A kind of manufacturing method of multi-layer Teflon circuit board

A production method and circuit board technology, applied in the field of circuit board manufacturing, can solve the problems of warping, low melting temperature, and hollow glass fiber, improve quality and yield, optimize the entire process, and solve the problem of explosion and delamination. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0033] The invention provides a kind of manufacture method of multi-layer Teflon circuit board, comprises the following steps:

[0034] S1. Cut the Teflon substrate according to the required size to obtain the cutting board, bake the cutting board, the baking temperature is 150°C, and the baking time is 4 hours;

[0035] S2, roughen the surface of the cutting board, the roughening method is a roughening method other than mechanical grinding;

[0036] S3, making the inner layer circuit on the cutting board to obtain the inner layer board;

[0037] S4. Browning the copper surface on the inner layer board to obtain a browning board, wherein the browning rate is 3.0m / min; baking the browning board, the baking temperature is 150°C, and the baking time is 120min;

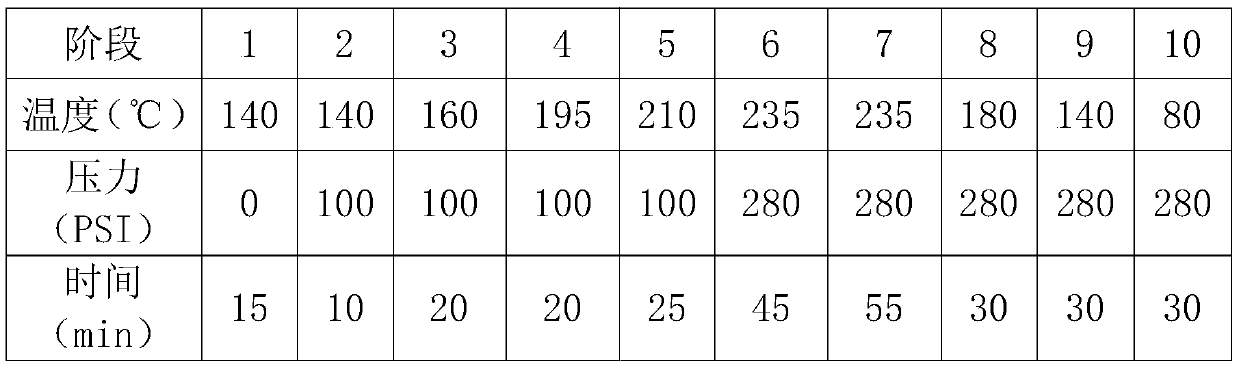

[0038] S5. Stack and press each board to make a multi-layer board; multi-stage pressing includes ten stages, and the specific method is as follows: the first stage pressing temperature is 140°C, pressing pressure is 0psi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com