Silk protein scaffold material and preparation method thereof

A scaffold material, silk protein technology, applied in medical science, surgery, etc., can solve the problems of uncontrollable surface structure of porous scaffold pore wall, high hardness, unsuitable for endothelial cell proliferation and blood vessel formation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The invention provides a method for preparing a silk protein scaffold material, comprising:

[0031] A) concentrating the silk protein solution to obtain a concentrated solution, wherein the mass concentration of silk protein in the concentrated solution is 15% to 35%;

[0032] B) diluting and heat-treating the concentrated solution obtained in step A) to obtain a hydrogel, and the mass concentration of silk protein in the hydrogel is 0.2% to 0.6%;

[0033] C) Mix the concentrated solution obtained in step A) with the hydrogel obtained in step B) to obtain a mixed solution; adjust the pH value of the mixed solution, stir, freeze, and dry to obtain a scaffold material; the pH value is 3 to 4 .

[0034] The silk protein solution of the present invention is a silk protein solution prepared by a conventional method, preferably, the preparation method is specifically:

[0035] a) heating and degumming silk in sodium carbonate solution, washing with water, and drying to obt...

Embodiment 1

[0064] 50g silk in 0.5% Na 2 CO 3 Boil in the solution at 100°C for 60 minutes to remove sericin on the outside of the silk, rinse with deionized water, repeat the above operation 3 times, and then dry the silk at 60°C. 15 g of the degummed silk after the above treatment was weighed and dissolved in 100 mL of a LiBr solution with a mass concentration of 9.3 mol / L, and dissolved at 60° C. for 4 hours. Then use a dialysis bag with a molecular weight cut-off of 3500 to immerse in deionized water and dialyze for 3 days, during which the water is changed every two hours to remove LiBr in the solution, thereby obtaining a pure silk protein solution with a mass concentration of 6%.

