Anti-ponding ecological rod surface for landscaping and preparation method

A technology for landscaping and preventing water accumulation, applied in the field of landscaping, can solve the problems of insufficient compressive strength, low ability to adjust the temperature and humidity of the urban surface, and silted rivers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

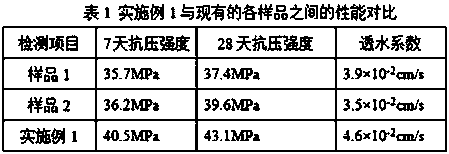

Embodiment 1

[0032] A kind of anti-accumulation ecological pavement for landscaping, described ecological pavement comprises the substrate layer that is positioned at the upper layer, the permeable layer that is positioned at the lower layer and the mortar layer that described substrate layer, described permeable layer are bonded together, by weight parts , the base layer includes 45 parts of composite binder, 120 parts of solid waste coarse aggregate, 100 parts of solid waste fine aggregate, 10 parts of admixture, and 15 parts of water; in parts by weight, the permeable The layer includes 40 parts of binder, 120 parts of solid waste coarse aggregate, 80 parts of fiber, 5 parts of admixture, and 8 parts of water; the binder is mixed with cement and fly ash in a mass ratio of 2:1 The solid waste coarse aggregate includes steel slag, ferrochrome slag, and coal gangue crushed to porous particles with a particle size of 5-20mm, and the solid waste fine aggregate includes steel slag, ferrochrome...

Embodiment 2

[0056] A kind of anti-accumulation ecological pavement for landscaping, described ecological pavement comprises the substrate layer that is positioned at the upper layer, the permeable layer that is positioned at the lower layer and the mortar layer that described substrate layer, described permeable layer are bonded together, by weight parts , the base layer includes 50 parts of composite binder, 150 parts of solid waste coarse aggregate, 110 parts of solid waste fine aggregate, 15 parts of admixture, and 20 parts of water; in parts by weight, the permeable Layer comprises 42 parts of binder, 150 parts of solid waste coarse aggregate, 100 parts of fiber, 7 parts of admixture, 9 parts of water; Described composite binder is made of cement, humic acid, biochar by 4: The mass ratio of 1:0.5 is mixed. The binder is mixed with cement and fly ash in a mass ratio of 3:1. A certain amount of humic acid is added to the binder of the base layer. Humic acid and biochar, humic acid is th...

Embodiment 3

[0080] A kind of anti-accumulation ecological pavement for landscaping, described ecological pavement comprises the substrate layer that is positioned at the upper layer, the permeable layer that is positioned at the lower layer and the mortar layer that described substrate layer, described permeable layer are bonded together, by weight parts , the base layer includes 55 parts of composite binder, 180 parts of solid waste coarse aggregate, 120 parts of solid waste fine aggregate, 20 parts of admixture, and 25 parts of water; in parts by weight, the permeable The layer includes 45 parts of binder, 180 parts of solid waste coarse aggregate, 120 parts of fiber, 8 parts of admixture, and 10 parts of water; the binder is mixed with cement and fly ash in a mass ratio of 4:1 The solid waste coarse aggregate includes steel slag, ferrochrome slag, and coal gangue crushed to porous particles with a particle size of 5-20mm, and the solid waste fine aggregate includes steel slag, ferrochro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com