Aviation moisture separation device

A water-air separation and aviation technology, which is applied in measurement devices, separation methods, dispersed particle separation, etc., can solve the problems of cumbersome maintenance process for cleaning water cups, difficult to ensure the air tightness of products, and complicated gas path transfer structure, etc. Assembly manufacturability, air tightness, and simple structure and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

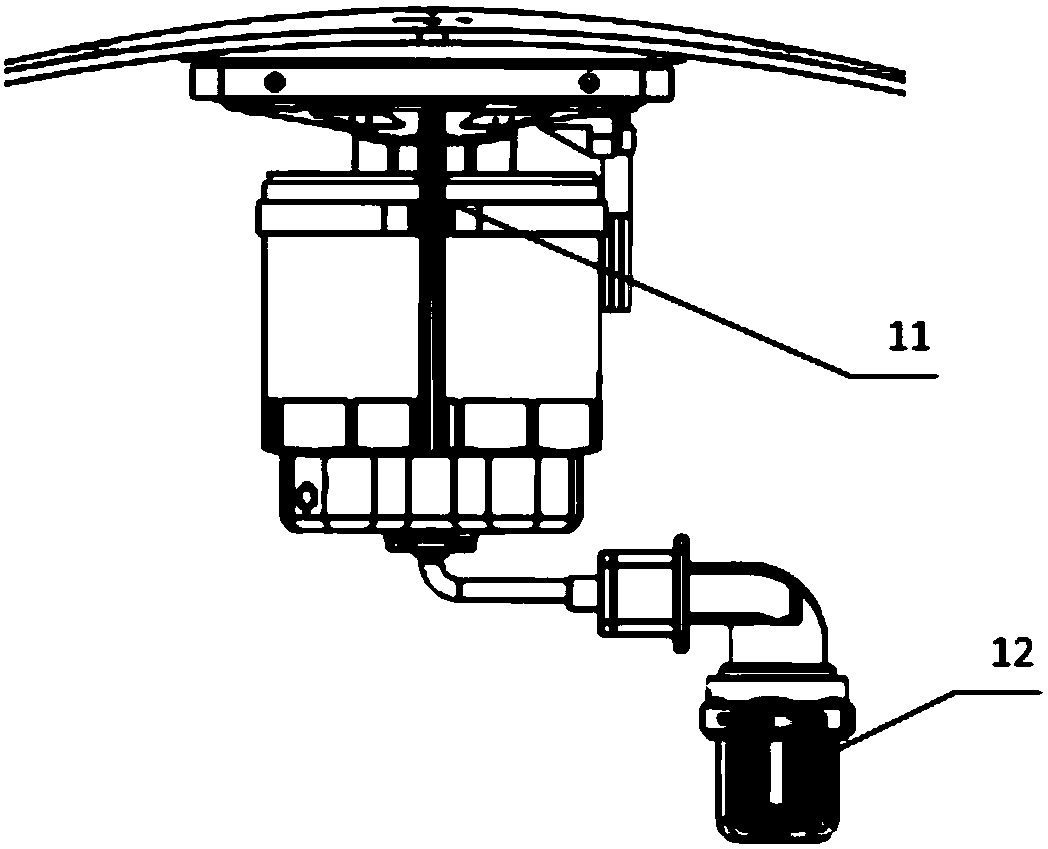

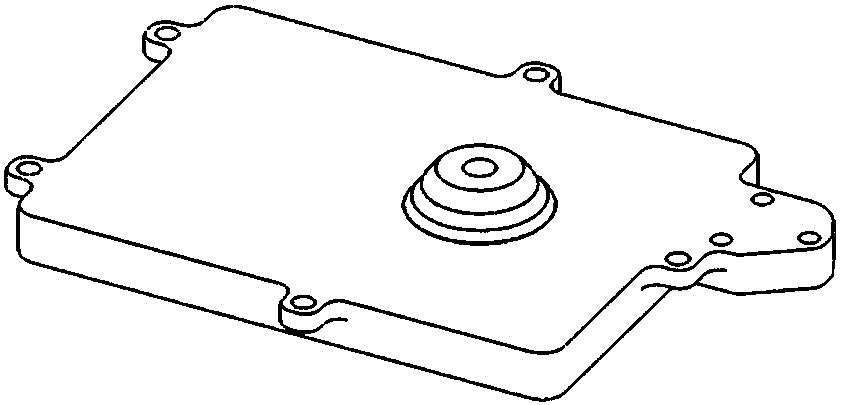

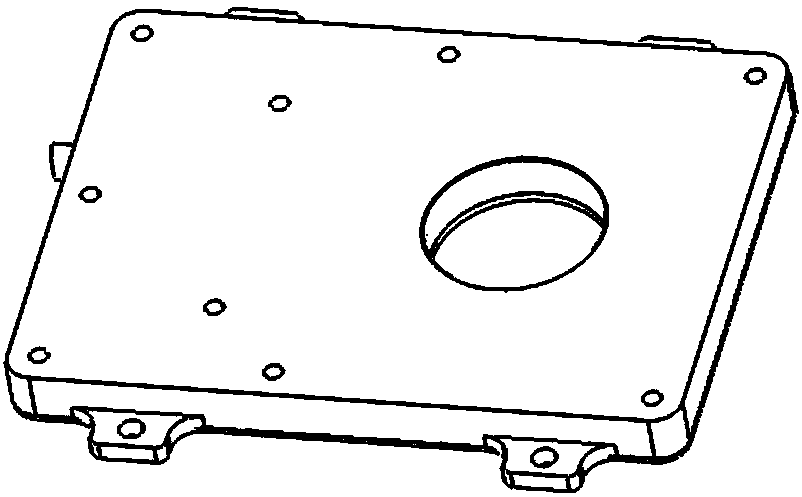

[0021] A kind of aviation water-gas separation device (see Figure 4 , Figure 5 , Figure 6 ), including the dewatering settler chamber 3 (see figure 2 ), water removal heater 2 (see image 3 ); the chamber 3 of the dewatering precipitator is a cavity structure, and the inlet and outlet of the gas source are set; the inlet of the gas source is arranged above the dewatering precipitator chamber 3, and the outlet of the gas source is higher than The bottom surface of the water-removing precipitator chamber 3 ensures that the inlet atmospheric condensed water will sink to the bottom of the chamber and will not enter the pipeline; the inlet of the gas source is communicated with the pressure measuring hole of the body pressure sensor sensing part 1; The outlet of the gas source communicates with the pressure sensor 4 inside the fuselage pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com