Method for improving dispersion stability of silicon carbide powder in water system

A silicon carbide powder and dispersion stability technology, applied in the field of silicon carbide ceramics, can solve the problems of easy agglomeration and sedimentation, difficult slurry, etc., and achieve the effect of low cost, good dispersion and high stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] In the present embodiment, the preparation method of silicon carbide ceramic powder is as follows:

[0026] (1) Disperse silicon carbide powder in distilled water, the ratio of silicon carbide powder mass to distilled water mass is 1:1, then add sucrose ester surfactant solution, so that the mass of sucrose ester accounts for 25% of the mass of silicon carbide, at 750r / min under the condition of mixing and stirring for 5h to obtain silicon carbide slurry;

[0027] The sucrose ester in the surfactant solution is used as a dispersant, and ethanol and acetone are used as a solvent, which is prepared by dissolving the sucrose ester at a temperature of 60-80°C, and then adding ethanol and acetone;

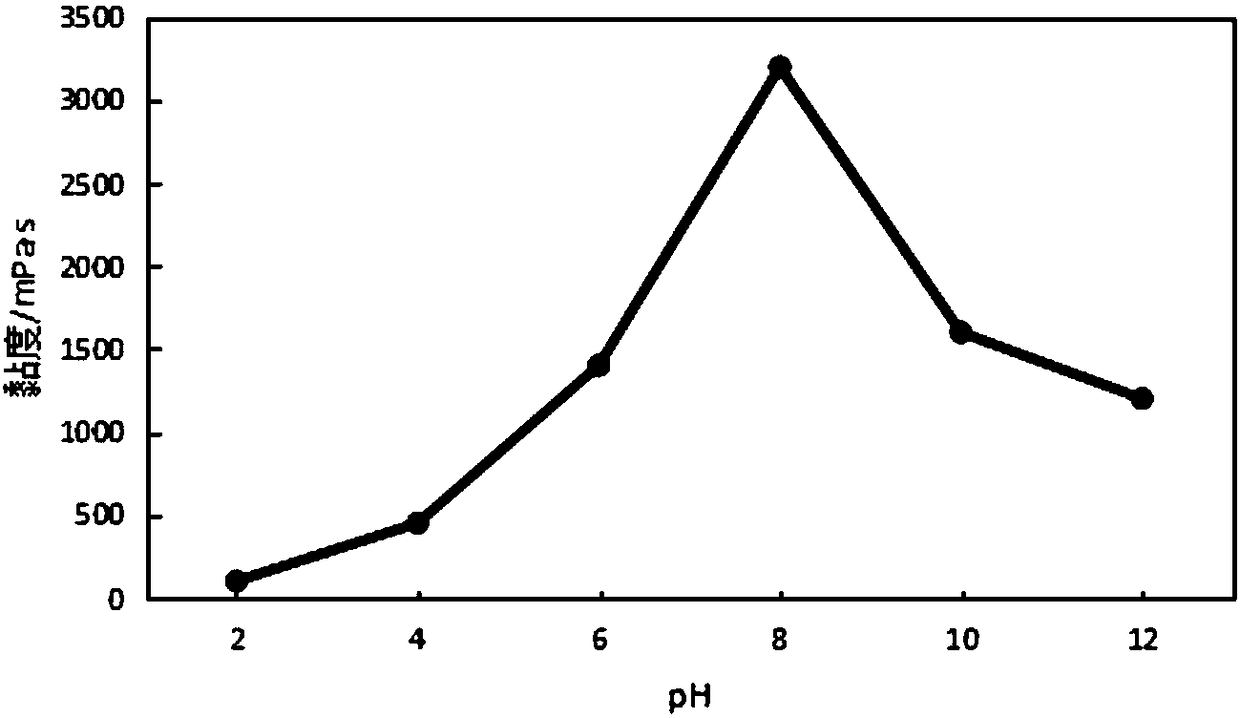

[0028] Then, adjust the pH value of the silicon carbide slurry with ammonia water and hydrochloric acid to obtain six groups of slurries with pHs of 2, 4, 6, 8, 10, and 12 respectively, and continue to stir for 1 hour under the condition of 300r / min. Adjust the pH value of the ...

Embodiment 2

[0039] In the present embodiment, the preparation method of silicon carbide ceramic powder is as follows:

[0040] (1) Disperse silicon carbide powder in distilled water, the ratio of silicon carbide powder mass to distilled water mass is 1:1, then add sucrose ester surfactant solution, so that the mass of sucrose ester accounts for 5% and 10% of the mass of silicon carbide respectively , 15%, 20%, 25%, 30%, mixed and stirred for 5 hours under the condition of 750r / min to obtain six groups of silicon carbide slurries;

[0041] The sucrose ester in the surfactant solution is used as a dispersant, and ethanol and acetone are used as a solvent, which is prepared by dissolving the sucrose ester at a temperature of 60-80°C, and then adding ethanol and acetone;

[0042] Then, adjust the pH value of the silicon carbide slurry with ammonia water and hydrochloric acid to obtain a pH of 10, continue stirring for 1 hour under the condition of 300r / min, and adjust the pH value of the sili...

Embodiment 3

[0046] (1) It is basically the same as step (1) in Example 1, except that the mass of sucrose ester accounts for 5% of the mass of silicon carbide, and the pH value of the silicon carbide slurry is adjusted to 10 with ammonia water and hydrochloric acid;

[0047] (2) is the same as step (2) in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com