Aluminum-air battery, battery pack and power generator set

A technology for aluminum-air battery and generator set, applied in the field of battery pack, generator set, and aluminum-air battery, can solve the problems of complex processing technology, leakage of electrolyte, increase in size of the stack, etc., and achieve simple operation and processing technology, prevent The positive contact is short-circuited and the effect of counteracting the relative expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

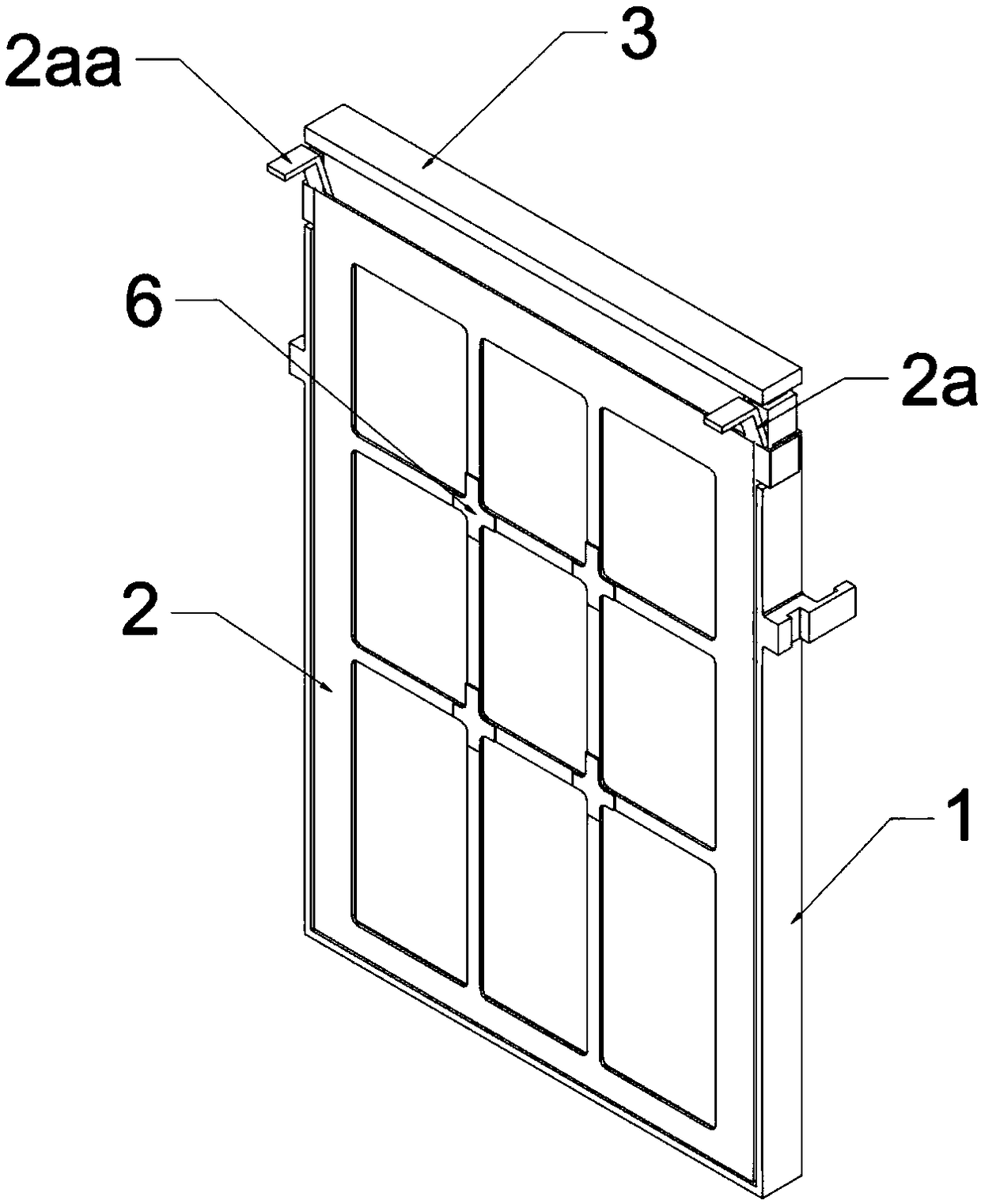

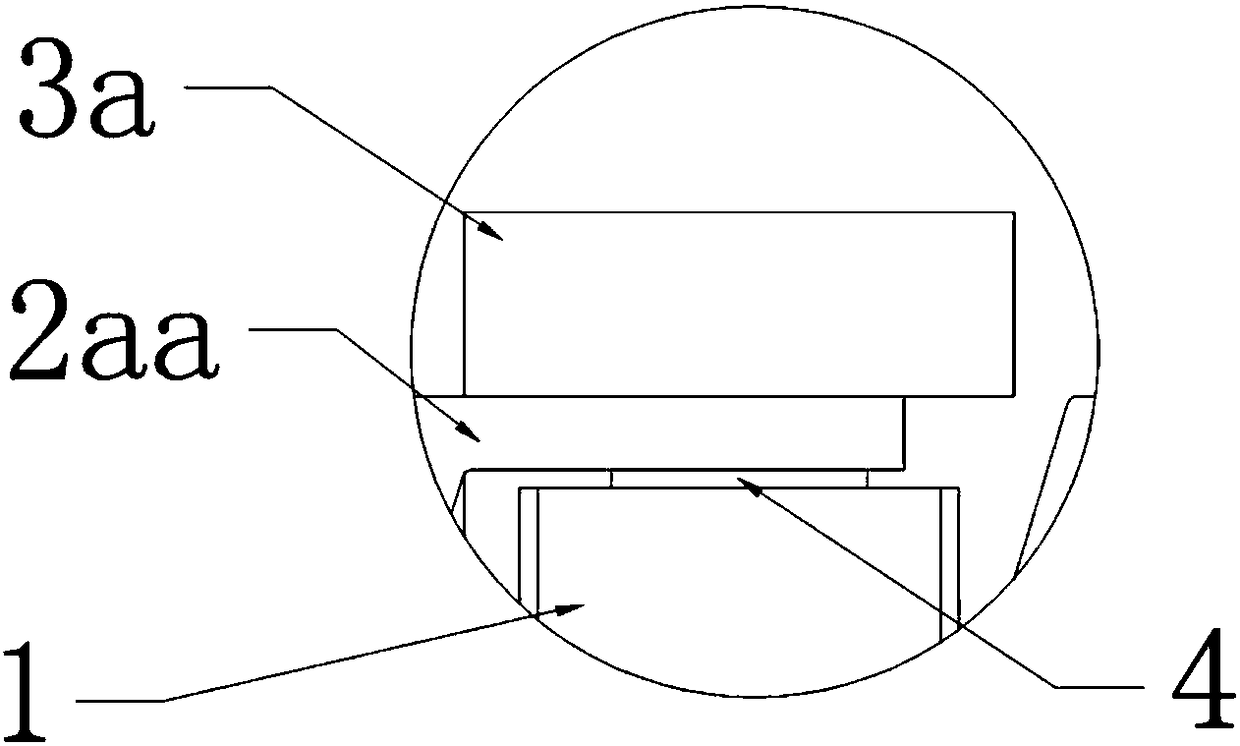

[0031] like Figure 1 to Figure 4 The shown aluminum-air battery includes a battery body, the battery body includes a battery liquid cavity 1, an aluminum plate 5 is inserted in the battery liquid cavity 1, a negative plate 3 is arranged on the aluminum plate 5, and the negative plate 3 A mounting groove 3b is respectively provided on the front and rear sides of the body, and the mounting groove 3b is provided throughout the body along the left and right directions. The battery liquid cavity 1 is provided with a positive plate 2, the positive plate 2 covers the front and rear surfaces of the battery liquid cavity 1, and a plurality of bosses 6 made of insulating material are arranged on the outer surface of each positive plate 2, and the convex Platform 6 is " ten " font. Each positive plate 2 is connected with a conductive lead-out bar 2a. As a preferred structural form, there are two lead-out bars 2a, which are located at the left and right ends of the positive plate 2 resp...

