Novel organic mineral liquid humic acid fertilizer

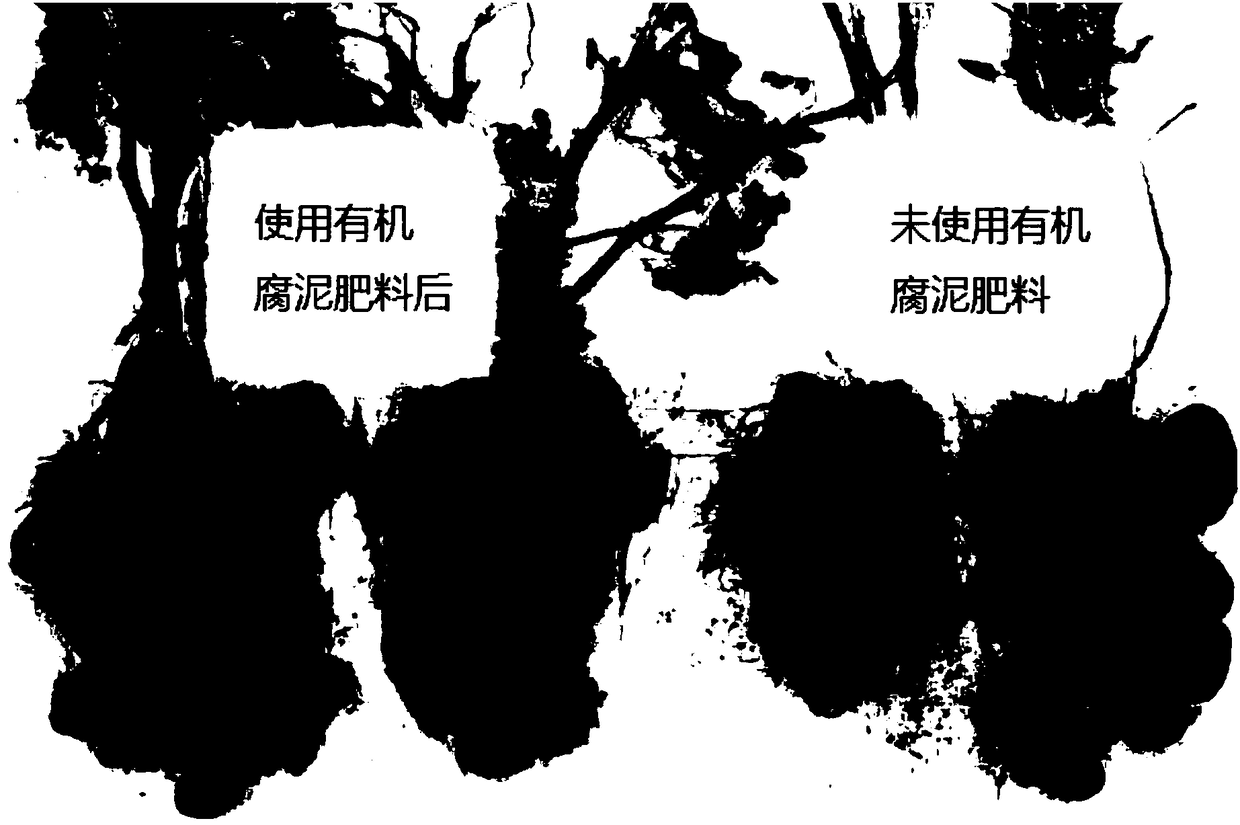

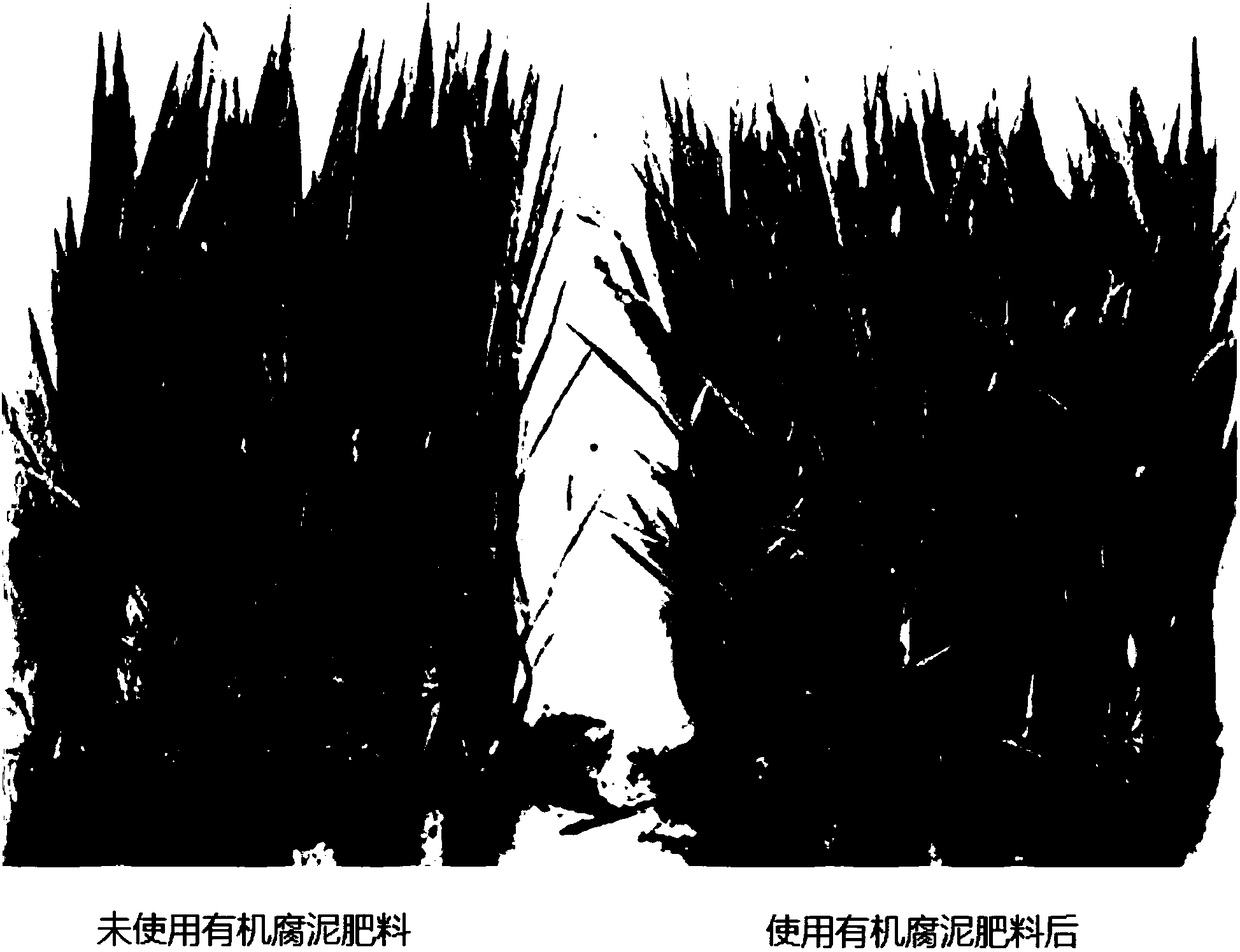

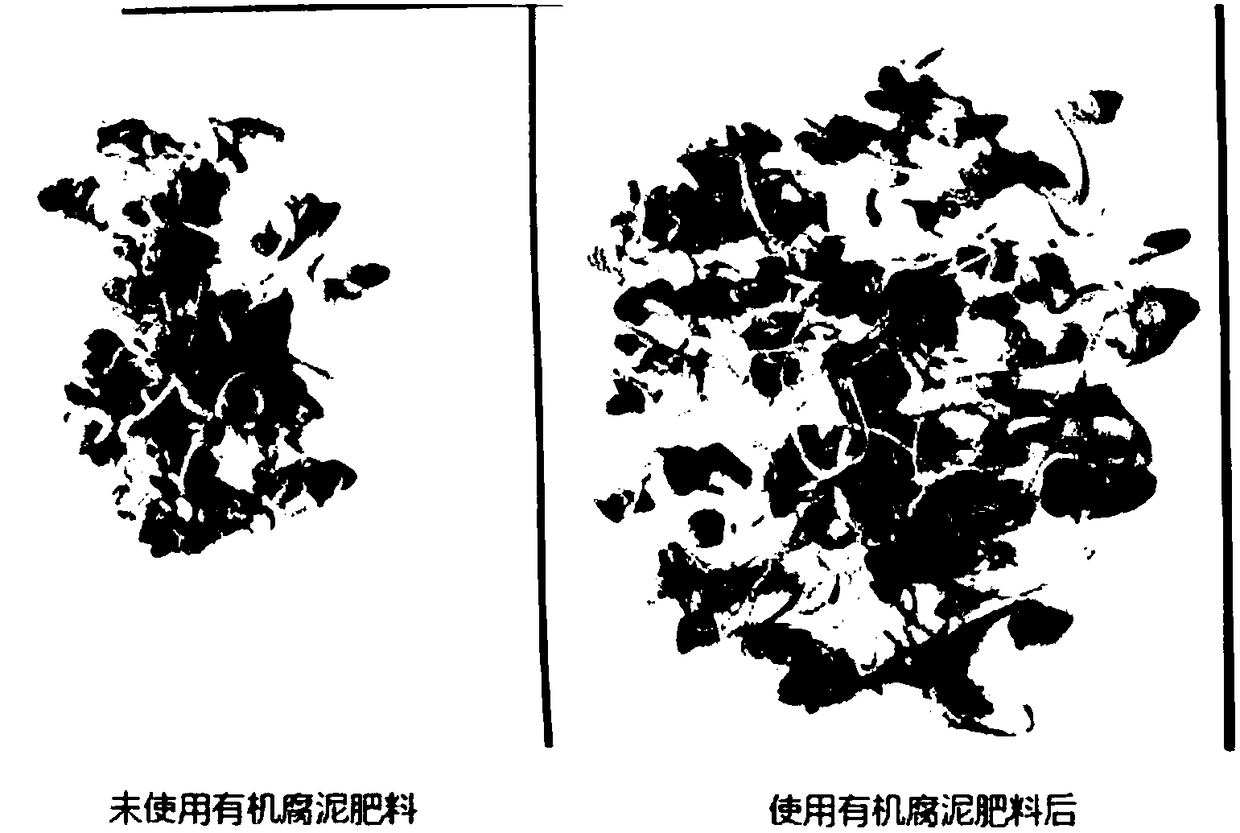

An organic mineral and humic acid technology, applied in the field of agricultural production, can solve the problems of complex composition and reduce the energy efficiency of humic acid, and achieve the effects of strengthening resistance, increasing seed germination and germination energy, and increasing yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The preparation of novel organic mineral liquid humic acid fertilizer is prepared from the following components by weight: 18 kilograms of natural sapropel (water content is 90-93%), 4.32 kilograms of potassium pyrophosphate, and 10 liters of water.

[0024] The above raw materials are all commercially available products, and there is no restriction on the manufacturer.

