Overhead insulated power cable

A power cable and overhead insulation technology, which is applied in the direction of insulated cables, power cables, power cables for overhead applications, etc., can solve the problems of high operation failure rate, large line loss, poor wind and snow resistance, etc., and achieve large transmission capacity , long service life, and the effect of improving electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

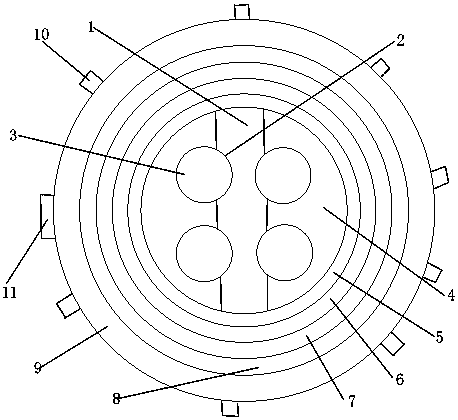

[0016] Such as figure 1 As shown, an overhead insulated power cable includes a conductor support frame 1, and a plurality of arc-shaped grooves 2 are opened on the conductor support frame, and an aluminum alloy conductor 3 is correspondingly provided in each arc-shaped groove, which is combined into a cable Core; a filling layer 4 is provided in the gap of the cable core, and a heat-resistant 105°C weather-resistant chemical cross-linked polyethylene insulating layer 5 is extruded outside the cable core, and a heat-resistant 105°C weather-resistant chemical cross-linked polyethylene insulating layer is placed on the outside of the cable core. The outer braided steel wire shielding layer 6 is wrapped with an impact-resistant layer 7 outside the steel wire shielding layer, and an oxygen barrier layer 8 is arranged outside the impact-resistant layer, and an outer sheath 9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com