the mass ratio of 4:1:3, then add steel balls with a diameter of 60mm that are 5 times the mass of clay, and perform ball milling at 600r / min for 1h. The te...

Embodiment 2

[0038] The mixture is prepared by heating ethanol and pine resin at a mass ratio of 1:2 at 55°C for 40 minutes to obtain the mixture.

[0039] The choice of surfactant is sodium dodecylbenzenesulfonate.

[0040] The choice of additive is furfural.

[0041] A preparation method of a self-healing cement-based material, the preparation method comprising the steps of:

[0042] (1) According to the mass ratio of 1:5, grind calcium silicate and aluminum powder at 500r / min for 70min, use nitrogen for protection during the grinding process, collect the ground material, and mix the ground material and the mixed solution by mass Ratio 1:4, put it into an ultrasonic vibrator for 20 minutes of ultrasonic vibration, collect the vibrator, and set aside;

[0043] (2) Put the clay, surfactant and ethanol solution into the ball mill at a mass ratio of 6:1:5, then add steel balls with a diameter of 60 mm that are 6 times the mass of clay, and perform ball milling at 600 r / min for 1 hour. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com