Heat-preservation fireproof composite plate

A composite board, thermal insulation technology, applied in thermal insulation, fire protection, building components and other directions, to achieve the effect of reasonable design, wide application range and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

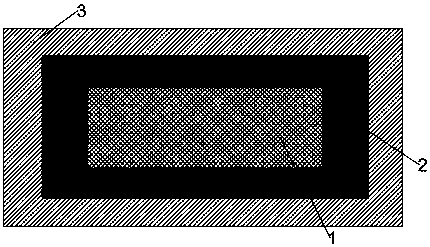

Image

Examples

Embodiment 1

[0021] A thermal insulation and fireproof composite board, including a thermal insulation substrate and a fireproof mortar layer, the thermal insulation substrate includes a core material and an outer layer board, and the core material is wrapped inside the outer layer board, the outer layer board is made of polystyrene granular material, and the fireproof mortar layer is coated on the Insulation substrate surface. A gas-barrier film is also arranged between the core material and the outer layer board, and the gas-barrier film is wrapped outside the core material and sealed with the core material by vacuuming. The fireproof mortar layer includes the following raw materials in parts by weight: 5 parts of fly ash, 6 parts of acrylic acid emulsion, 2 parts of alkaline silica sol, 18 parts of ultrafine silica powder, 2.6 parts of chopped fiber, 6 parts of sand, vitrified micro 0.8 parts of beads and 0.6 parts of sodium citrate.

[0022] The preparation method of the thermal insul...

Embodiment 2

[0028] A thermal insulation and fireproof composite board, including a thermal insulation substrate and a fireproof mortar layer, the thermal insulation substrate includes a core material and an outer layer board, and the core material is wrapped inside the outer layer board, the outer layer board is made of polystyrene granular material, and the fireproof mortar layer is coated on the Insulation substrate surface. The core material is made of polyurethane material or silicate material. The exterior of the fireproof mortar layer is covered with a waterproof layer, and the waterproof layer is made of flexible water-resistant putty. The fireproof mortar layer includes the following raw materials in parts by weight: 7.5 parts of fly ash, 10 parts of acrylic acid emulsion, 3.2 parts of alkaline silica sol, 21 parts of ultrafine silica powder, 4.5 parts of chopped fiber, 9 parts of sand, vitrified micro Beads 1.2 parts and Sodium Citrate 1.0 parts.

[0029] The preparation method...

Embodiment 3

[0035] A thermal insulation and fireproof composite board, including a thermal insulation substrate and a fireproof mortar layer, the thermal insulation substrate includes a core material and an outer layer board, and the core material is wrapped inside the outer layer board, the outer layer board is made of polystyrene granular material, and the fireproof mortar layer is coated on the Insulation substrate surface. A gas-barrier film is also arranged between the core material and the outer layer board, and the gas-barrier film is wrapped outside the core material and sealed with the core material by vacuuming. The core material is made of polyurethane material or silicate material. The exterior of the fireproof mortar layer is covered with a waterproof layer, and the waterproof layer is made of flexible water-resistant putty. The fireproof mortar layer includes the following raw materials in parts by weight: 9 parts of fly ash, 12 parts of acrylic acid emulsion, 4 parts of al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com