Fabrication method of curved microlens array with focal length varying with spatial distribution

A technology of microlens array and spatial distribution, which is applied in the production field of curved surface microlens array, can solve the problems of high production cost, expensive rotatable and movable laser emission source, unsuitable for mass production, etc., and achieve low cost and optimal control , the effect of simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

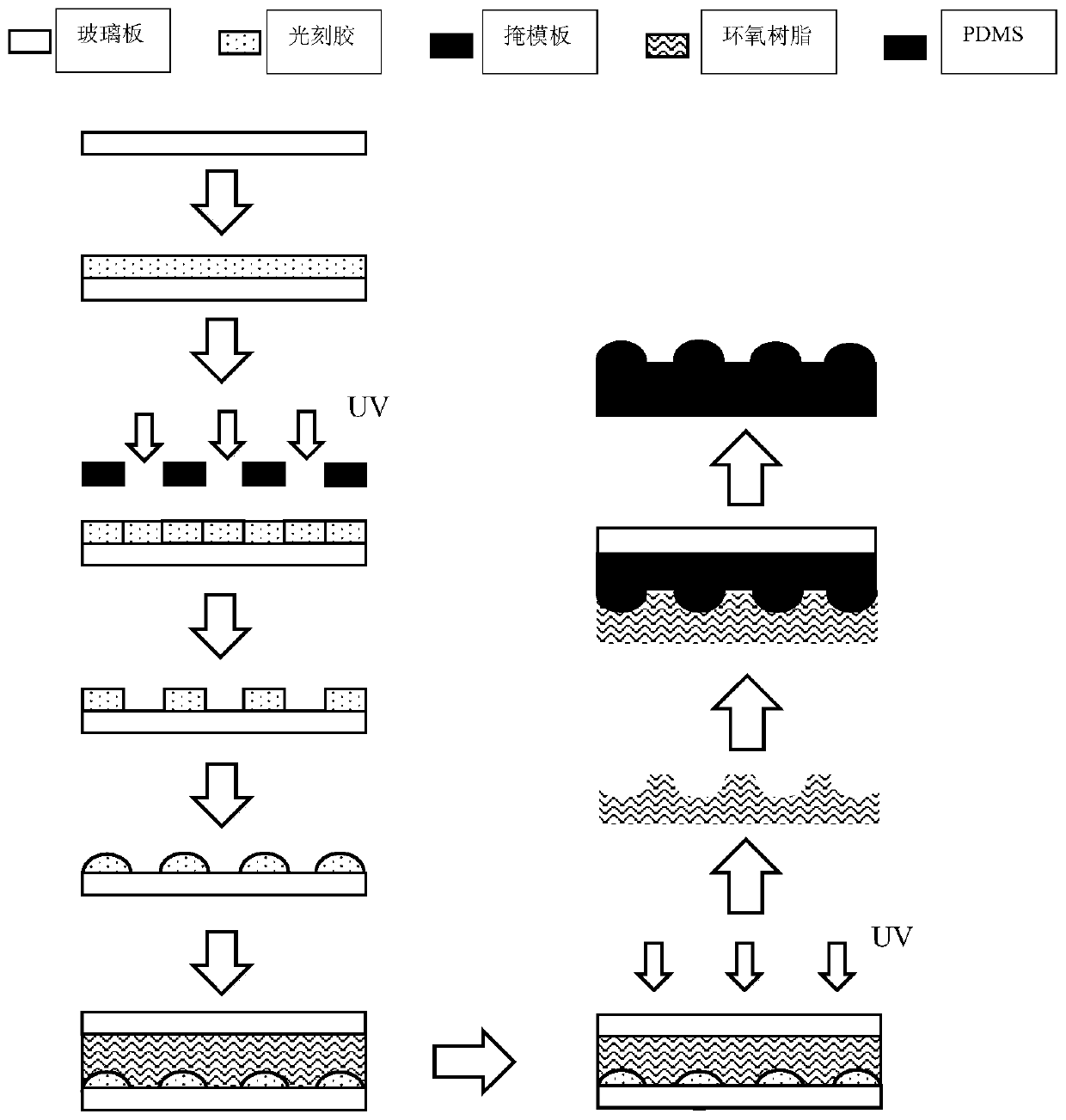

[0025] The invention discloses a manufacturing method of a curved surface microlens array whose focal length varies with spatial distribution, such as figure 1 As shown, the following process steps are included:

[0026] 1. Take a glass sheet with a flat surface as the substrate, wash the glass sheet with water and acetone, place it in an oven, and bake it at 130°C for 10 minutes to remove water vapor and residual acetone. After baking, perform oxygen plasma treatment. Increase the surface energy of the glass sheet.

[0027] 2. Spin-coat the positive photoresist (AZ4620) on the cleaned substrate. After pre-baking, a uniform adhesive layer is formed on one side of the substrate. Place the adhesive layer side of the substrate under the pre-made circular hole mask for UV exposure. , the substrate is spaced but parallel to the circular hole mask, and the ultraviolet light is irradiated vertically on the circular hole mask. The circular hole mask includes a light-transmitting area...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com