[0025] Preparation method: First, add 18 kilograms of natural sapropel mud (with a water content of 90-93%) in a material tank, and add 10 liters of water to heat to 80 degrees Celsius. Pour the prepared 4.32 kg of potassium pyrophosphate hot solution into a sapropelic material tank, and stir it homogeneously for 3 hours; then add 100 liters of cold water to the material tank, and continue stirring for 2 hours; finally place it under room temperature for 12 hours Hours, the sieve (200 micron pores) can be used after filtering; finally, the humic acid content can be tested by photometry at a wavelength ...

Embodiment 2

[0032] Referring to the proportioning and production method of Example 1, but due to different raw material sampling periods. According to the content of humic acid, the photometric method is used to test at a wavelength of 440±10nm: the content of fulvic acid is tested by the method of measuring the content of humus in the soil-titrimetric method: the nitrogen content is tested by Kjeldahl titration method: the phosphorus content is measured by photometry Determination: Potassium content is measured by flame photometry: it can be seen that the main content in the final product is, g / L:

[0033] Humic Acid-4.0

[0034] Fulvic acid-1.8

[0035] Phosphorus (by Р 2 О 5 Calculation) - 10.0

[0036] Potassium (by К 2 О calculation)-16.0

[0037] Nitrogen - 0.32

Embodiment 3

[0039] Referring to the proportioning and production method of Example 1, but due to different raw material sampling periods. According to the content of humic acid, the photometric method is used to test at a wavelength of 440±10nm: the content of fulvic acid is tested by the method of measuring the content of humus in the soil-titrimetric method: the nitrogen content is tested by Kjeldahl titration method: the phosphorus content is measured by photometry Determination: Potassium content is measured by flame photometry: it can be seen that the main content in the final product is, g / L:

[0040] Humic Acid-2.0

[0041] Fulvic acid-0.92

[0042] Phosphorus (by Р 2 О 5 Calculation) - 8.0

[0043] Potassium (by К 2 О calculation) - 14.4

[0044] Nitrogen - 0.20

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com