Skeletal muscular myotubular dynamics measuring chip and preparation method thereof

A technology for skeletal muscle and myotubes, which is applied in the field of chips and preparation for intuitive and accurate observation and collection of skeletal muscle myotube contractility mechanical information, can solve the problems of low repeatability, deviation of statistical results, and high equipment requirements, so as to eliminate the influence of cells , easy to calculate the displacement, high repeatability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

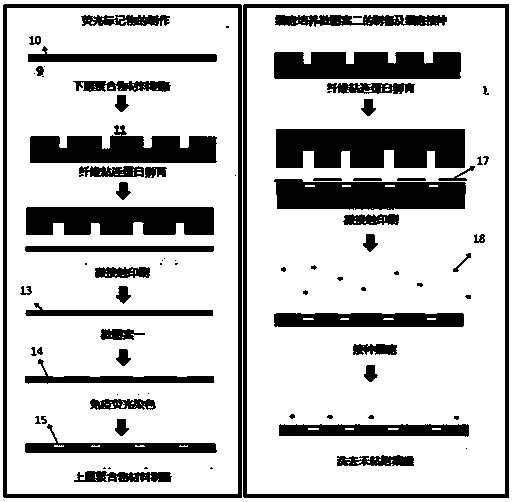

[0052] The present invention will be further described below in conjunction with specific drawings and embodiments.

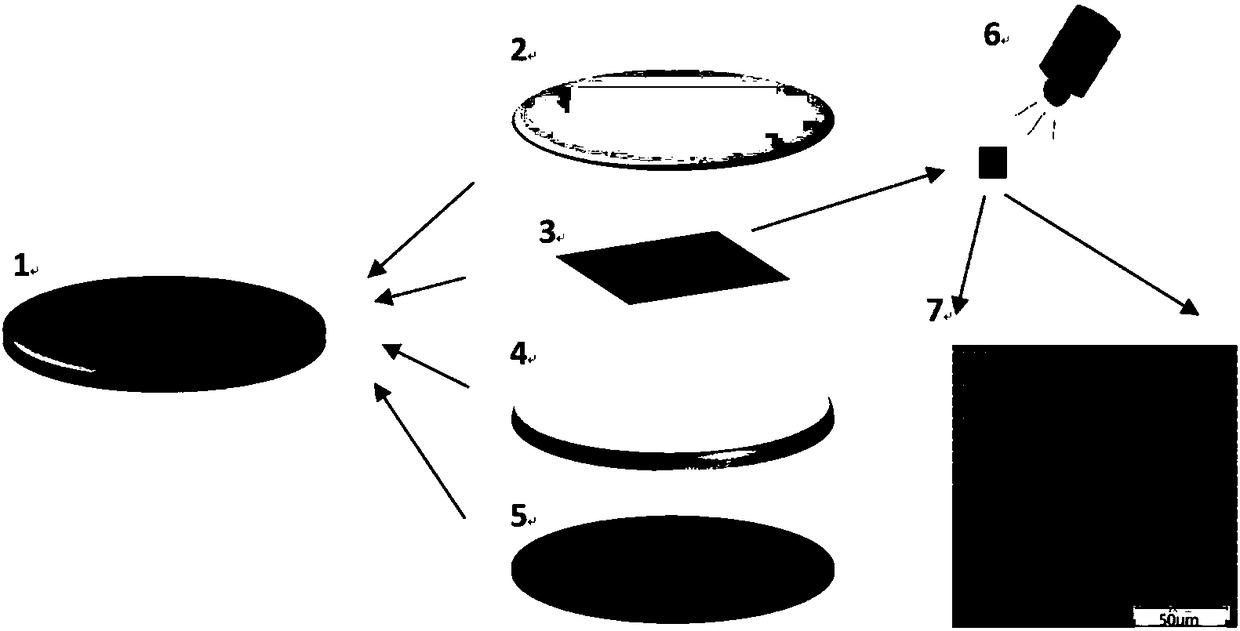

[0053] The invention relates to a mechanical measurement chip of skeletal muscle myotubes, which can accurately and efficiently measure the mechanical strength of skeletal muscle myotubes during contraction, and can be applied in scientific research in the field of biomedical engineering. The chip for measuring skeletal muscle myotube mechanics consists of a glass slide, a double-layer polymer material substrate and immune markers. As the base of the whole chip, the glass slide acts as a support and stabilizer; the polymer material is divided into two layers, the lower layer is thicker, and the speed of the glue homogenizer is controlled above 38 μm, and the upper layer is controlled within 10 μm; the immune marker is used as The core element in this invention is sandwiched between two layers of polymer materials, close to the upper surface, so as to achieve th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com