Responsive photonic crystal elastomer membrane material, preparation and application thereof

A photonic crystal and responsive technology, applied in optics, optical components, instruments, etc., can solve the problems of inability to achieve self-repair and reuse, stretching is difficult to use again, and complicated preparation process, so as to achieve the convenience of large-scale preparation and low cost. Convenience and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] The invention provides a method for preparing the above-mentioned responsive photonic crystal elastomer film material, comprising the following steps:

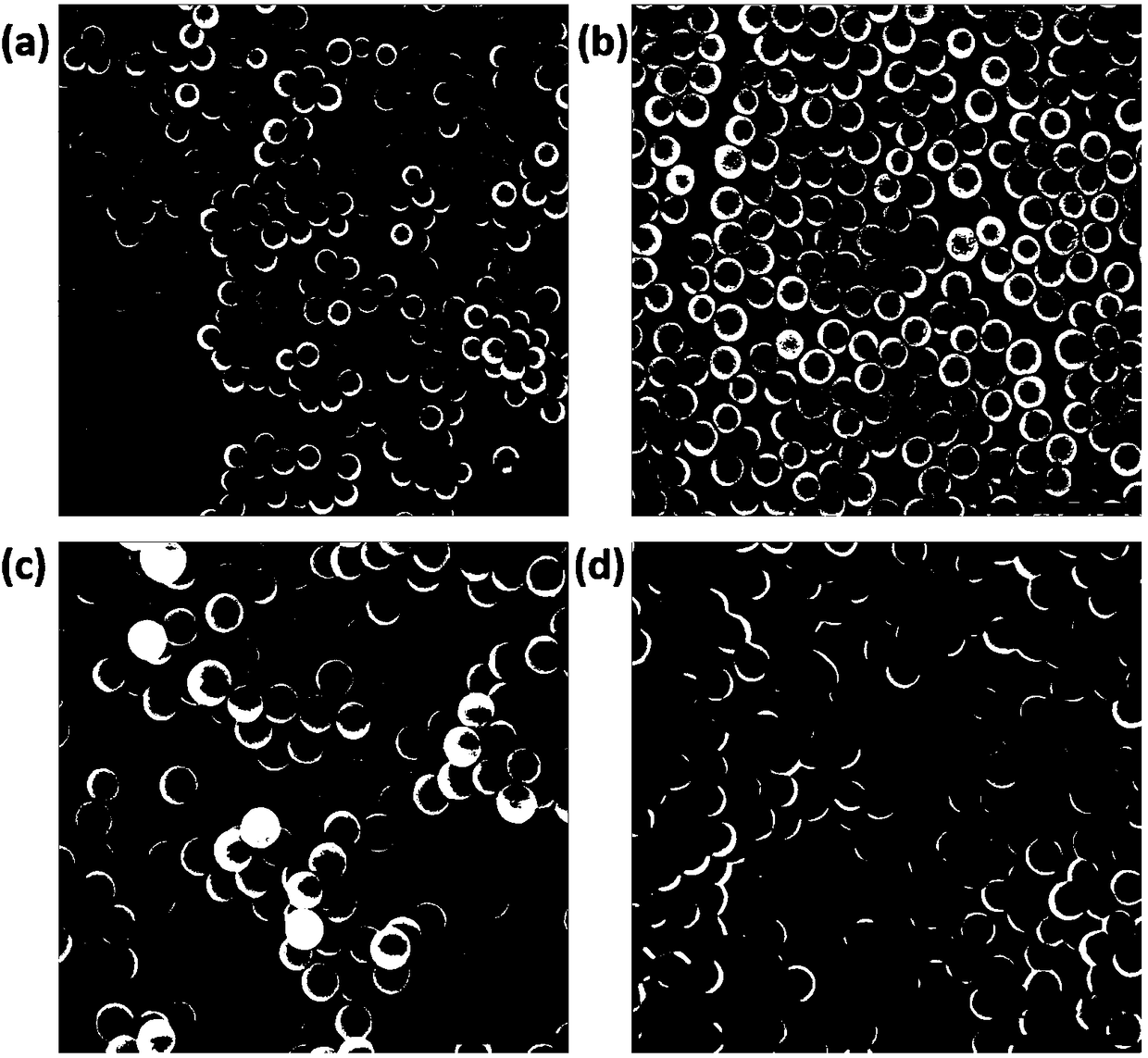

[0051] (1) Preparation of modified nanoparticles: under the action of a modifier, the nanoparticles are cross-linked and modified by the sol-gel method. The specific method is: then the modified nanoparticles are dispersed in an organic solvent, wherein the modified The mass concentration of non-toxic nanoparticles is 1% to 50%; the nanoparticles are solid spheres or core-shell spherical particles with a size in the range of 100-500nm that will not dissolve in organic solvents; the nanoparticles are preferably SiO 2 Nanoparticles, polystyrene nanoparticles or polymethacrylic acid nanoparticles; the modifier is an oil-soluble polymer with a molecular weight of less than 40,000, preferably 600 to 30,000 g / mol, and the modified nanoparticles preferably have a molecular weight greater than 40 % degree of crosslinking.

