Organic solar cell and manufacturing method thereof

A solar cell and manufacturing method technology, applied in the directions of organic semiconductor devices, materials and circuits of organic semiconductor devices, etc., can solve the problems of ecological environment destruction, air quality decline, depletion of fossil energy, etc. The effect of the built-in electric field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

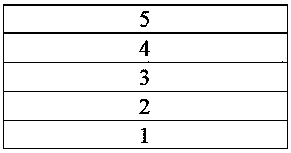

[0029] see figure 1 , the present invention provides a technical solution:

[0030] An organic solar cell, comprising an ITO glass substrate 1, a novel hole transport layer 2, an organic light absorbing layer 3, an electron transport layer 4 and a reflective electrode 5, wherein the novel hole transport layer is prepared by a solution method of MoO3 and fluorescent A composite hole transport layer of carbon dots, the thickness of the novel hole transport layer is 10 nm. The square resistance of the ITO glass substrate is less than 10 ohms, the visible light transmittance is greater than 90%, and the root mean square roughness of the ITO surface is less than 1 nm. The organic light-absorbing layer 3 is a P3HT:PC with donor-acceptor heterojunction structure 70 BM, the thickness of the organic light absorbing layer 3 is 50 nm. The electron transport layer 4 is Bphen, and the thickness of the electron transport layer 4 is 10 nm. The reflective electrode 5 is made of Al, and th...

Embodiment 2

[0044] An organic solar cell comprises an ITO glass substrate 1, a novel hole transport layer 2, an organic light absorbing layer 3, an electron transport layer 4 and a reflective electrode 5, and the described novel hole transport layer 2 is prepared by a solution method of MoO3 and A composite hole transport layer of fluorescent carbon dots, the thickness of the novel hole transport layer 2 is 50 nm. The square resistance of the ITO glass substrate 1 is less than 10 ohms, the visible light transmittance is greater than 90%, and the root mean square roughness of the ITO surface is less than 1 nm. The organic light absorbing layer 3 is a donor-receptor heterojunction structure C70: DPB, and the thickness of the organic light absorbing layer 3 is 60 nm. The electron transport layer 4 is LiF, and the thickness of the electron transport layer 4 is 1nm. The reflective electrode 5 is Ag, and the thickness of the reflective electrode is 1000 nm.

[0045] A method for manufacturing...

Embodiment 3

[0058] An organic solar cell comprises an ITO glass substrate 1, a novel hole transport layer 2, an organic light absorbing layer 3, an electron transport layer 4 and a reflective electrode 5, and the described novel hole transport layer 2 is prepared by a solution method of MoO3 and A composite hole transport layer of fluorescent carbon dots, the thickness of the novel hole transport layer 2 is 30 nm. The square resistance of the ITO glass substrate 1 is less than 10 ohms, the visible light transmittance is greater than 90%, and the root mean square roughness of the ITO surface is less than 1 nm. The organic light absorbing layer 3 is C60:SubPc with donor-acceptor heterojunction structure, and the thickness of the organic light absorbing layer 3 is 40 nm. The electron transport layer 4 is LiQ, and the thickness of the electron transport layer 4 is 2 nm. The reflective electrode 5 is Au, and the thickness of the reflective electrode 5 is 200 nm.

[0059] A method for manufac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com