Coated graphite lithium ion battery negative electrode material and preparation method thereof

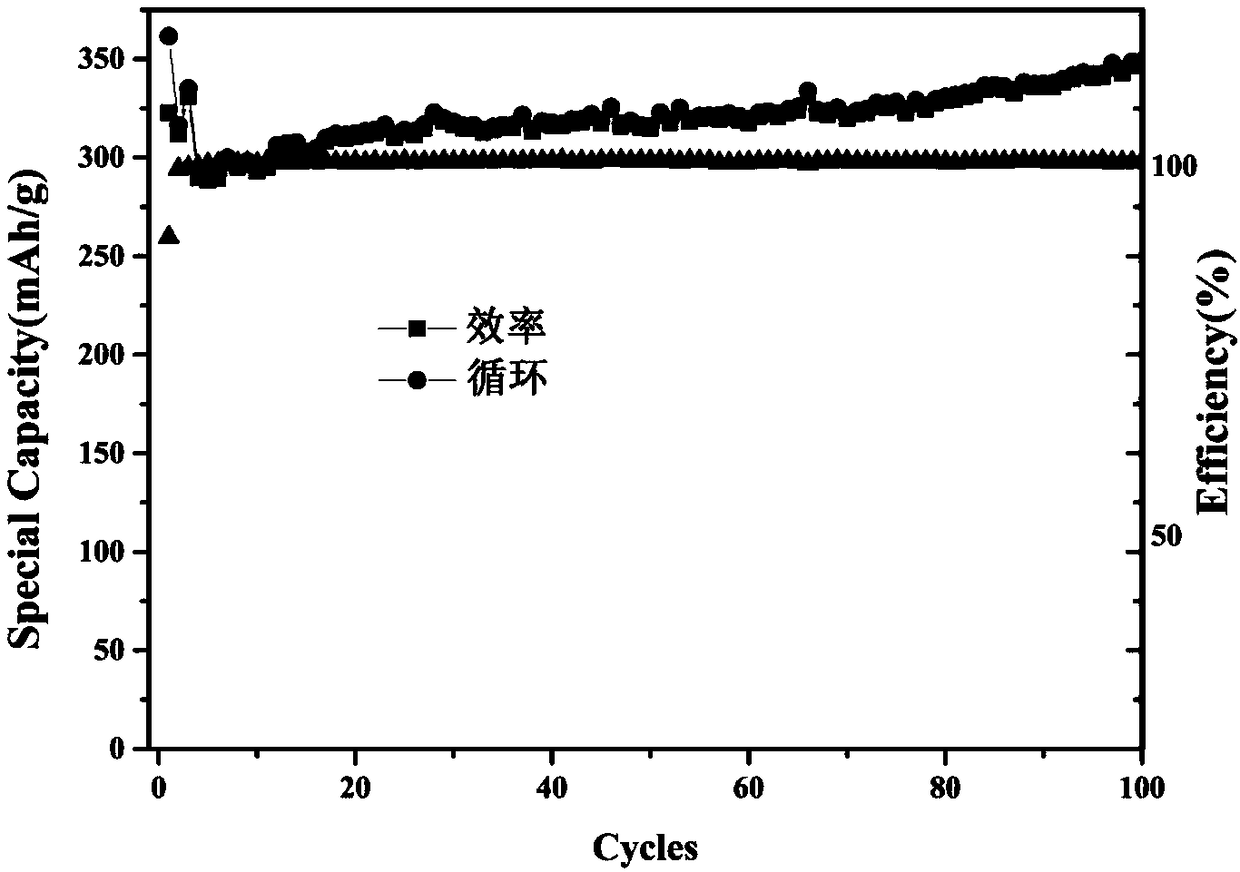

A technology of lithium ion battery and negative electrode material, applied in battery electrodes, batteries, secondary batteries, etc., can solve the problems of poor capacity retention rate and high working voltage of the whole battery, suppress the diffusion of oxygen vacancies, improve discharge capacity, reduce The effect of electrochemical internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

