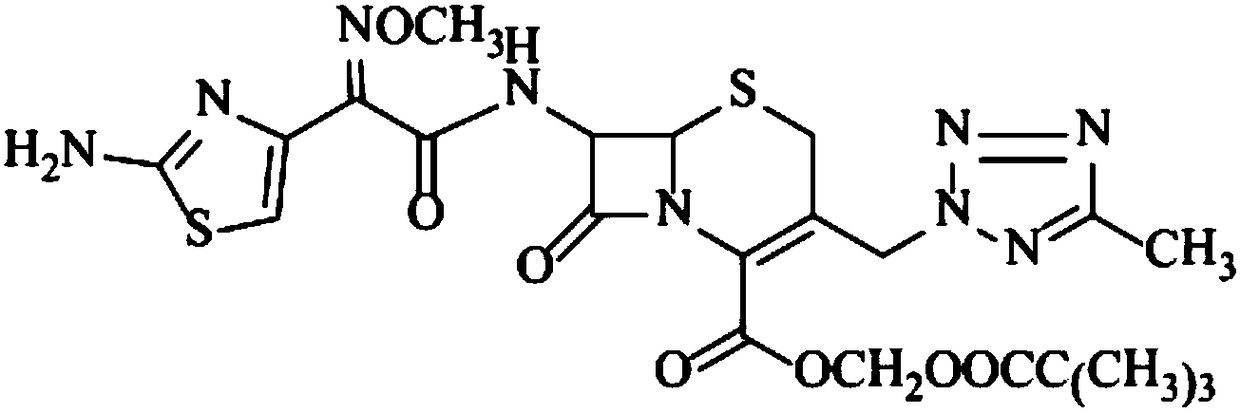

Preparation method of cefteram pivoxil

A technology for cefdram pivalate and methyl tetrazolium, which is applied in the field of preparation of cefdram pivoxil, can solve the problems of refining and removal, low product purity, easy generation of impurities and the like, and achieves mild reaction conditions, The effect of high product purity and stable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

