Stable fat-soluble active component composition, and microcapsule, preparation method and applications thereof

An active ingredient and fat-soluble technology, which is applied in the field of new green antioxidant compositions, can solve the problems that the dosage and antioxidant ratio are not clearly described, and the combined use of antioxidants is not mentioned, so as to achieve the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Under nitrogen protection, vitamin A crystallization, vitamin C palmitate and α-tocopherol were melted at 75°C to prepare vitamin A melt oil. The weights of vitamin A, vitamin C palmitate, and α-tocopherol were determined according to the factor level setting table in Table 1 and the orthogonal experiment arrangement table in Table 2. The vitamin A melted oil was put in a sampling bottle, sealed and protected from light, stored at 40°C, and its content was detected after 0, 2, 4, and 6 days respectively.

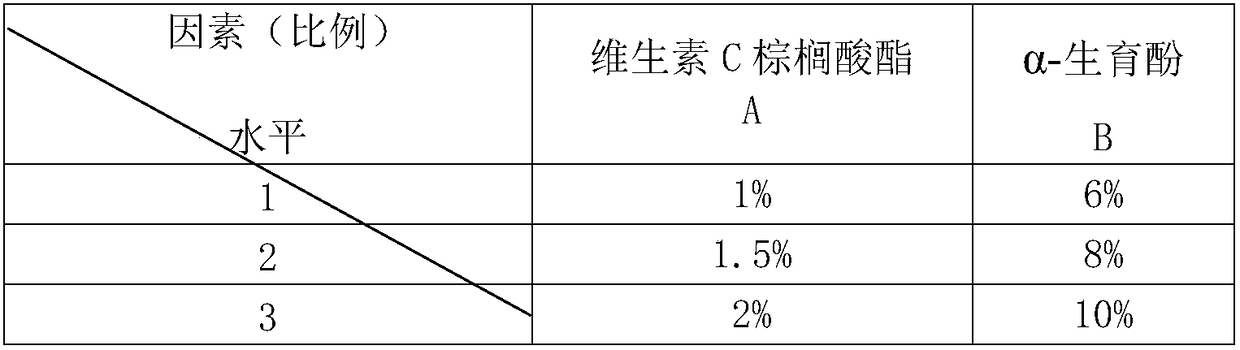

[0039] Table 1 Factor level setting table

[0040]

[0041] Remarks: The percentage values in the table are the ratio of antioxidants to vitamin A

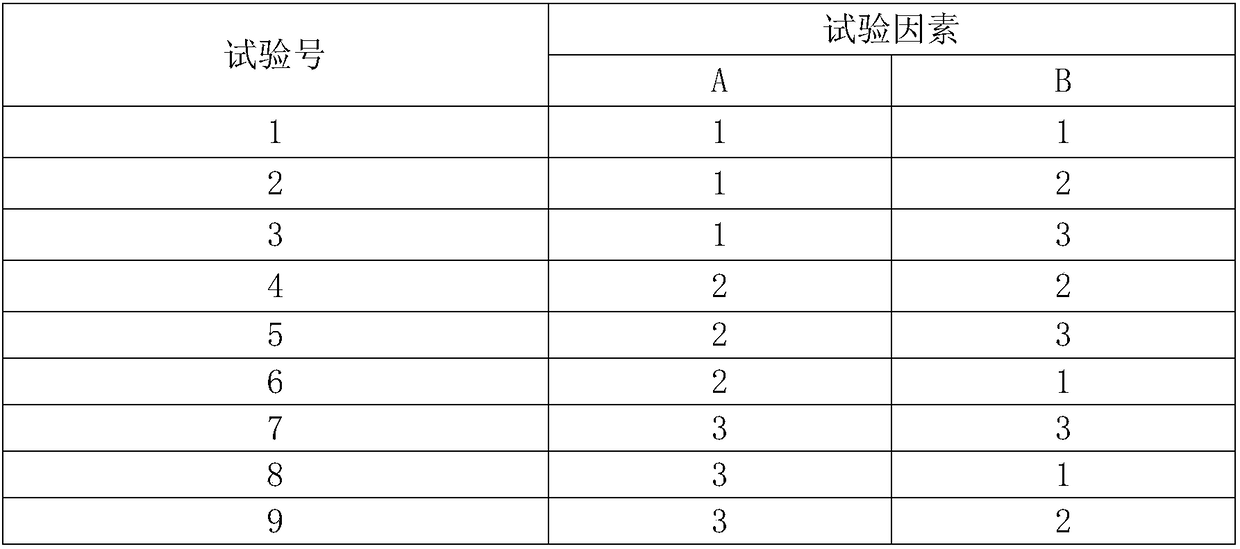

[0042] Table 2 Arrangement of Orthogonal Experiments

[0043]