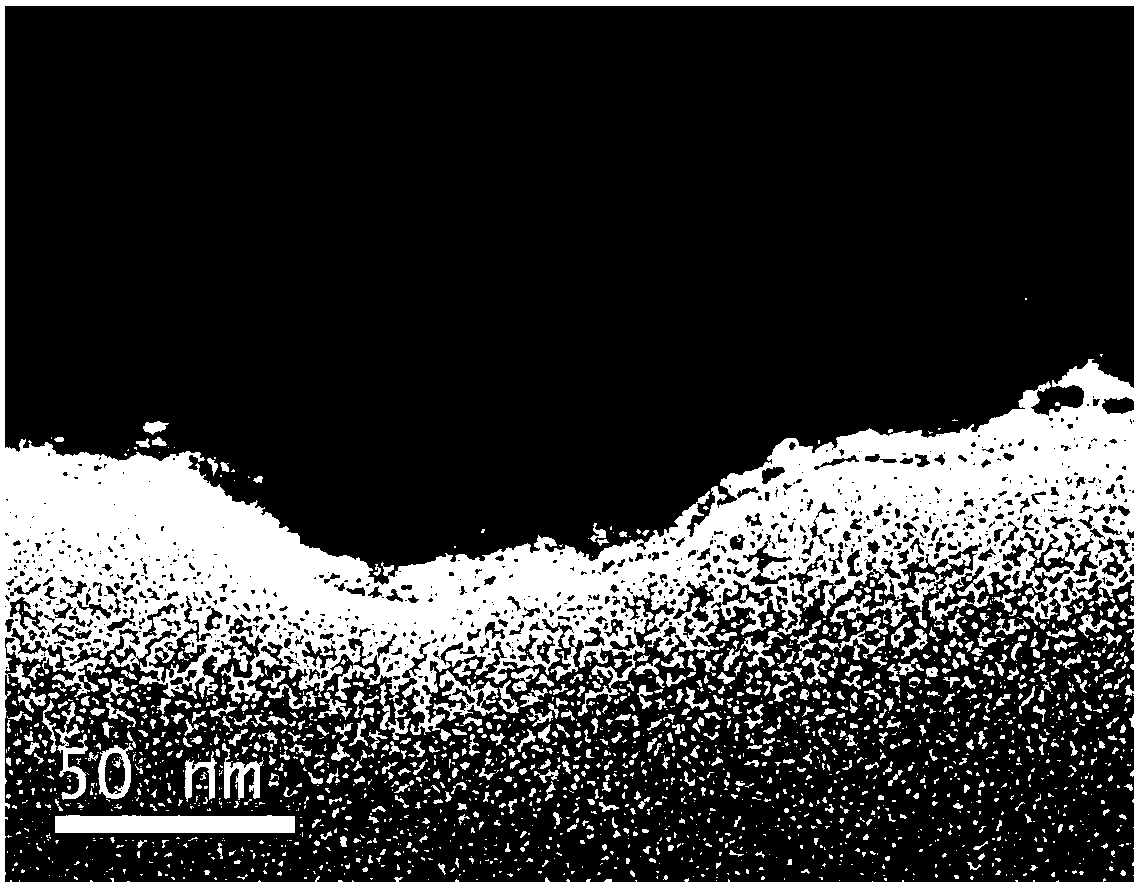

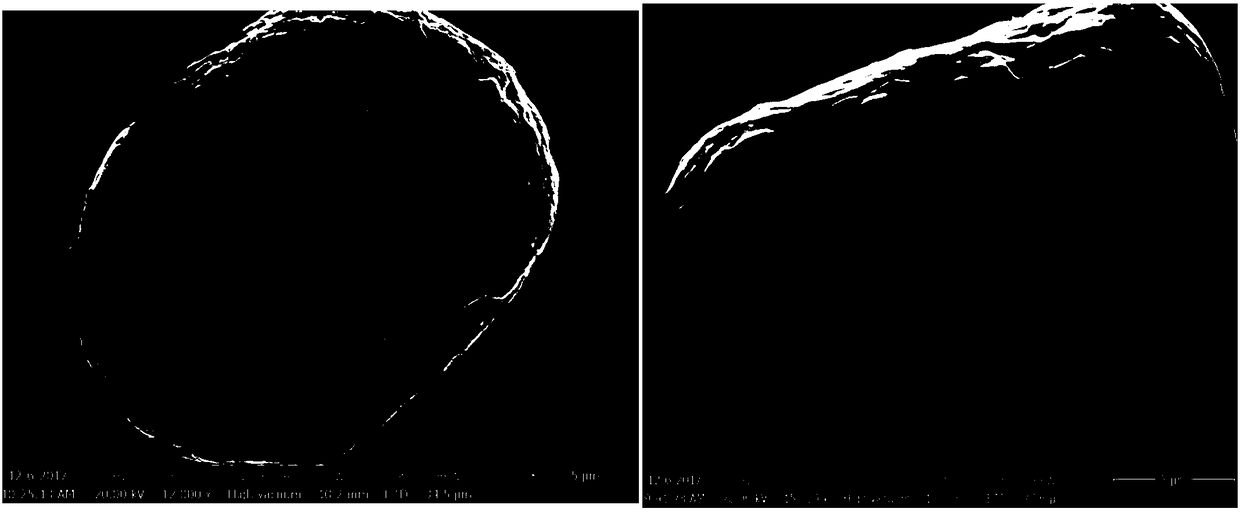

[0034] Embodiment 1: the preparation method of coated graphite lithium ion battery negative electrode material

[0035] Include the following steps:

[0036] (1) Pretreatment of graphite: disperse 0.6g artificial graphite in 100ml deionized water (the concentration of graphite dispersed in deionized water is 6g / L), add cationic surfactant cetyltrimethylammonium bromide ( CTAB) 0.02g, ultrasonic dispersion 30min obtains the dilute suspension of graphite;

[0037] (2) Precursor solution Al(OH) 3 Preparation: At a temperature of 20°C, 0.02g Al(NO 3 ) 3 9H 2 O dissolved in deionized water, and 0.2mol / L NH 3 ·H 2 The O solution was added dropwise into the three-necked flask at the same time, and by constant Al(NO 3 ) 3 9H 2The titration rate of the O solution is used to adjust the titration rate of the ammonia solution so as to regulate pH=7 (the rate of titration cannot be too fast to avoid the Al(OH) generated) 3 get together). The suspension was then aged for an addit...

Embodiment 2

[0047] Embodiment 2: the preparation method of coated graphite lithium ion battery negative electrode material

[0048] Include the following steps:

[0049] (1) Pretreatment of graphite: disperse 1g of artificial graphite in 100ml deionized water (the concentration of graphite dispersed in deionized water is 10g / L), add cationic surfactant dodecyl dimethyl benzyl ammonium chloride (1227) 0.05g, ultrasonic dispersion 30min obtains the dilute suspension of graphite;

[0050] (2) Precursor solution Al(OH) 3 Preparation: Dissolve 0.006833g aluminum sulfate octadecahydrate in deionized water at a temperature of 70°C, and 0.2mol / L NH 3 ·H 2 O solution is added dropwise in the there-necked flask simultaneously, adjusts the titration rate of ammonia solution so as to regulate pH=7 (the rate of addition can not be too fast, to avoid the Al(OH) of generation by the titration rate of constant aluminum sulfate solution 3 get together). The suspension was then aged for an additional ...

Embodiment 3

[0054] Embodiment 3: With reference to Example 2, the difference is that the quality of the cationic surfactant dodecyldimethylbenzyl ammonium chloride (1227) is 0.0009g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| cycle efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com