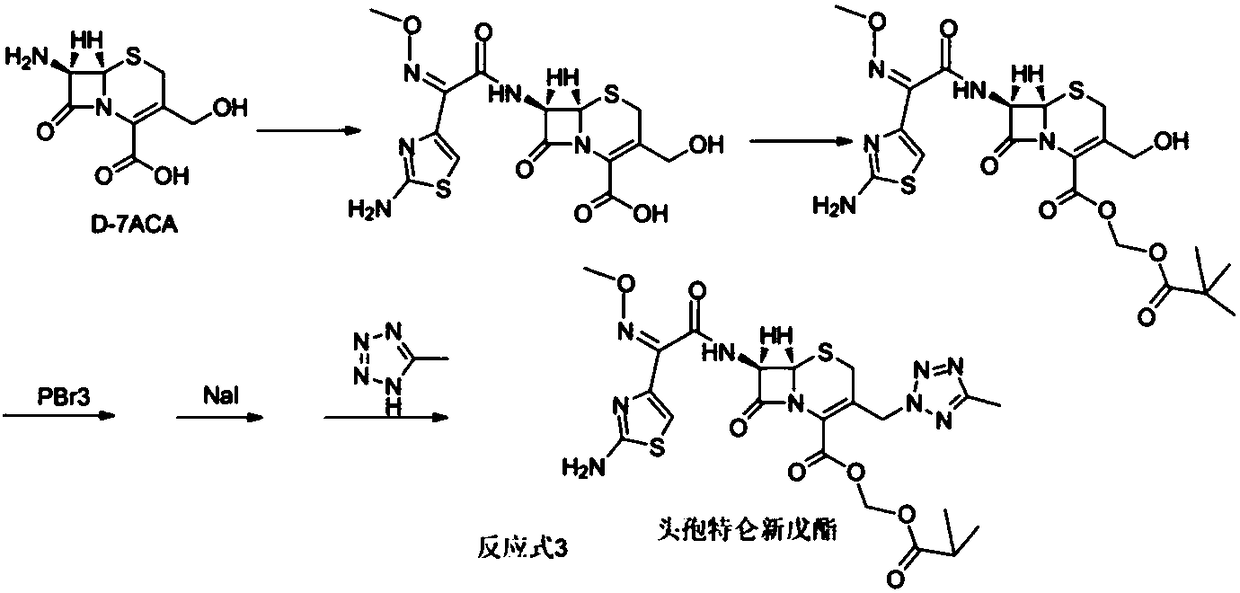

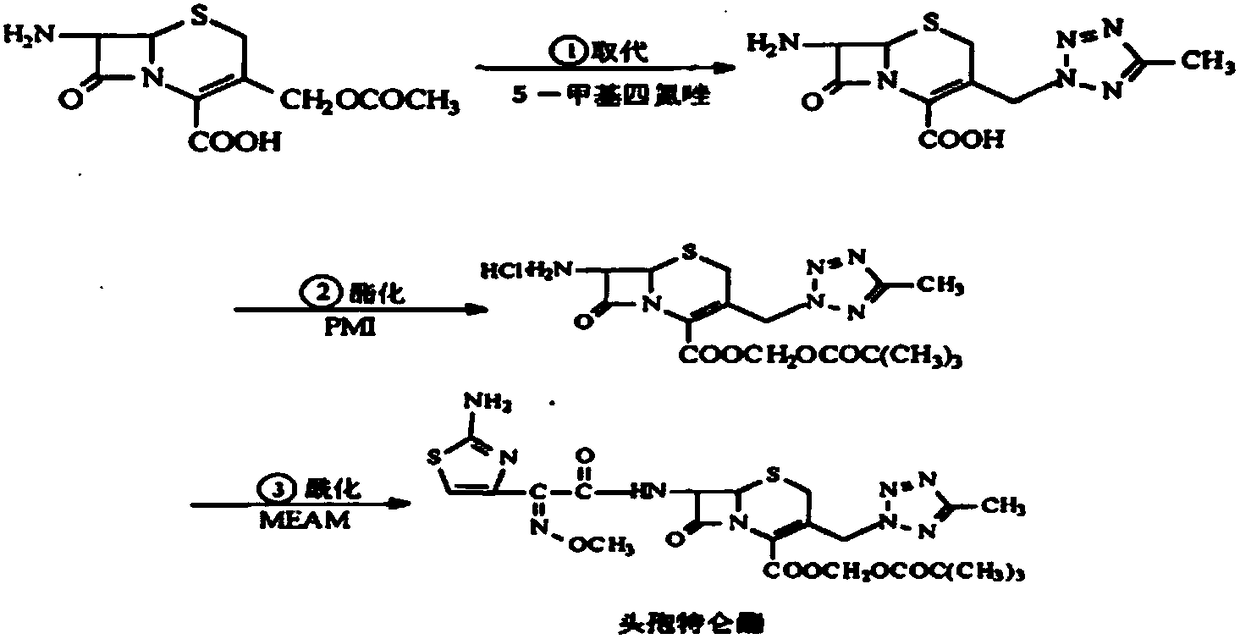

Method used

Image

Examples

Embodiment 1

[0033] Step 1) Slowly add 3.03g of 5-methyltetrazolium into 51mL of 60% H 2 SO 4 , stirred at room temperature for 20 minutes, 8.17 g of 7-ACA was added in three times, with an interval of 15 minutes between each addition, and the reaction was stirred at room temperature for 1 to 1.5 hours; ), and then the extract was washed with 40mL of water, 40mL (3%) Na 2 CO 3 Dissolved, washed with 40mL water, anhydrous Na 2 SO 4 After drying, the solvent was evaporated, and 7.87 g of 7-MTCA was obtained by vacuum drying, with a yield of 96.21%, a purity of 99.82%, and 7-MTCA isomer impurity of 0.02%.

[0034] Step 2) Prepare a trimethylaluminum hexane solution with a concentration of 2M at 5°C for subsequent use; 5.24g Boc 2 O. 4.58g of ethyl aminothiaxamate was slowly added to 50mL of dichloromethane, and stirred at room temperature for 2h. Gradually add 5.0mmol of N,N-dimethylethylenediamine, stir at room temperature for 30min, add 13mL of 2M trimethylaluminum hexane solution, st...

Embodiment 2

[0037] Step 1) Slowly add 2.52g of 5-methyltetrazolium into 40mL of 60% H 2 SO 4 , stirred at room temperature for 20 minutes, 8.17 g of 7-ACA was added in three times, with an interval of 15 minutes between each addition, and the reaction was stirred at room temperature for 1 to 1.5 hours; ), and then the extract was washed with 40mL of water, 40mL (3%) Na 2 CO 3 Dissolved, washed with 40mL water, anhydrous Na 2 SO 4 After drying, the solvent was evaporated, and 7.57 g of 7-MTCA was obtained by vacuum drying, with a yield of 91.84%, a purity of 99.05%, and 7-MTCA isomer impurities of 0.07%.

[0038] Step 2) Prepare a trimethylaluminum hexane solution with a concentration of 2M at 5°C for subsequent use; 4.80g Boc 2 O. 4.58g of ethyl aminothiaxamate was slowly added to 50mL of dichloromethane, and stirred at room temperature for 2h. Gradually add 5.0mmol of N,N-dimethylethylenediamine, stir at room temperature for 30min, add 10mL of a hexane solution of trimethylaluminum...

Embodiment 3

[0041] Step 1) Slowly add 3.28g of 5-methyltetrazolium into 59mL of 60% H 2 SO 4 , stirred at room temperature for 20 minutes, 8.17 g of 7-ACA was added in three times, with an interval of 15 minutes between each addition, and the reaction was stirred at room temperature for 1 to 1.5 hours; ), and then the extract was washed with 40mL of water, 40mL (3%) Na 2 CO 3 Dissolved, washed with 40mL water, anhydrous Na 2 SO 4 After drying, the solvent was evaporated, and 7.66 g of 7-MTCA was obtained by vacuum drying, with a yield of 93.22%, a purity of 99.37%, and 0.05% of 7-MTCA isomer impurity.

[0042] Step 2) Prepare a trimethylaluminum hexane solution with a concentration of 2M at 5°C for subsequent use; 5.67g Boc 2 O. 4.58g of ethyl aminothiaxamate was slowly added to 50mL of dichloromethane, and stirred at room temperature for 2h. Gradually add 5.0mmol of N,N-dimethylethylenediamine, stir at room temperature for 30min, add 16mL of 2M trimethylaluminum hexane solution, st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com