Embodiment 2

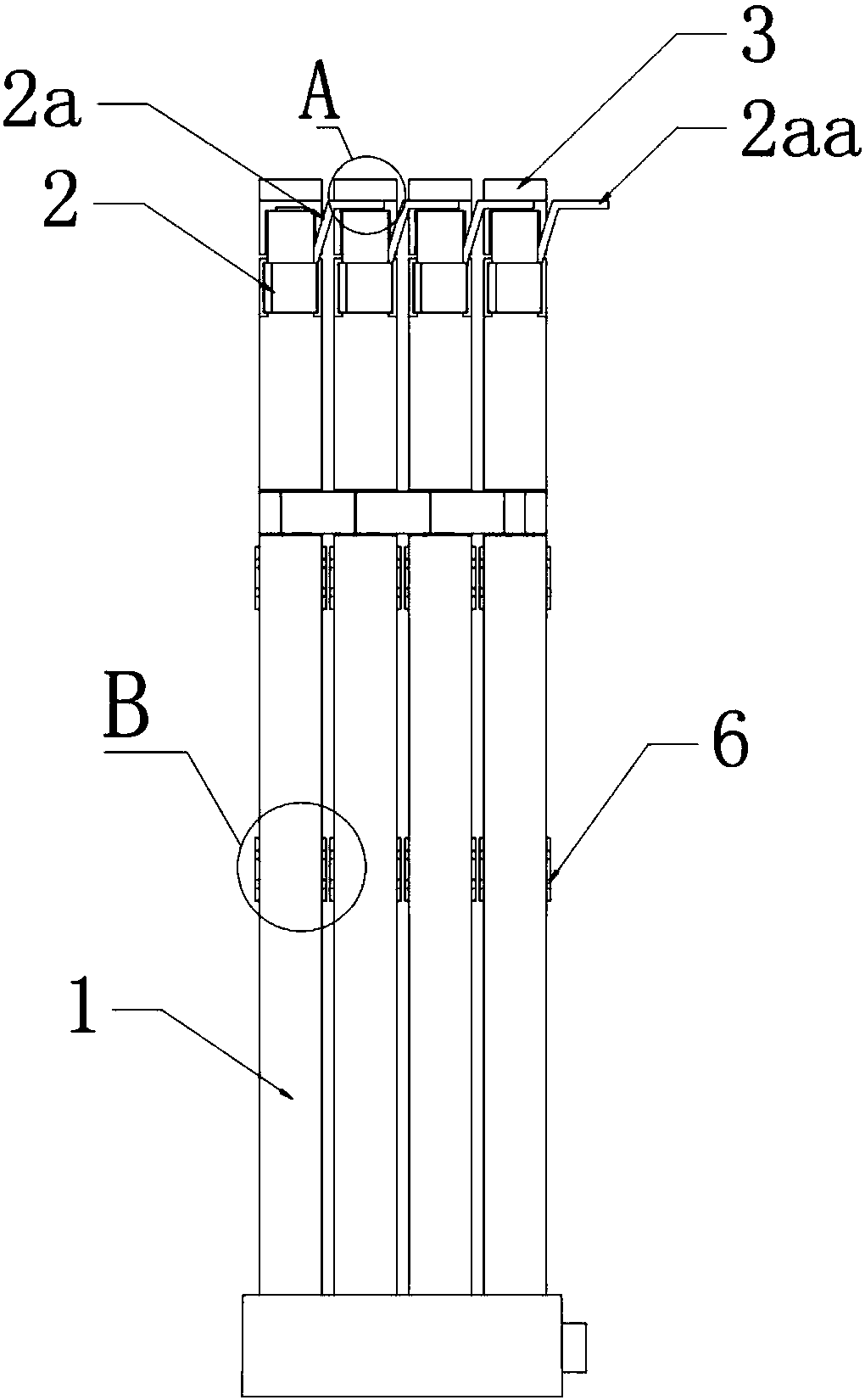

[0035] like Figure 1 to Figure 7 As shown, in this embodiment, the single cells in Embodiment 1 are used to form a battery pack. A plurality of battery bodies are arranged side by side in sequence and connected to form the main body of the battery pack. The lead-out bar 2a on each battery body is in contact with the negative electrode contact segment 3a on the next adjacent battery body. above, and the elastic member 4 elastically acts on the lead-out bar 2a, the lower ends of all battery liquid cavities 1 are connected to the same liquid tank 7, and all battery liquid cavities 1 are connected to the liquid tank 7, and all negative plates 3 It is fixed on the same insulating shell plate 8.

[0036] In this embodiment, in the specific implementation process, the battery cells in the first embodiment are utilized and combined in series to form a battery pack. Generally, the voltage of a single battery is 1V. According to the required target voltage, 12, 24 and 36 batteries ar...

Embodiment 3

[0038] like Figure 8 and Figure 9 As shown, in this embodiment, the battery pack in Embodiment 2 is used to form a generator set. A plurality of battery pack main bodies are connected in parallel or in series to form a generator set main body 10, all liquid tanks 7 are connected to each other, and a water pump 9 is provided to connect to the liquid tank 7, a cooling system 11 is provided next to the generator set main body 10, and the generator set The main body 10 is electrically connected to the organic unit control system and the inverter system.

[0039] In the specific implementation process of this embodiment, the battery packs formed by the method in the second embodiment are connected in series or in parallel to form an integral power supply, and the liquid tanks 7 of each battery pack are connected to uniformly feed and discharge liquid. In the liquid tank 7, a chlorine trioxide cleaning system is also provided. Actually, for the convenience of setting the chlorin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com