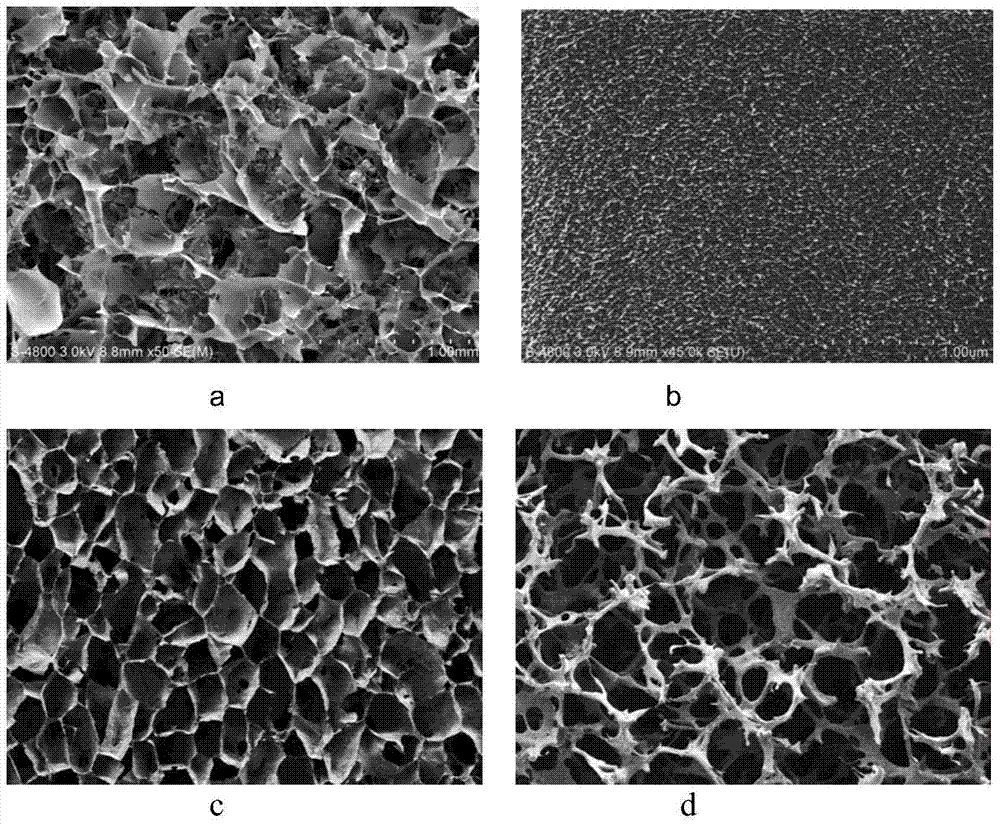

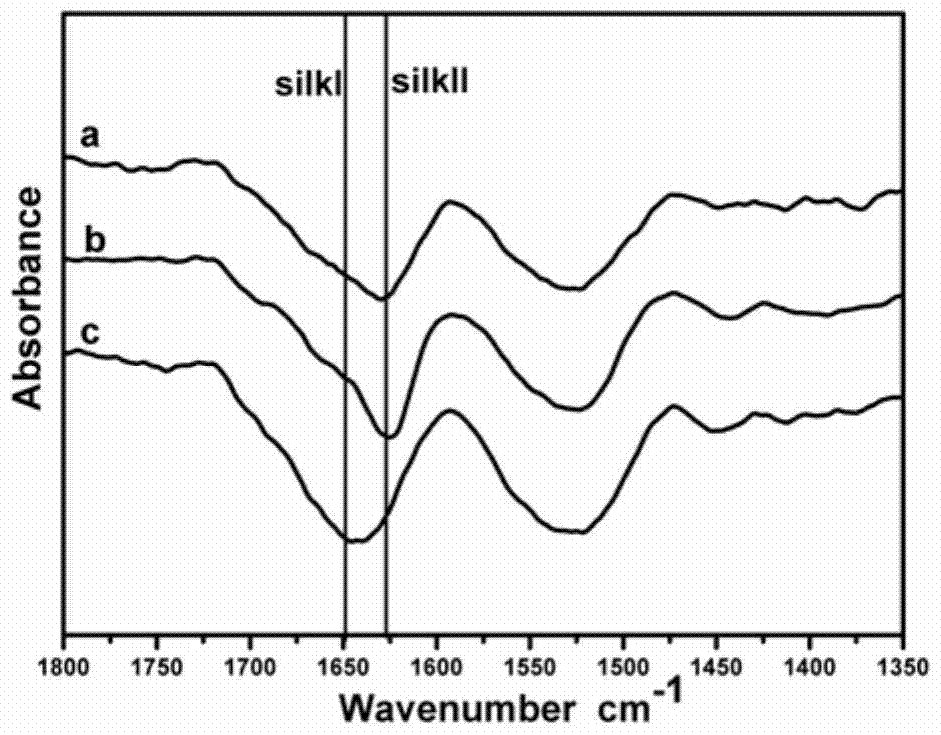

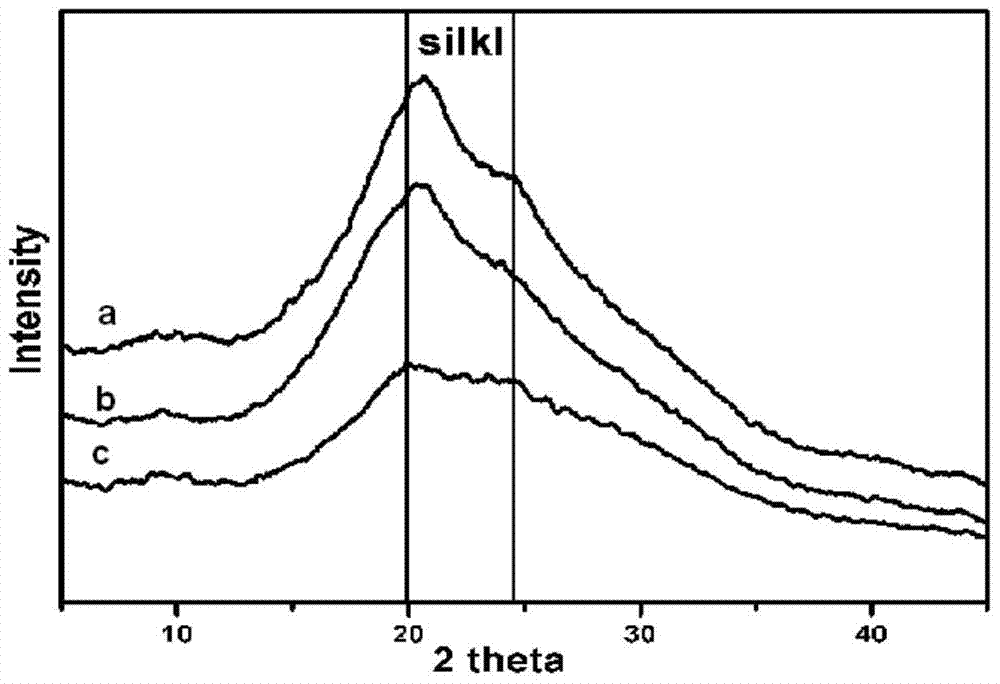

[0065] Concentrate the silk protein solution at 60° C. for 48 hours, put it in a fume hood and concentrate for 48 hours, and the mass concentration of the silk protein solution after concentration is 28%. Then the mass fraction of the silk protein aqueous solution was diluted to 0.3%, and then treated ...

Embodiment 2

[0088] 50g silk in 0.5% Na 2 CO 3 Boil in the solution at 100°C for 60 minutes to remove sericin on the outside of the silk, rinse with deionized water, repeat the above operation 3 times, and then dry the silk at 60°C. 15 g of the degummed silk after the above treatment was weighed and dissolved in 100 mL of a LiBr solution with a mass concentration of 9.3 mol / L, and dissolved at 60° C. for 4 hours. Then use a dialysis bag with a molecular weight cut-off of 3500 to immerse in deionized water and dialyze for 3 days, during which the water is changed every two hours to remove LiBr in the solution, thereby obtaining a pure silk protein solution with a mass concentration of 6%.

[0089] Concentrate the silk protein solution at 60° C. for 48 hours, put it in a fume hood and concentrate for 48 hours, and the mass concentration of the silk protein solution after concentration is 28%. Then the mass fraction of the silk protein aqueous solution was adjusted to 0.5%, and then treated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com