[...

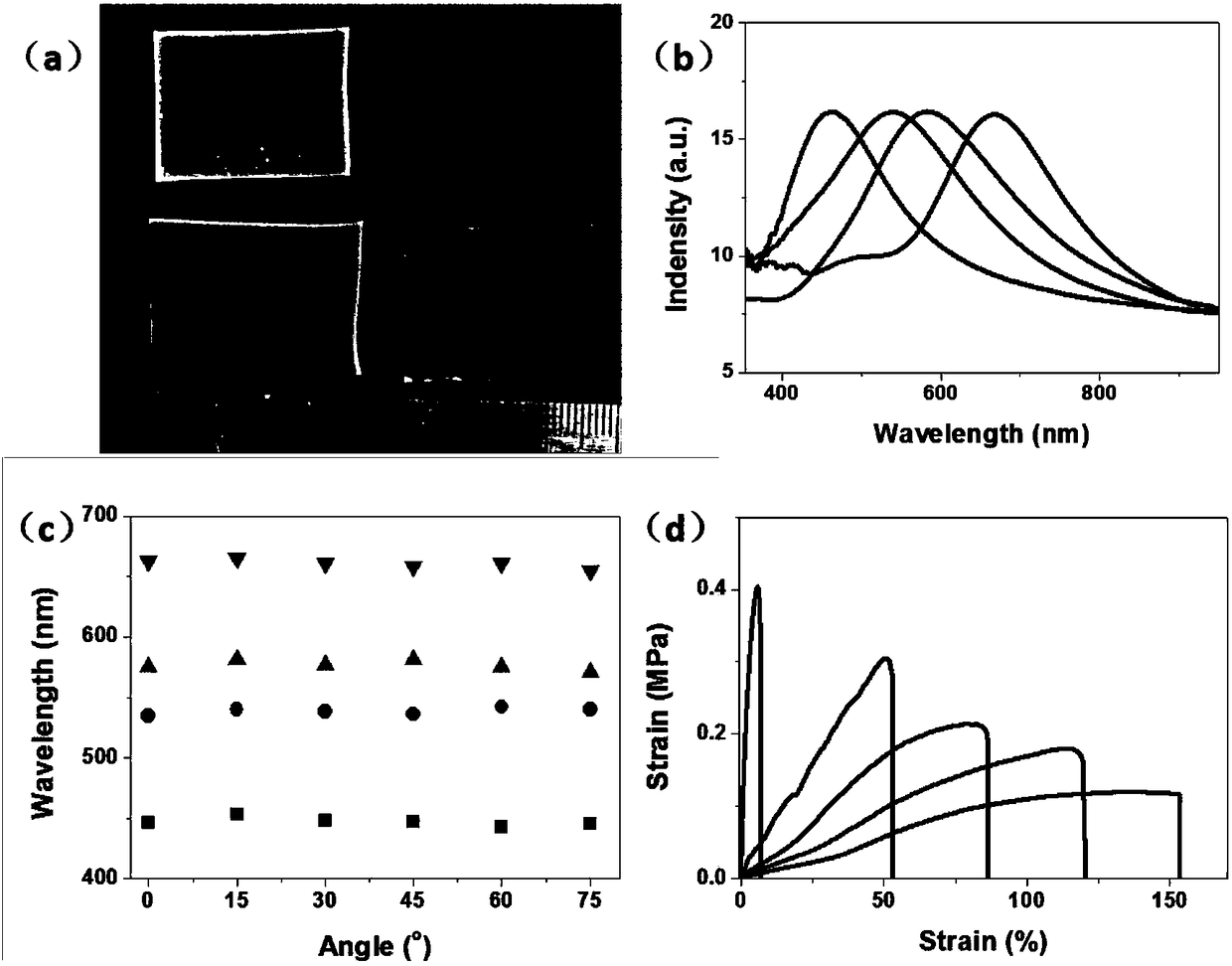

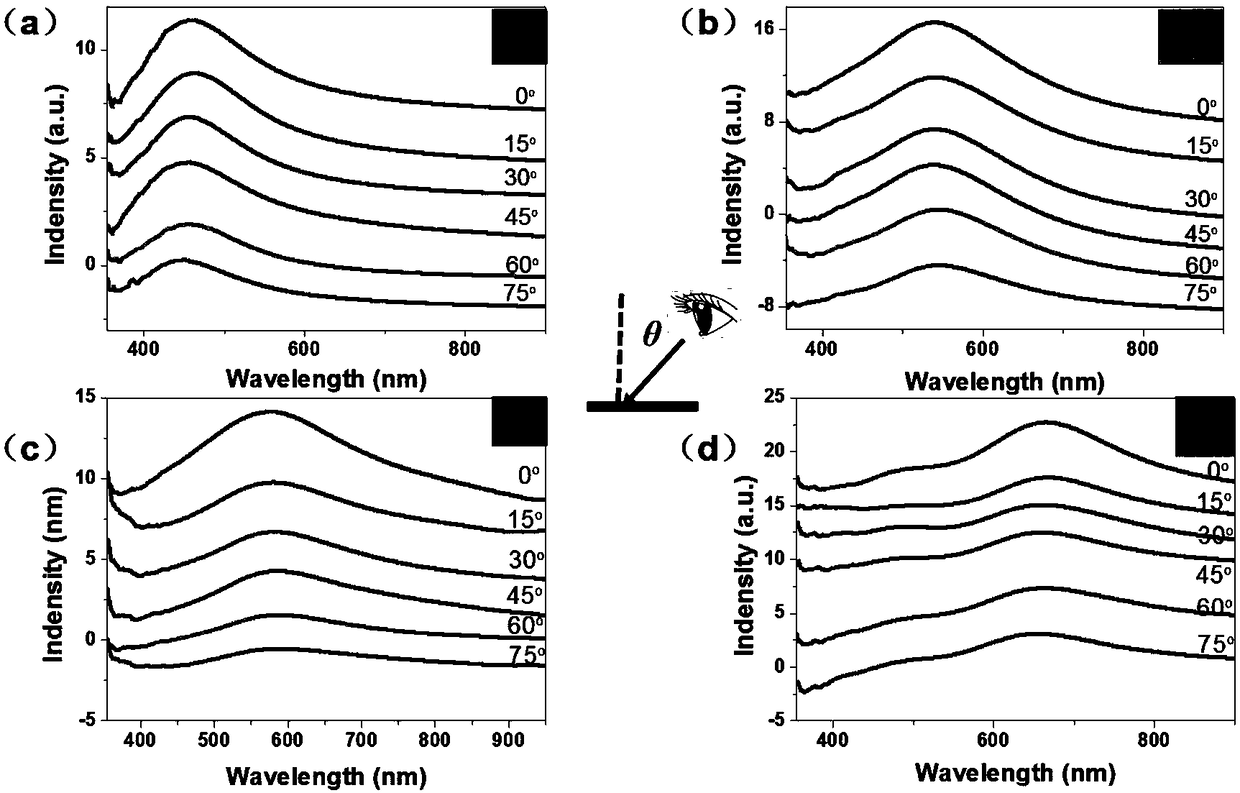

Embodiment 1

[0059] (1) Synthesis and modification of silica nanoparticles: Dissolve 8mL of ammonia water and 4mL of water in 100mL of ethanol, and after stirring for ten minutes, add 3mL of TEOS dropwise, stir rapidly for 15min after the addition, and then reduce the stirring speed. React at 30°C for 5-6h. After the reaction is completed, centrifuge at 8000rpm, wash with hydrochloric acid ethanol solution, water and ethanol in sequence, and vacuum-dry the nanoparticles obtained by centrifugation at 50°C to obtain a white solid. Then ultrasonically disperse 1 g of silica nanoparticles in 85 mL of ethanol, add dropwise 30 mL of ethanol solution of ammonia (88 mL of ammonia / 320 mL of ethanol) under stirring, stir at 40 for 1 h, and then add triethoxy Slowly add the ethanol solution of the group-terminated PDMS into the above solution, and react for 24 hours after the addition is completed. The product is centrifuged at a speed of 7000rpm to obtain silica with a diameter of 170nm, washed with ...

Embodiment 2

[0063] (1) Synthesis and modification of silica nanoparticles: Dissolve 8mL of ammonia water and 4mL of water in 100mL of ethanol, and after stirring for ten minutes, add 3mL of TEOS dropwise, stir rapidly for 15min after the addition, and then reduce the stirring speed. React at 30°C for 5-6h. After the reaction is completed, centrifuge at 8000rpm, wash with hydrochloric acid ethanol solution, water and ethanol in sequence, and the nanoparticles obtained by centrifugation are vacuum-dried at 50°C to obtain a white solid. Then ultrasonically disperse 1 g of silica nanoparticles in 85 mL of ethanol, add dropwise 30 mL of ethanol solution of ammonia water (88 mL of ammonia water / 320 mL of ethanol) under stirring, stir at 40°C for 1 h, and then add triethyl ether with a molecular weight of 600-900 g / mol The ethanol solution of oxygen-terminated PDMS was slowly added dropwise to the above solution. After the addition was completed and reacted for 24 hours, the product was centrifug...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com