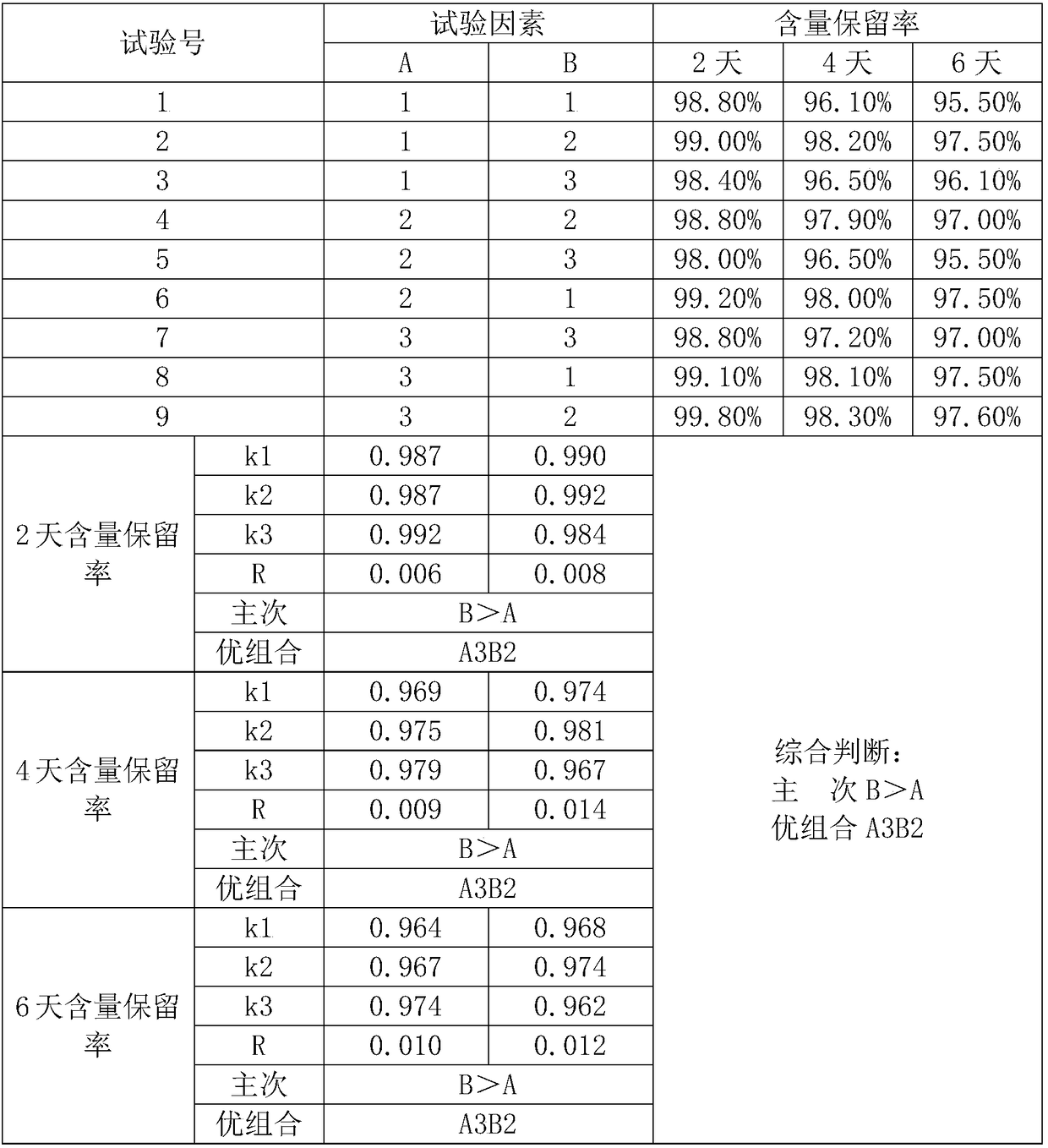

[0044] The results of 2 days, 4 days, and 6 days were analyzed respectively, and the comprehensive judgment was used as the final experimental result to conduct a range analysis on the content retention rate, and select the primary and secondary rel...

Embodiment 2

[0049] Under the protection of nitrogen, melt the mixture of vitamin A palmitate, vitamin C palmitate and β-tocopherol at 65°C to prepare vitamin A palmitate melt oil. Dissolve gelatin and glucose in water at 65°C to form an aqueous solution of gelatin and glucose. Under high-speed shearing conditions, the vitamin A palmitate melted oil is poured into the above-mentioned aqueous phase solution for emulsification, degassing, and homogenization to obtain a stable emulsion. The vitamin A palmitate emulsion was placed in a sampling bottle, sealed and protected from light, stored at 40°C, and its content was detected after 0, 1, 2, and 3 weeks, respectively. The retention rate data of emulsion content in different antioxidant ratios are shown in Table 4 below.

[0050] Table 4. Statistical table of content retention rate of different antioxidant combinations in vitamin A palmitate emulsion

[0051]

[0052] It is evident from the data in Table 4 that within the range of the fo...

Embodiment 3

[0054] Under the protection of nitrogen, 50 kg of vitamin A acetate crystallization, 0.5 kg of vitamin C palmitate and 3.5 kg of synthetic mixed tocopherols were melted at 85°C to prepare vitamin A acetate melt oil. 75 kilograms of gelatin and 50 kilograms of glucose are dissolved in 130 kilograms of 60 ℃ of water, are made into 49% gelatin glucose aqueous phase solution.

[0055] Under high-speed shearing conditions, pour vitamin A acetate melted oil into the above water phase solution for emulsification, degassing, and homogenization to obtain a stable emulsion, which is sent to the starch bed for spray granulation, then fluidized drying, high temperature After cross-linking, 218 kg of water-repellent vitamin A acetate microcapsules were obtained. Through HPLC analysis, the vitamin A acetate content is 520,000 IU / g, and the microencapsulation yield is 95%. The vitamin A ester microcapsules were placed in a sampling bottle to be sealed and protected from light. After being s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com