Liquid fertilizer prepared taking biochar as raw material

A technology of liquid fertilizer and biochar, which is applied in the field of liquid fertilizer, can solve the problems of unfavorable transportation, large-scale promotion, inability to apply liquid fertilizer, and low effective nutrients, so as to prolong the time of fertilizer effect, prevent pollution of plants, and ensure the effect of fertilizer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

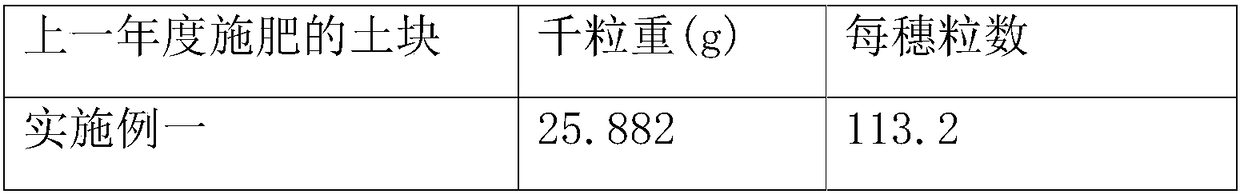

Embodiment 1

[0037] A liquid fertilizer prepared from biochar as a raw material, prepared by the following steps:

[0038] S1. Evenly mix bacteria packs, algae, mung bean leaves, liquid human and animal manure, EM bacteria agent, bentonite or river pond sludge according to the following weight ratio: 1:1.5:1.5:5:0.15:2, mix and load Anaerobic fermentation is carried out in the fermentation tank, the fermentation temperature is controlled at 30°C, and the fermentation time is 20 days; after the fermentation is completed, the liquid is filtered to obtain the first fermentation liquid; the algae or water hyacinth, mung bean leaves or mung bean stems are beaten into paste by a beater or pulp for reuse.

[0039] S2. Crush the green wheat stalks and corn stalks to particles with a particle size of 1.5 cm, then mix the wheat stalks, corn stalks, and the first fermentation liquid evenly in a ratio of 2:1.5:12 by weight, and put them into fermentation again. Anaerobic fermentation is carried out i...

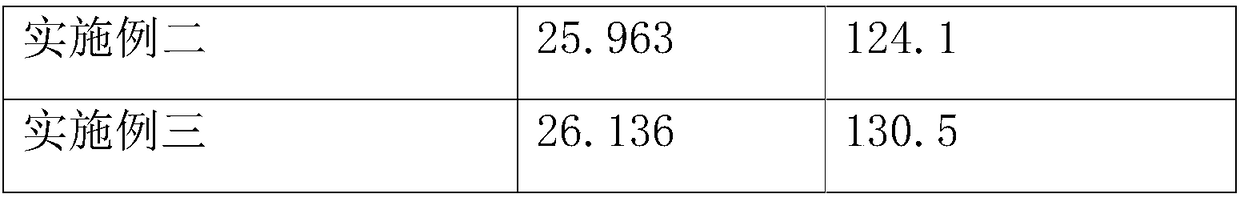

Embodiment 2

[0048] A liquid fertilizer prepared from biochar as a raw material, prepared by the following steps:

[0049] S1. Evenly mix the bacterial bag, water hyacinth, mung bean stalk, liquid human and animal manure, EM bacterial agent, bentonite or river pond sludge according to the following weight ratio: 1:2:2:6:0.15:2.5, after mixing After the pulper is beaten into slurry, it is put into the fermentation tank for anaerobic fermentation. The fermentation temperature is controlled at 20-40°C, and the fermentation time is 30 days; after the fermentation is completed, the liquid is filtered to obtain the first fermentation liquid;

[0050] S2. Crush the green wheat stalks and corn stalks into particles with a particle size of 1-2 cm, then mix the wheat stalks, corn stalks, and the first fermentation liquid evenly in a ratio of 3:1:15 by weight, and put them in again Anaerobic fermentation is carried out in the fermentation tank, the fermentation temperature is controlled at 20-30°C, a...

Embodiment 3

[0059] A liquid fertilizer prepared from biochar as a raw material, prepared by the following steps:

[0060] S1. Evenly mix the bacterial bag, water hyacinth, mung bean stalk, liquid human and animal manure, EM bacterial agent, bentonite or river pond sludge according to the following weight ratio: 1:2:2:6:0.15:3, mix and load Enter the fermentation tank for anaerobic fermentation, the fermentation temperature is controlled at 20-40°C, and the fermentation time is 40 days; after the fermentation is completed, the liquid is filtered to obtain the first fermentation liquid;

[0061] S2. Crush the green wheat stalks and corn stalks into particles with a particle size of 1-2 cm, then mix the wheat stalks, corn stalks, and the first fermentation liquid evenly in a ratio of 2.5:1:10 by weight, and put them in again Anaerobic fermentation is carried out in the fermentation tank, the fermentation temperature is controlled at 20-30°C, and the fermentation time is 10-15 days; after the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com