Application of a star-shaped compound carrying a dense charge as a flocculant

A compound and flocculant technology, applied in the application field of star compound as flocculant, can solve the problems of large amount of chemical flocculant, secondary pollution, difficult to decompose, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

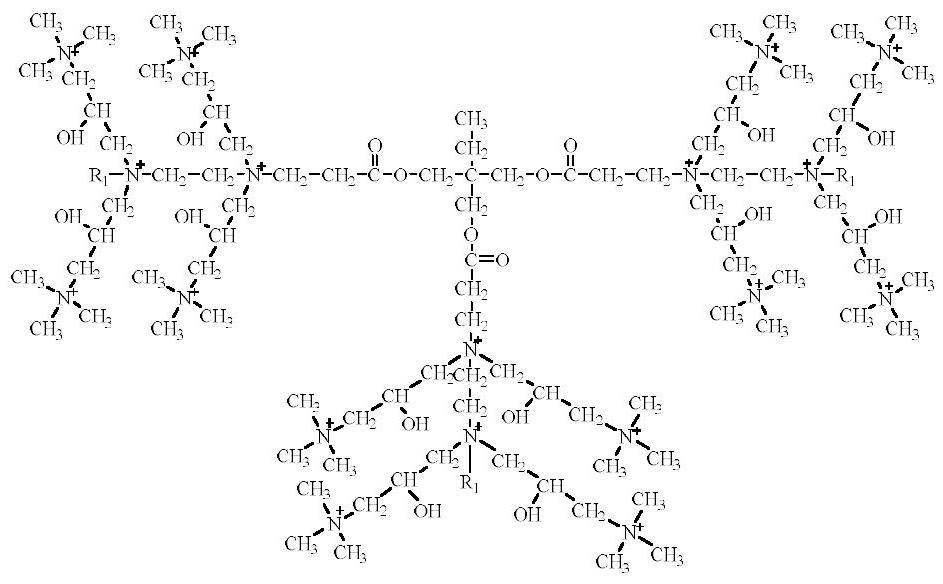

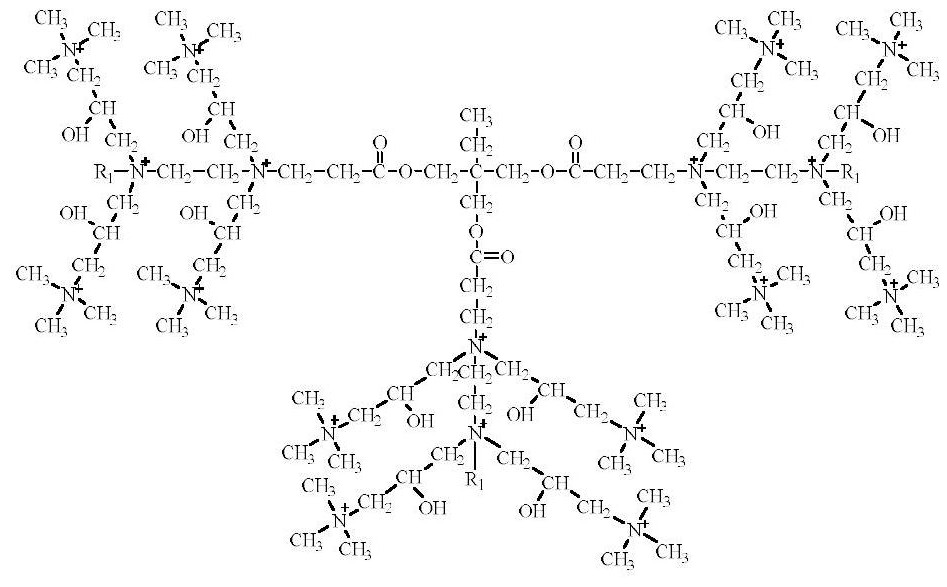

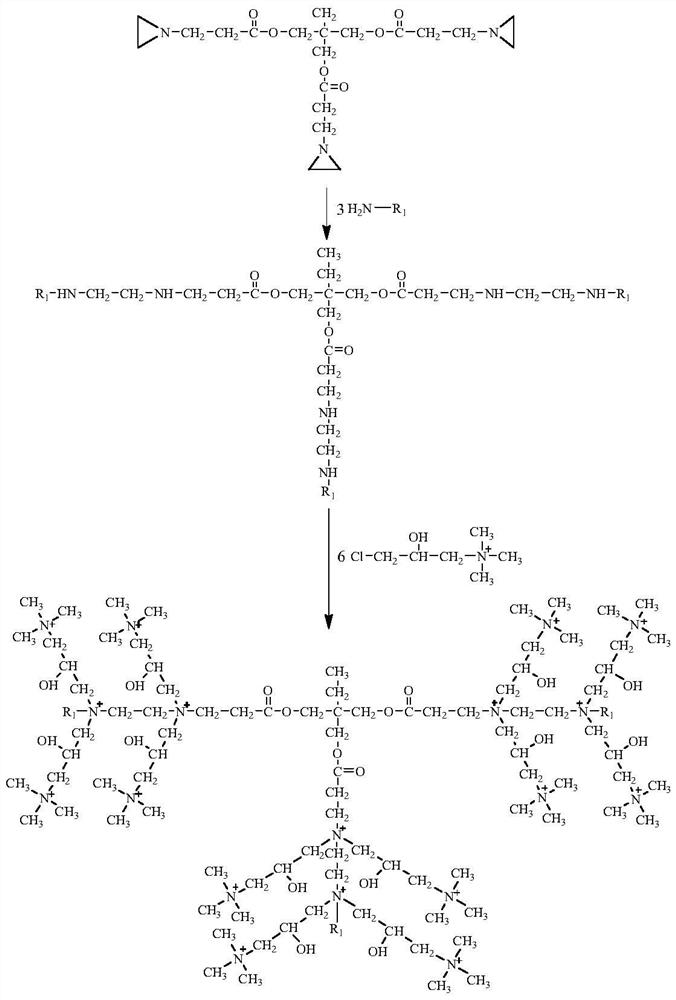

Method used

Image

Examples

Embodiment 1

[0029] (1) Be that 20% methylamine aqueous solution (23.25g, wherein contain methylamine 4.65g, 0.15mol) and acidic catalyst (85%H 3 PO 4 , 0.25g), warming up to 40 ° C, dropwise added a mass fraction of 70% trimethylolpropane-three (3- aziridinyl propionate) aqueous solution (35.42g, which contains trimethylolpropane-three (3-Aziridinyl propionate) 21.25 g, 0.05 mol), the dropping time is 40 min. After the dropwise addition, the temperature was raised to 50° C. for 7 h.

[0030] (2) The above reaction solution was mixed with K 2 CO 3 Adjust to weakly alkaline (pH=9~10), add dropwise 3-chloro-2-hydroxypropyl-trimethylammonium chloride aqueous solution (70.50g, containing 3-chloro-2- Hydroxypropyl-trimethylammonium chloride 56.40g, 0.30mol), dropwise time is 60min, and react at 50°C for 8h; after the reaction, remove insoluble matter, concentrate the reaction solution, and purify and isolate the product by toluene column chromatography , vacuum dried to constant weight to ...

Embodiment 2

[0036] (1) It is 70% ethylamine aqueous solution (9.54g, wherein containing ethylamine 6.75g, 0.15mol) and acidic catalyst (85%H 3 PO 4 , 0.25g), warming up to 50 ° C, dropwise added a mass fraction of 70% trimethylolpropane-three (3- aziridinyl propionate) aqueous solution (35.42g, which contains trimethylolpropane-three (3-Aziridinyl propionate) 21.25 g, 0.05 mol), the dropping time is 40 min. After the dropwise addition, the temperature was raised to 70° C. for 5 h.

