Waterborne shoe material silk-screen printing ink and preparation method thereof

A technology for screen printing ink and shoe material, applied in the field of water-based shoe material screen printing ink and its preparation, can solve the problems of further improvement of printing and leveling performance, human injury, environmental pollution, etc. Good anti-aging effect and reduce production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The technical solutions of the present invention will be further described below through specific embodiments.

[0046] Unless specifically stated, various raw materials of the present invention can be purchased commercially, or can be prepared according to conventional methods in the art.

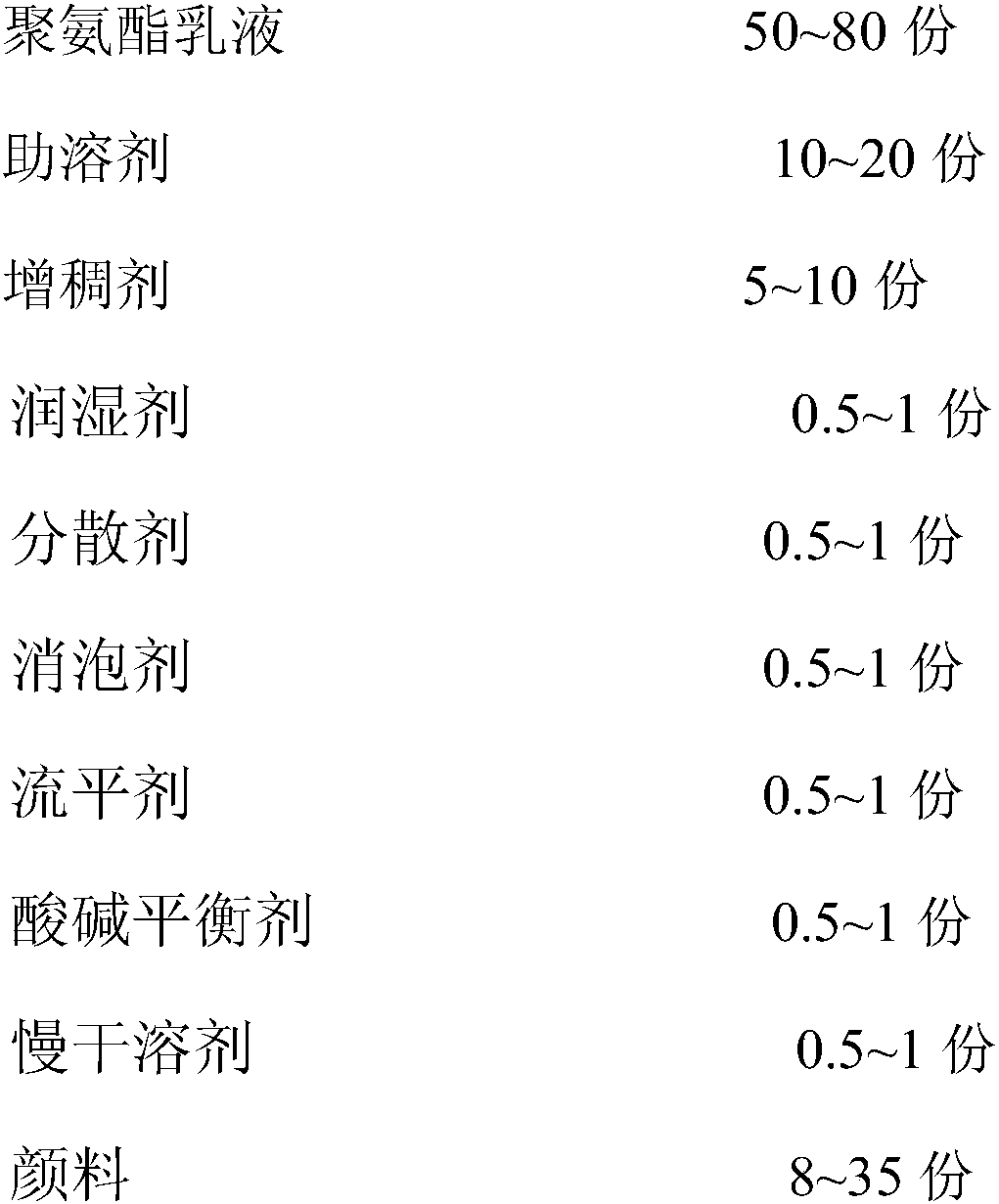

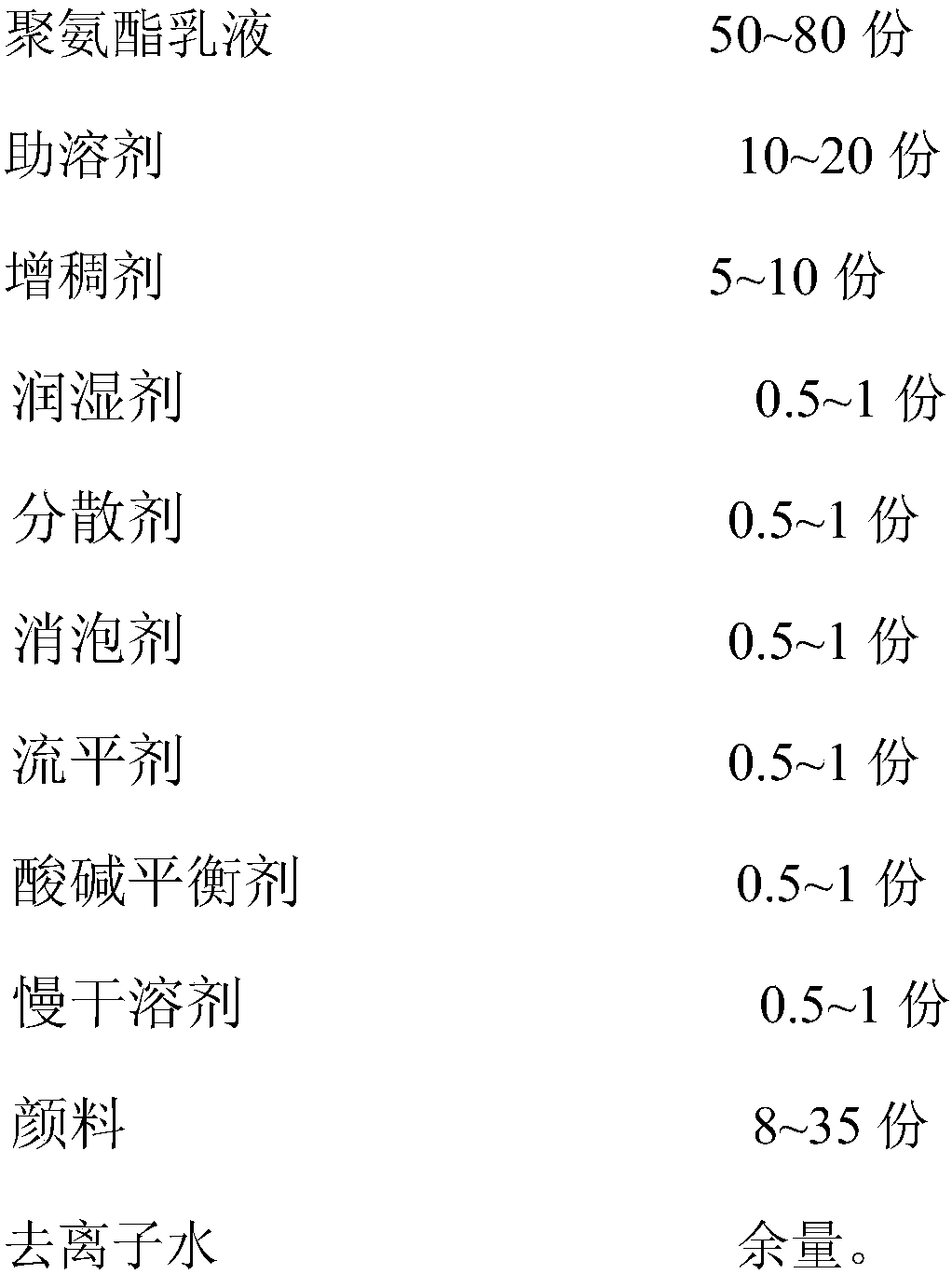

[0047] Water-based shoe material silk screen printing ink of the present invention, by weight, the preparation raw material of described water-based shoe material silk screen printing ink comprises following components:

[0048]

[0049] The preparation method of water-based shoe material screen printing ink of the present invention comprises the steps:

[0050] 1) In parts by weight, add 10-20 parts of cosolvent and 5-10 parts of thickener to 50-80 parts of polyurethane emulsion, and stir to dissolve;

[0051] 2) In parts by weight, add 0.5-1 part of wetting agent, 0.5-1 part of dispersing agent, 0.5-1 part of defoamer, and 0.5-1 part of leveling agent to the mixture obtained in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com