[0037] (2) The above reaction solution was mixed with K 2 CO 3 Adjust to weakly alkaline (pH=9~10), add dropwise 3-chloro-2-hydroxypropyl-trimethylammonium chloride aqueous solution (70.50g, containing 3-chloro-2- Hydroxypropyl-trimethylammonium chloride 56.40g, 0.30mol), dropwise time is 60min, react at 70°C for 4h; after the reaction, remove the insoluble matter, concentrate the reaction solution, and use toluene column chromatography to purify and isolate the product , vacuum dried to constant weight t...

Embodiment 3

[0049] A preparation method of a cationic star-shaped flocculant with dense charges, comprising the steps of:

[0050] (1) Be that 80% octadecyl primary amine ethanol solution (50.44g, wherein contain octadecyl primary amine 40.35g, 0.15mol) and acidic catalyst (85%H 3 PO 4 , 0.25g), warming up to 50 ° C, dropwise added a mass fraction of 70% trimethylolpropane-three (3- aziridinyl propionate) aqueous solution (35.42g, which contains trimethylolpropane-three (3-Aziridinyl propionate) 21.25 g, 0.05 mol), the dropping time is 40 min. After the dropwise addition was completed, the temperature was raised to 80° C. for 6 h.

[0051] (2) The above reaction solution was mixed with K 2 CO 3 Adjust to weakly alkaline (pH=9~10), add dropwise 3-chloro-2-hydroxypropyl-trimethylammonium chloride aqueous solution (70.50g, containing 3-chloro-2- Hydroxypropyl-trimethylammonium chloride 56.40g, 0.30mol), dropwise time is 60min, react at 70°C for 4h; after the reaction, remove the insolub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oil removal rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com